A Constant Volume Combustion Device for Studying Spray Form and Its Microscopic Characteristics

A constant volume combustion and microscopic technology, applied in the direction of internal combustion engine testing, etc., can solve the problem that the structure of constant volume combustion projectile is not optimized enough, cannot effectively measure the macroscopic morphology and microscopic characteristics of various fuel sprays synchronously, and cannot apply multiple fuel injection systems, etc. problems, to achieve the effect of improving observation and shooting effects, improving observation data and measurement effects, and increasing data collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

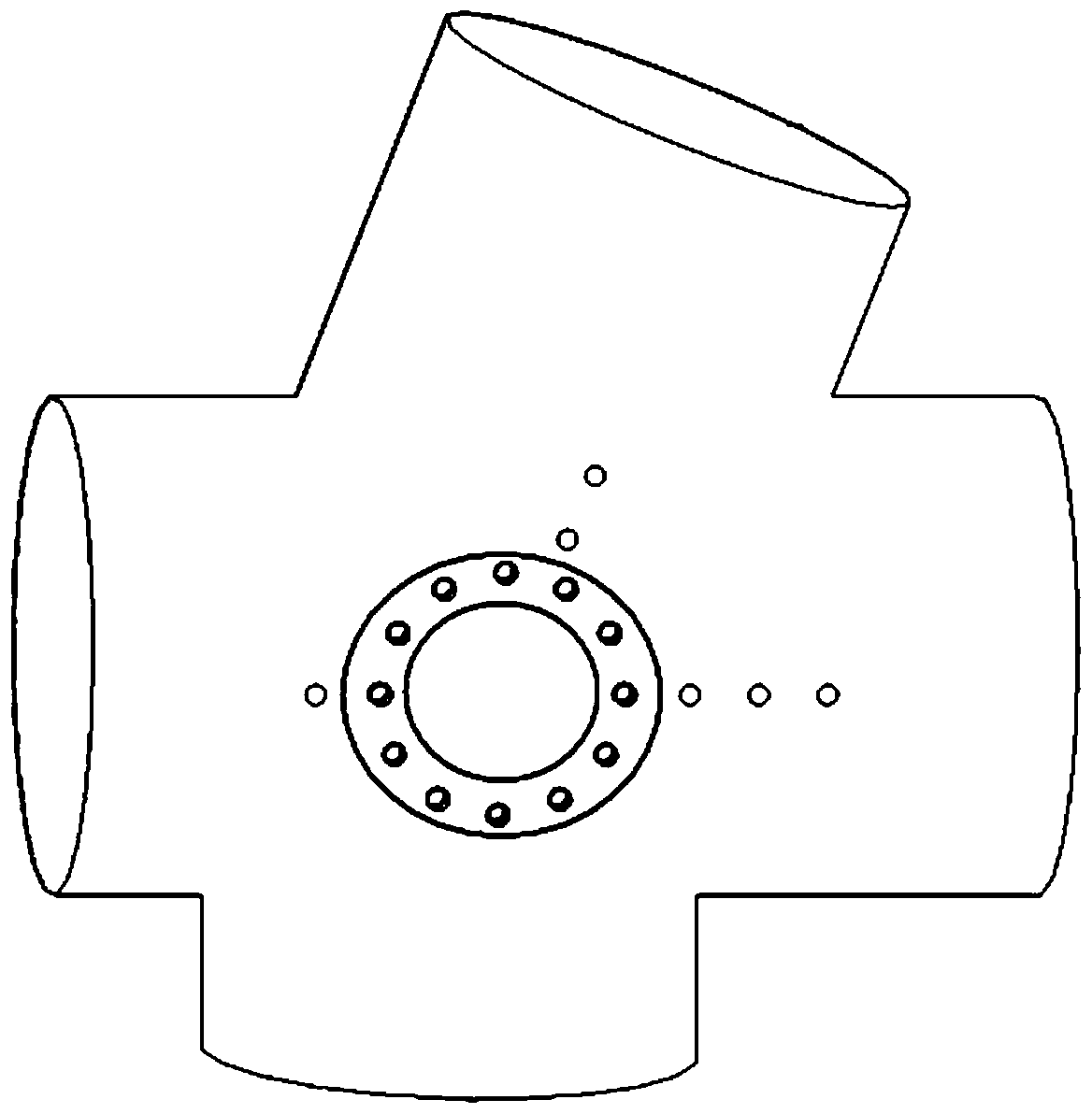

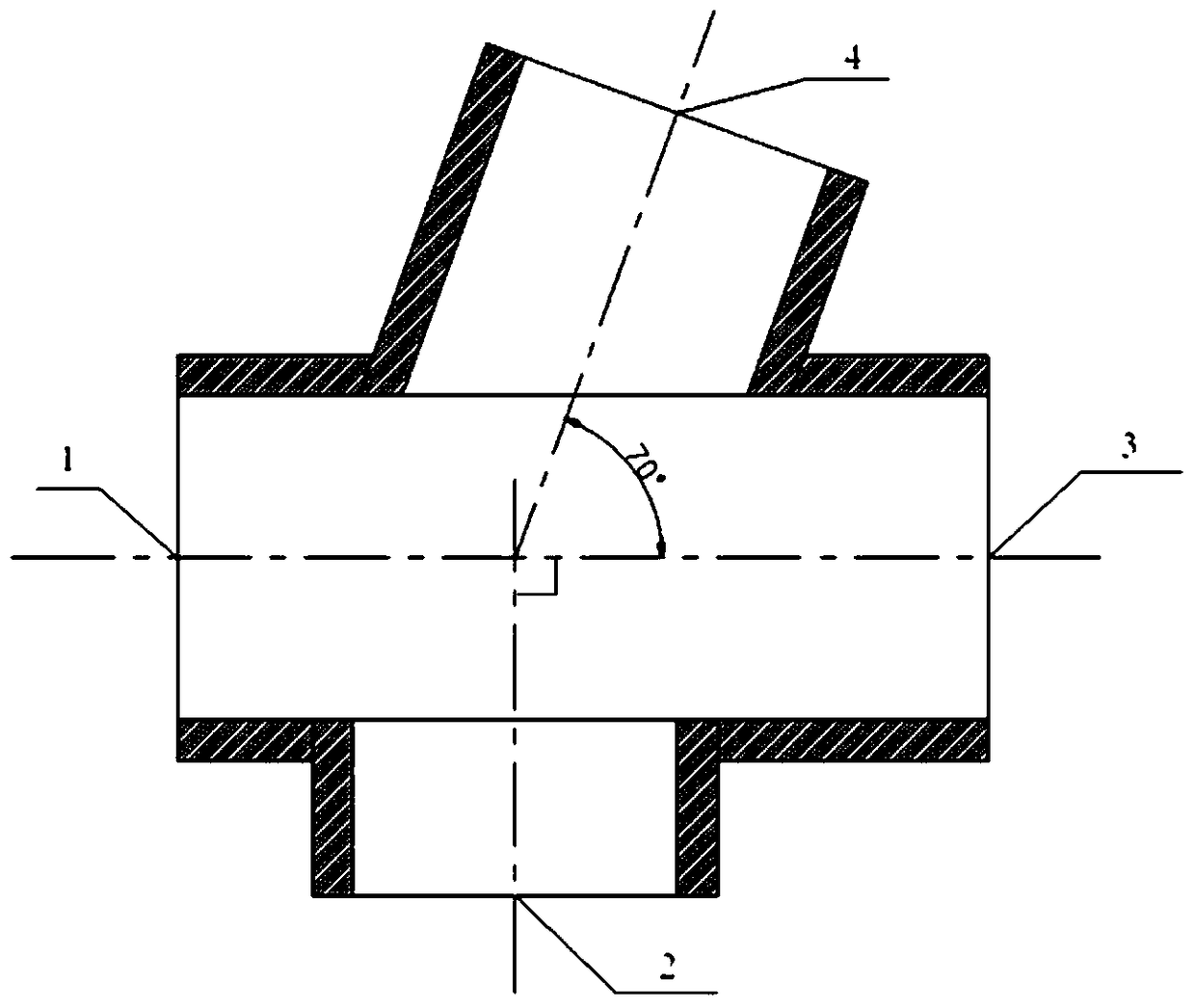

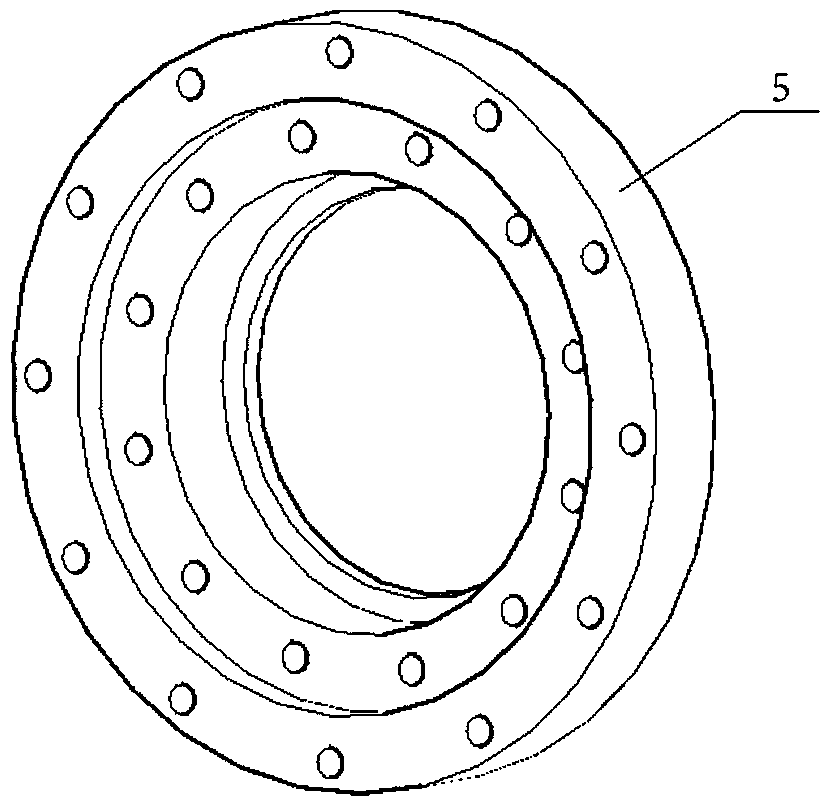

[0029] A constant-volume combustion device for studying the spray form and its microscopic characteristics, including a combustion bomb installed inside the box, such as figure 1 As shown, the incendiary bomb body is provided with four observation holes in the shape of through holes, the axes of the observation holes are all on the same horizontal plane, and the angle between the axes of the two observation holes is 180°, and the axes of the other two observation holes The angle between them is 160°; if figure 2 As shown, optical observation windows 1, 2, 3, and 4 are correspondingly arranged on the observation holes, such as image 3 , Figure 4 and Figure 5 As shown, the optical observation window is composed of port flange 5, optical glass and glass gland 6. The port flange 5 is installed in the observation hole through the inner hexagonal bolt, the optical glass i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com