Compressor and its control method and air conditioner

A technology of compressors and flow regulating valves, which is applied in the direction of machines/engines, mechanical equipment, pump combinations for elastic fluid rotary piston type/swing piston type, etc., to achieve effective cooling, adapt to a wide range of working conditions, and improve reliability Effect

Active Publication Date: 2018-02-13

ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Based on this, it is necessary to solve the problem that the compressor can adapt to the poor range of working conditions. The purpose of the present invention is to provide a compressor and its control method and an air conditioner, which can realize multi-stage switching or capacity adjustment of the compressor, and is compatible with scroll Advantages of type compressor and rotary compressor, suitable for a wide range of working conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0057] As an implementable manner, the control method also includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

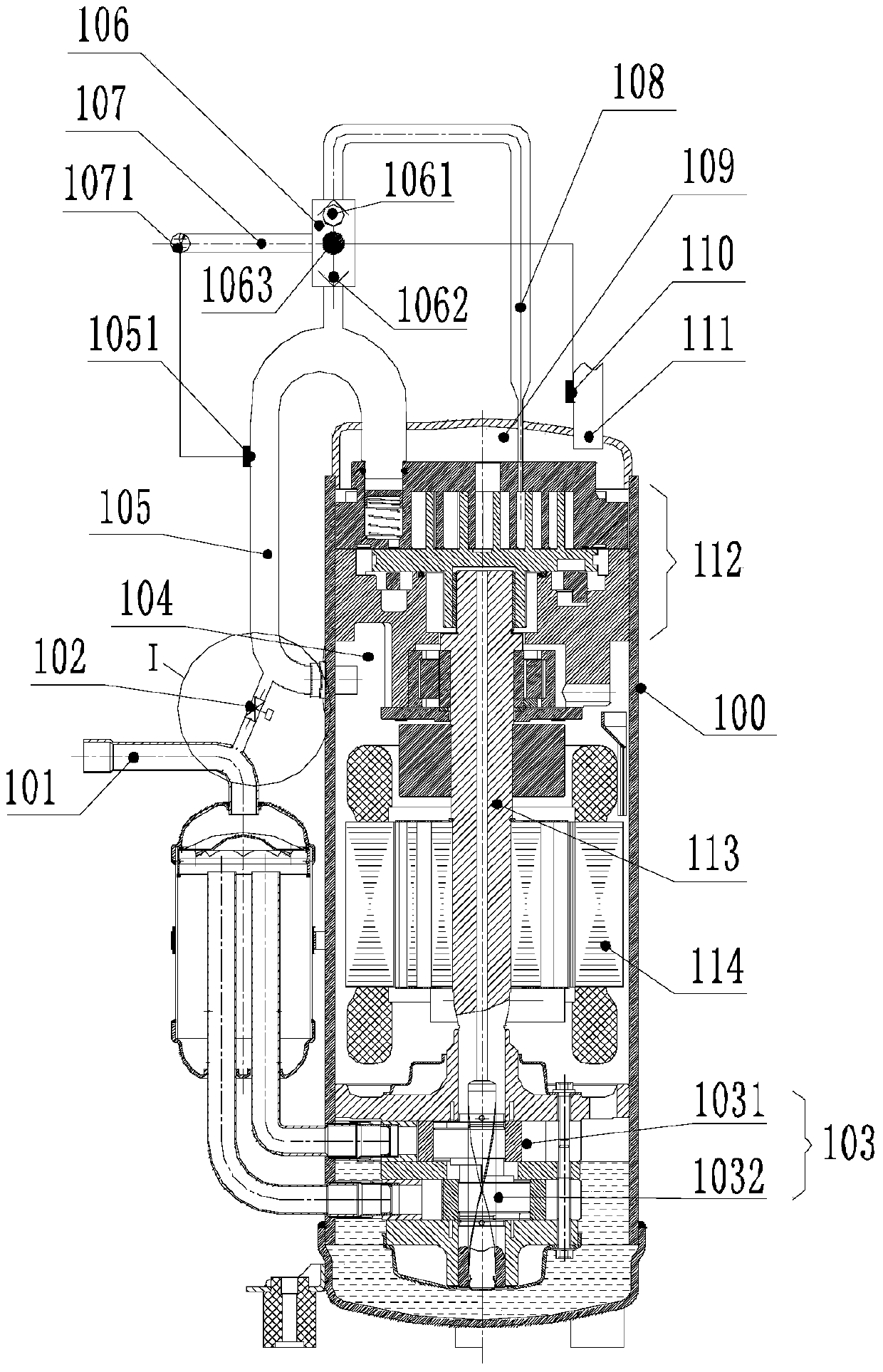

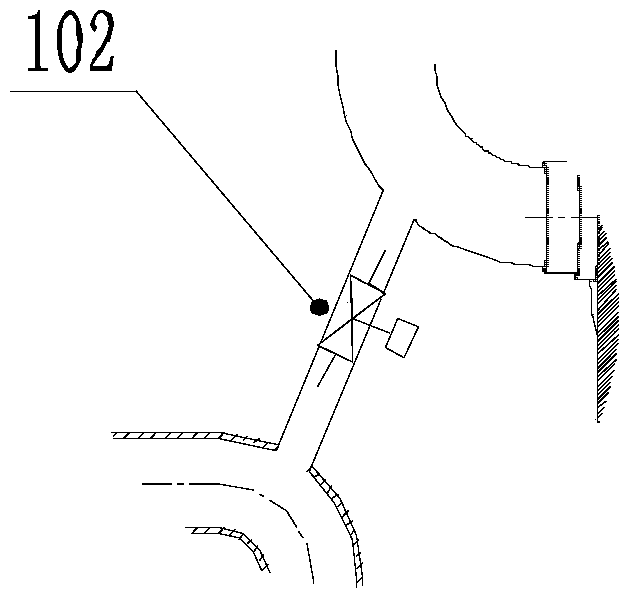

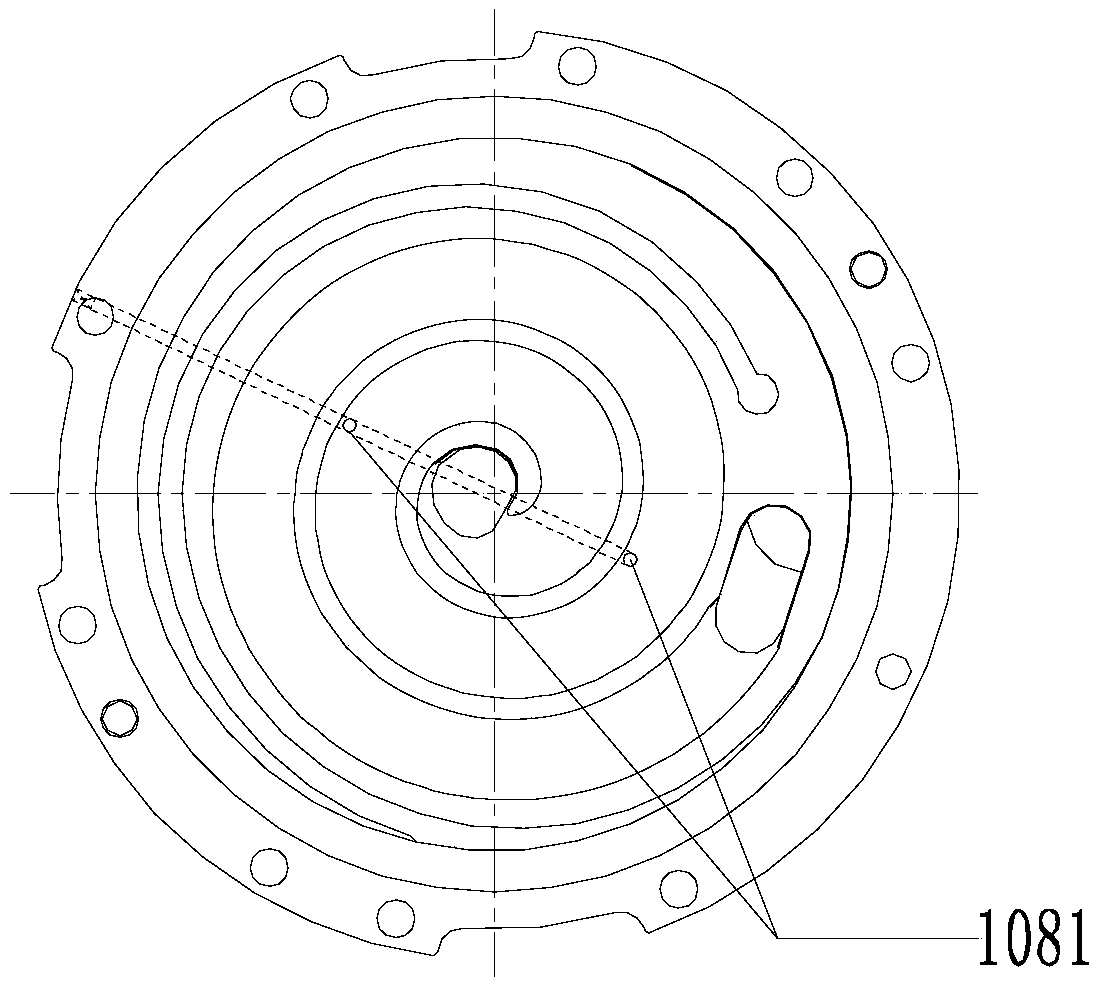

The invention provides a compressor. The compressor comprises a shell, a compressing assembly, a motor and a crankshaft, wherein the compressing assembly, the motor and the crankshaft are arranged in the shell; the motor drives the compressing assembly to rotate through the crankshaft, the compressing assembly comprises a rotor type pump body assembly and a vortex type pump body assembly which are arranged on the two sides of the motor respectively, and an air outlet pipe is arranged on the shell; an air inlet of the vortex type pump body assembly is communicated with an air outlet of the rotor type pump body assembly, air compressed by the vortex type pump body assembly is output through the air outlet pipe; to-be-compressed air is sucked into the rotor type pump body assembly through the air inlet of the rotor type pump assembly, and the air inlet of the rotor type pump assembly can be optionally communicated with the air inlet of the vortex type pump body. The invention further relates to a control method of the compressor and an air conditioner. According to the compressor, the control method thereof and the air conditioner, the effect of multilevel switching or capacity adjusting of the compressor is achieved; in addition, the compressor is compatible with the advantages of a vortex type compressor and a rotating type compressor and suitable for a wide working condition range.

Description

technical field [0001] The invention relates to the technical field of refrigeration, in particular to a compressor, a control method thereof, and an air conditioner. Background technique [0002] Ordinary scroll compressors are only suitable for some specific working conditions. When the condensing temperature is constant, the following problems will occur when the ordinary scroll compressor operates at a low evaporation temperature: 1) The suction specific volume increases, and the refrigerant cycle 2) The pressure ratio increases, the volumetric efficiency decreases, and the air delivery volume and energy efficiency of the compressor drop significantly; 3) The exhaust gas temperature rises rapidly, causing the viscosity of the lubricating oil to drop sharply, affecting the lubrication of the compressor. When the exhaust temperature is close to the flash point of the lubricating oil, it will carbonize the lubricating oil. Contents of the invention [0003] Based on this...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F04C23/00F04C28/02

CPCF04C23/00F04C28/02

Inventor 马英超胡余生单彩侠康小丽

Owner ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com