Impact-resistant fluoroplastic heat exchanger

A fluoroplastic heat exchanger, anti-shock technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of increasing leak detection, blocking and maintenance, damaged tube bundles, and insufficient strength of fluoroplastic tube bundles and other problems to achieve the effect of improving operational reliability and reducing leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

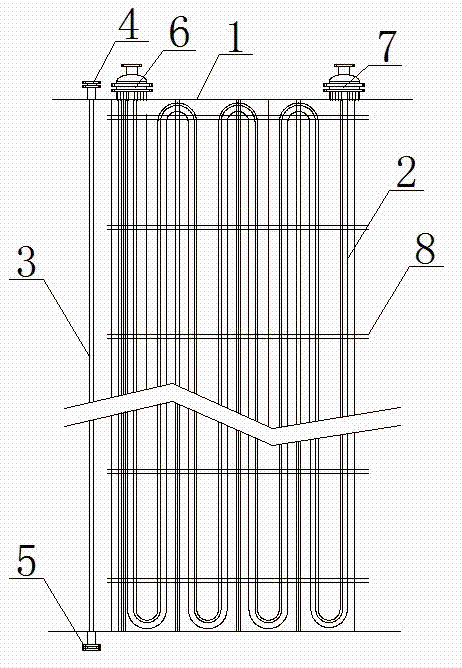

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a flue 1, a fluoroplastic heat exchanger 2 is arranged inside the flue 1, and a number of anti-shock tube bundles 3 are arranged in front of the fluoroplastic heat exchanger 2. The upper and lower ends of the anti-shock tube bundle 3 are fixedly connected to the flue 1 through the upper head 4 and the lower head 5 respectively. The anti-shock tube bundle 3 is 4 rows. The anti-shock tube bundle 3 is a fluoroplastic tube with a diameter of 10 mm and a thickness of 1 mm. The inlet and outlet of the 2 tube rows of the fluoroplastic heat exchanger are respectively connected with an inlet joint flange 6 and an outlet joint flange 7 , and the 2 tube rows of the fluoroplastic heat exchanger are fixed by a fixing frame 8 . The fixed frame 8 is made of carbon steel winding fiberglass material.

[0016] Using the anti-shock fluoroplastic heat exchanger of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com