Exhaust casing assembly used for test piece of gas compressor

A technology of assemblies, exhaust machines, applied in the direction of components of pumping devices for elastic fluids, machines/engines, pump elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

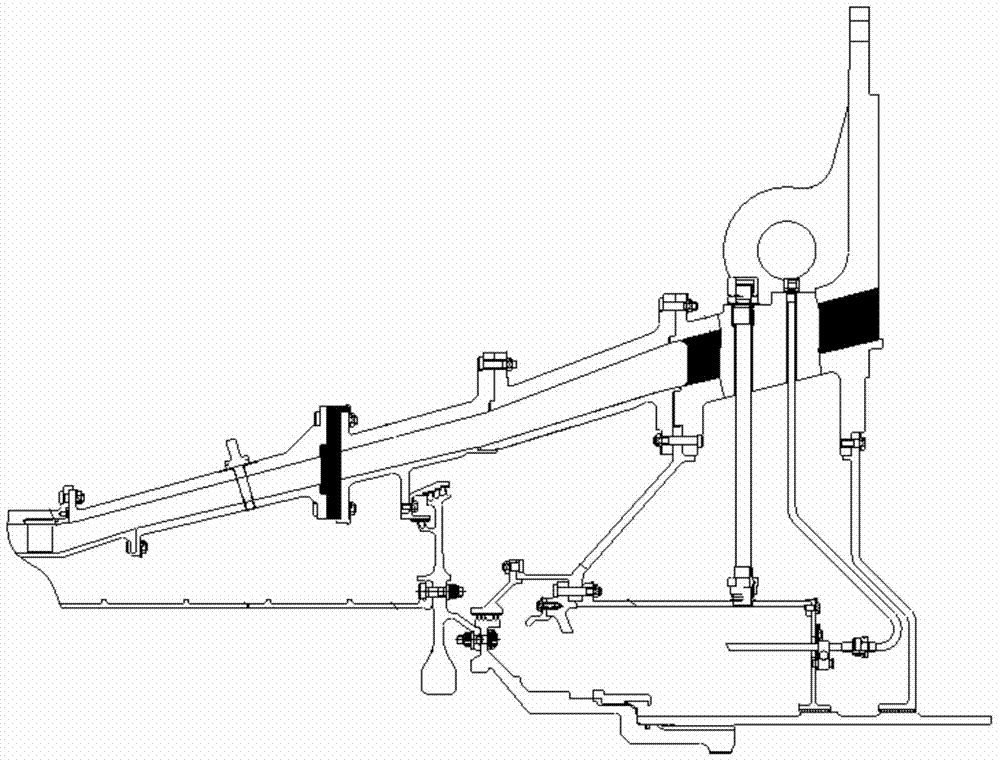

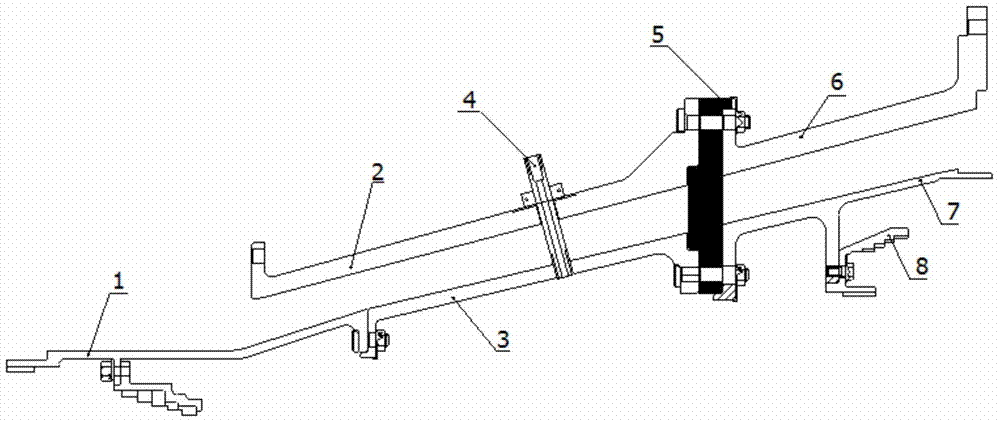

[0019] The invention provides an exhaust casing assembly that can be used for a compressor test piece, and is characterized in that: the exhaust casing assembly that can be used for a compressor test piece includes an outlet casing assembly 1, an exhaust Air outer ring front section 2, exhaust inner ring front section 3, test lead pipe 4, exhaust casing connecting ring 5, exhaust outer ring rear section 6, exhaust inner ring rear section 7, balance disk sealing ring 8;

[0020] Among them: a complete casing assembly is formed through the assembly of the exhaust casing coupling ring, the front outlet casing assembly 1 is connected to the compressor outlet, and the rear section 7 of the rear exhaust outer ring is exhausted after the compressor test piece Sectional connection, while the outlet casing assembly 1 and the rear section 7 of the exhaust outer ring are overlapped with the front and rear parts, and the components are exported casing assembly 1, the front section 3 of the...

Embodiment 2

[0028] The invention provides an exhaust casing assembly that can be used for a compressor test piece, and is characterized in that: the exhaust casing assembly that can be used for a compressor test piece includes an outlet casing assembly 1, an exhaust Air outer ring front section 2, exhaust inner ring front section 3, test lead pipe 4, exhaust casing connecting ring 5, exhaust outer ring rear section 6, exhaust inner ring rear section 7, balance disk sealing ring 8;

[0029] Among them: a complete casing assembly is formed through the assembly of the exhaust casing coupling ring, the front outlet casing assembly 1 is connected to the compressor outlet, and the rear section 7 of the rear exhaust outer ring is exhausted after the compressor test piece Sectional connection, while the outlet casing assembly 1 and the rear section 7 of the exhaust outer ring are overlapped with the front and rear parts, and the components are exported casing assembly 1, the front section 3 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com