Rotary automatic light inspection machine

An automatic light inspection machine and rotary technology, which is applied in the automatic field of detection of foreign objects in bottles, can solve the problems of camera and bottle to be detected cannot be maintained, inevitable camera vibration, detection errors, etc., and achieve low power consumption and small size , a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

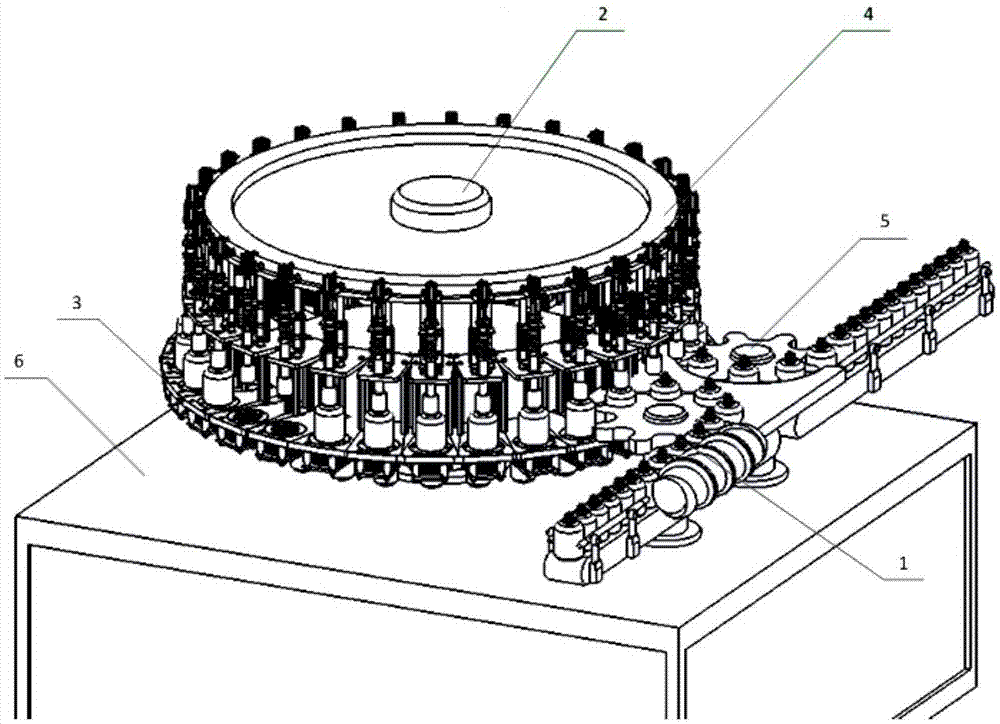

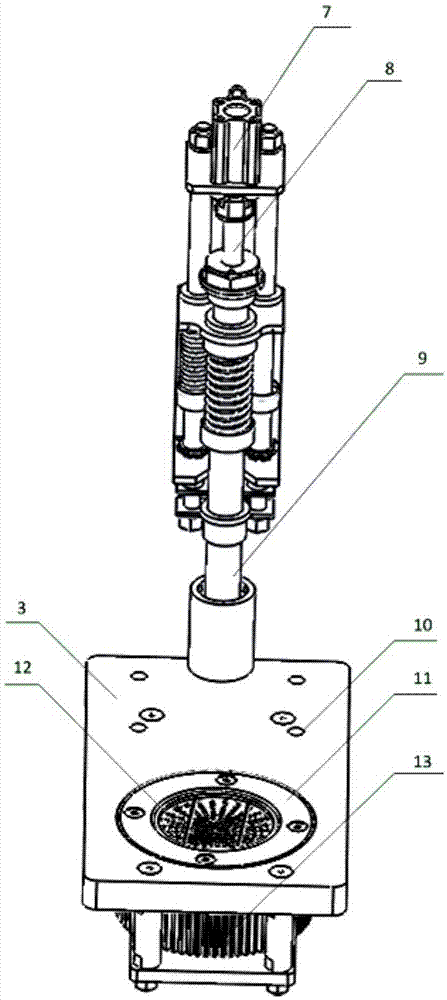

[0026] Such as figure 1 and figure 2 As shown, the structural diagram of the present invention includes a rotary transmission device, a single-head detection device and a rejecting device. The rotary transmission device includes a bottle-in auger and a dial 1, a rotating shaft 2, a rotating bottle tray 3, a rotating cam 4, and a The bottle auger and the dial 5, the rotating shaft 2 is driven by a motor, the rotating shaft 2 is installed on the base bracket 6, the rotating bottle tray 3 and the rotating cam 4 are coaxially installed on the rotating shaft 2 up and down and rotate together, the bottle feeding auger Dragon and dial 1 is located between the bottle inlet track and the bottle inlet of the bottle tray, and is responsible for dialing the bottle to be tested into the bottle pressing tray of the bottle tray, and the bottle output auger and dial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com