Interference fit structure and method

A technology of interference fit and structural size, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems that ordinary machines are difficult to adapt to strong magnetic field environments, difficult to machine, and damage winding heads, etc. Small deformation, eliminating the trouble of dealing with strong magnetic fields, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

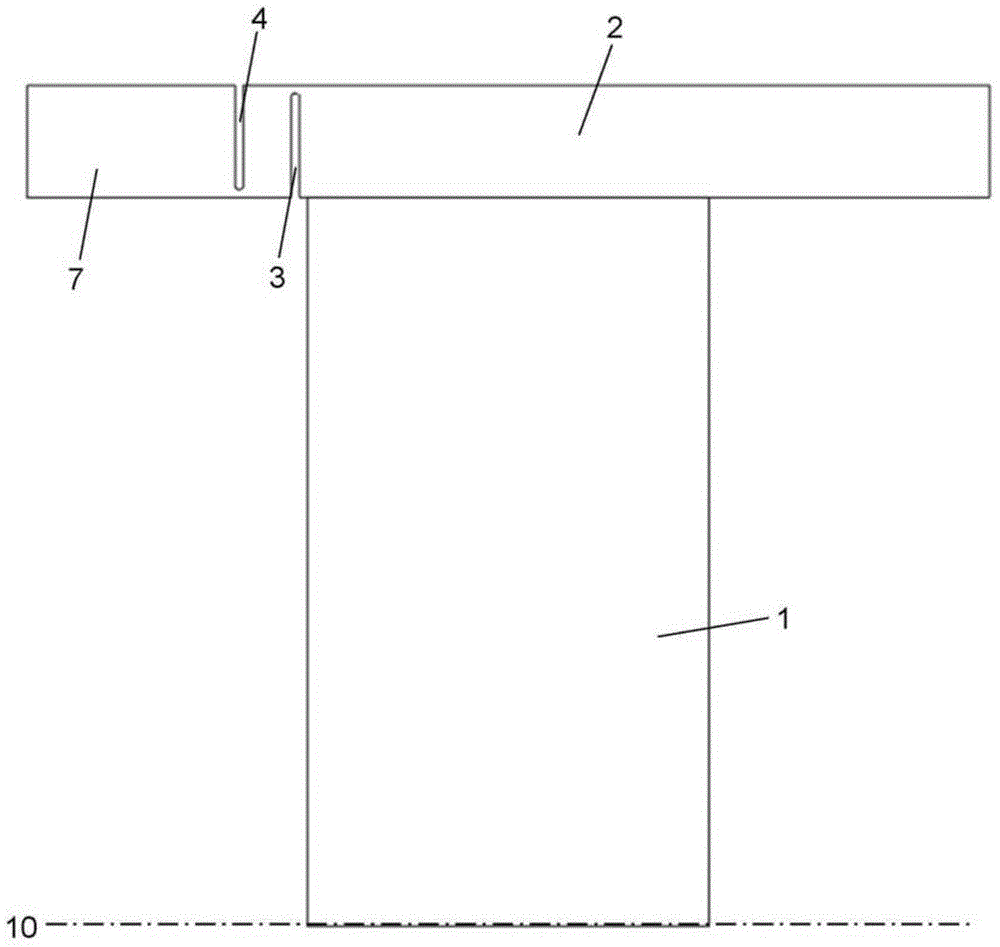

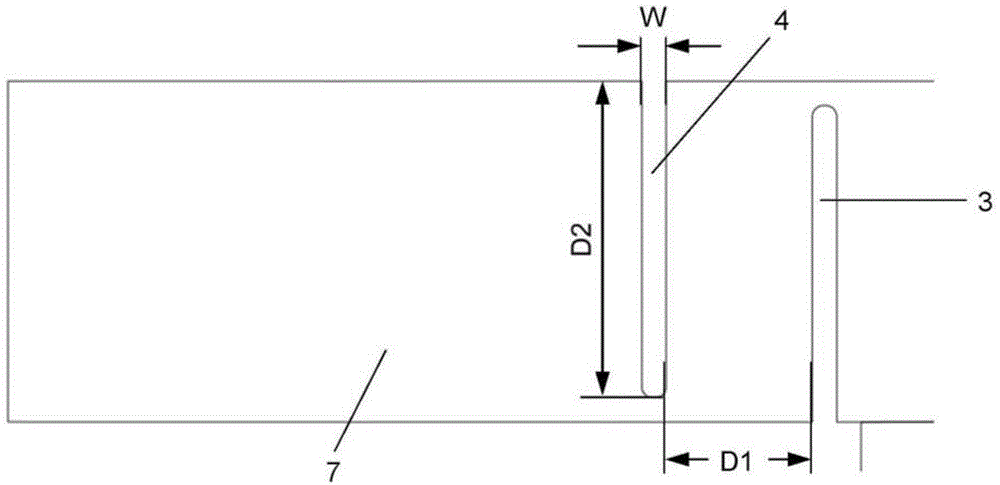

[0044] The basic idea of the invention is to incorporate mechanical compliance means, in particular at least two grooves, in the end region of the outer part of the two parts to be interference fitted, in order to reduce the strain on the outer part caused by the interference fit. The cone angle formed by the end region of the outer part, wherein at least one groove is provided on the inner side and the outer side of the outer part.

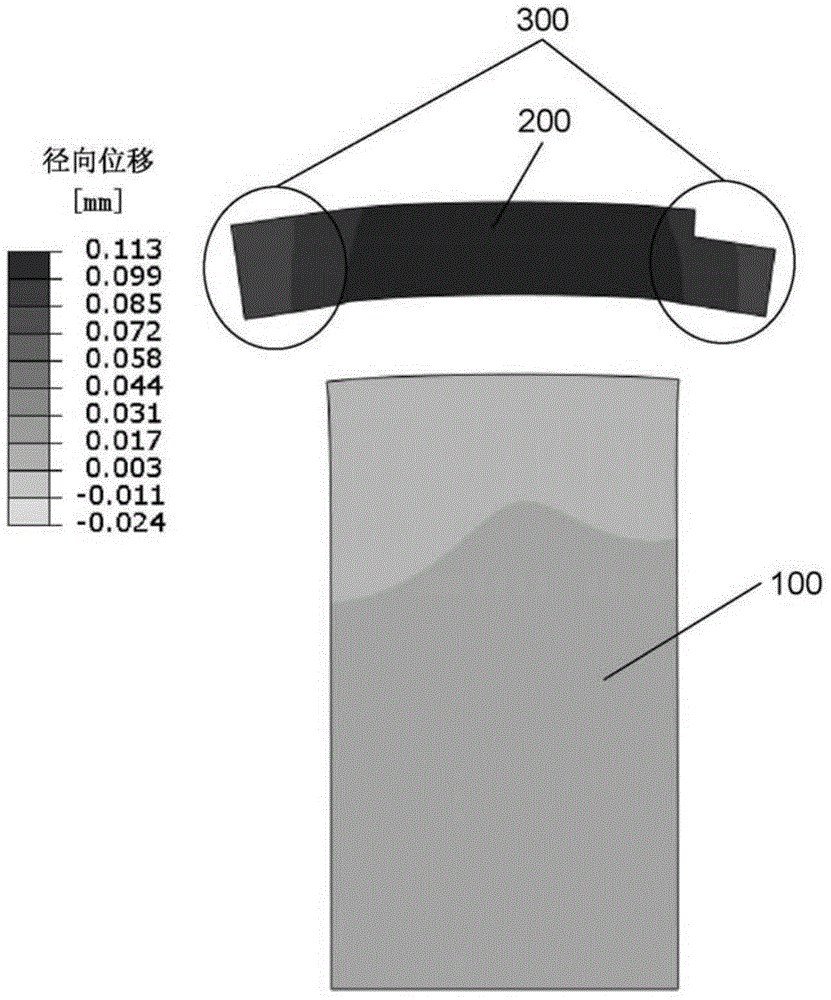

[0045] figure 2 It is a schematic cross-sectional view of a part of the stator and the cooling water jacket of the motor under the condition that the stator of the motor and the cooling water jacket of the motor are assembled using an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com