Detonation tube structure of a rotary air-breathing pulse detonation engine

A pulse detonation and detonation tube technology, applied in mechanical equipment, intermittent injection devices, etc., can solve the problems of low fuel utilization, reduce the layout space of the detonation tube, shorten the length of the detonation tube of the detonation engine, etc. Increased reliability, favorable combustion, favorable formation and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with accompanying drawing:

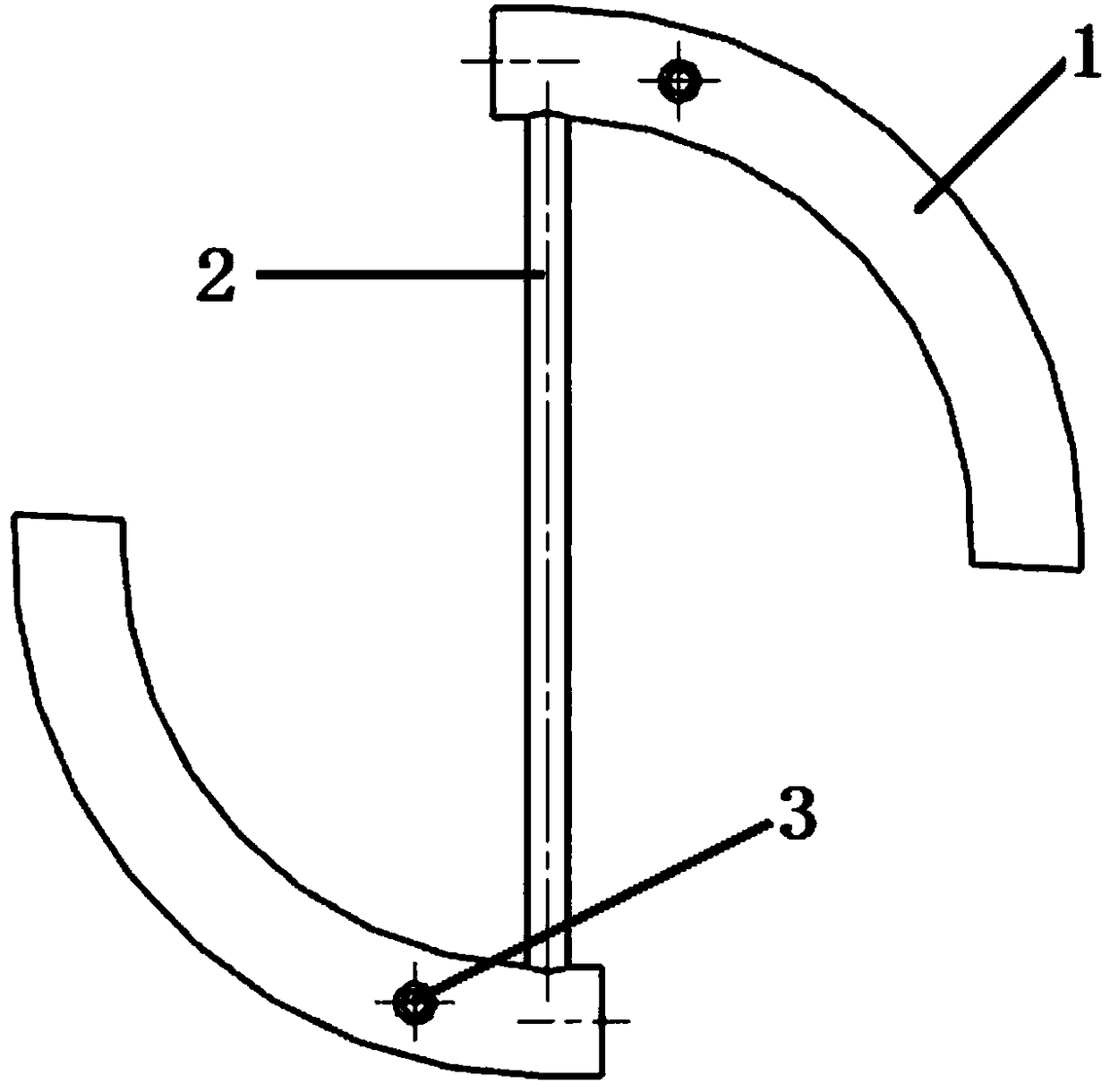

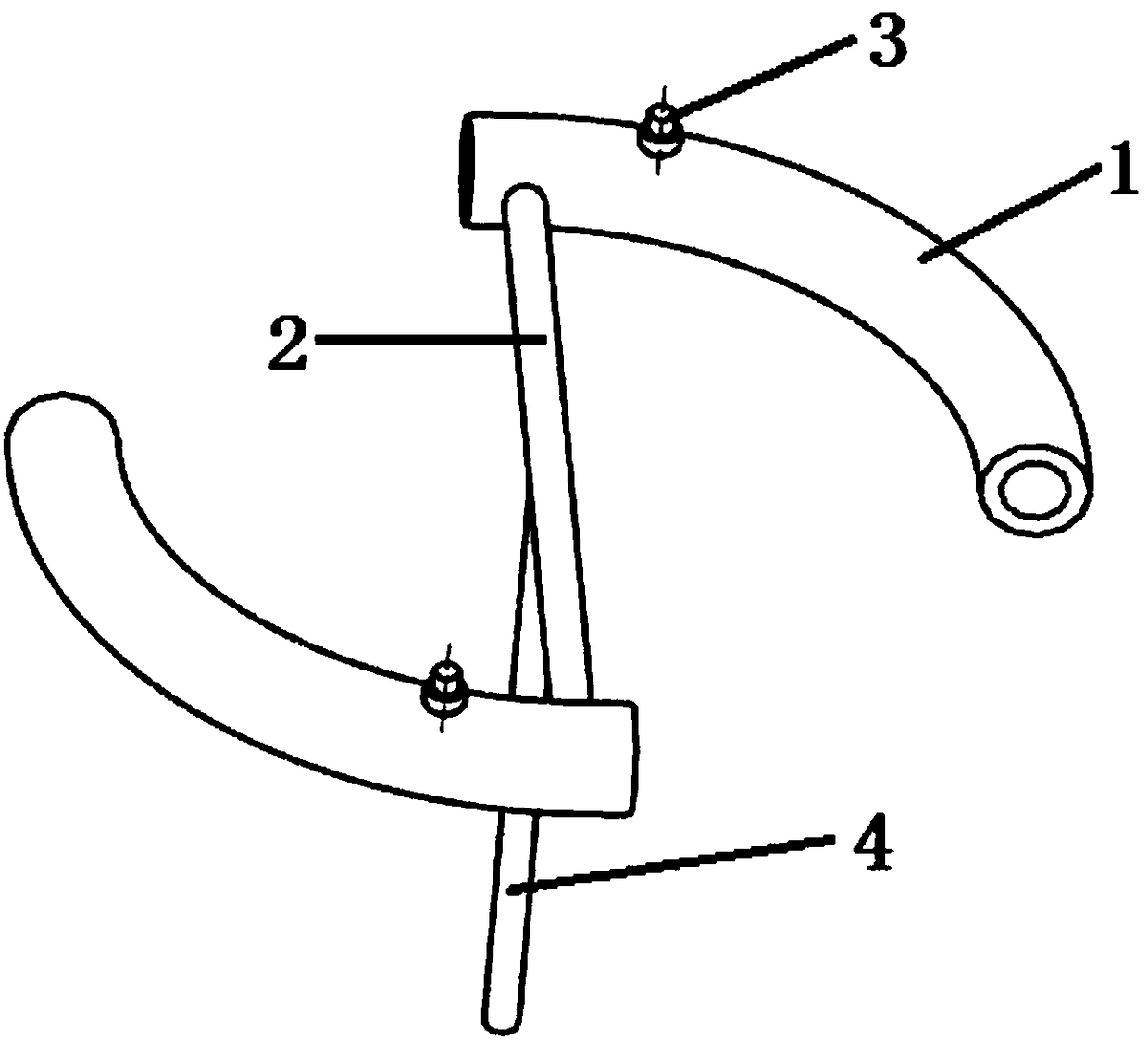

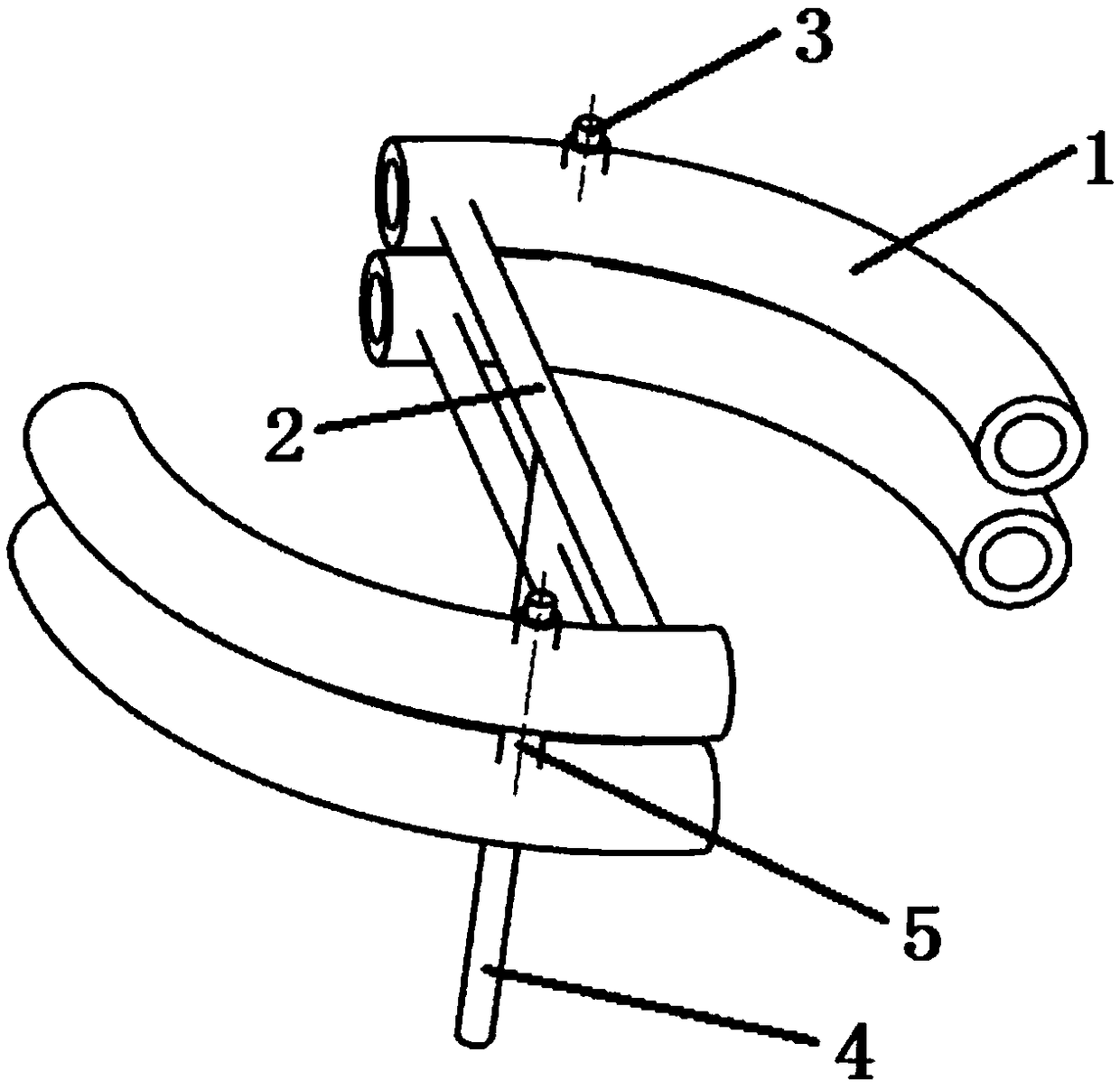

[0018] combine figure 1 with figure 2 , The present invention proposes a detonation tube structure of a rotary air-breathing pulse detonation engine capable of generating rotary detonation force. figure 1 It is a structural schematic diagram of a rotary detonation tube, and the detonation tube of a rotary air-breathing pulse detonation engine includes a detonation tube (1), a fuel injection tube (2) and a spark plug (3). The detonation tube (1) is a rotating circumferential structure, and there are two detonation tubes (1), the length of which is 1 / 4 of the perimeter, and the distribution is center-symmetrical. In addition, the detonation tube (1) ) also has a section of straight pipe structure at the entrance. The two ends of the fuel injection pipe (2) are respectively connected and installed on the inner pipe wall of the straight pipe type detonation pipe at the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com