Magnetic transmission device having coupling, separation and reunion and speed regulation functions and mounting method thereof

A magnetic transmission and functional technology, applied in permanent magnet clutches/brakes, asynchronous inductive clutches/brakes, electromechanical devices, etc., can solve problems affecting the quality of power grid power supply, motor overheating, grid frequency harmonic interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

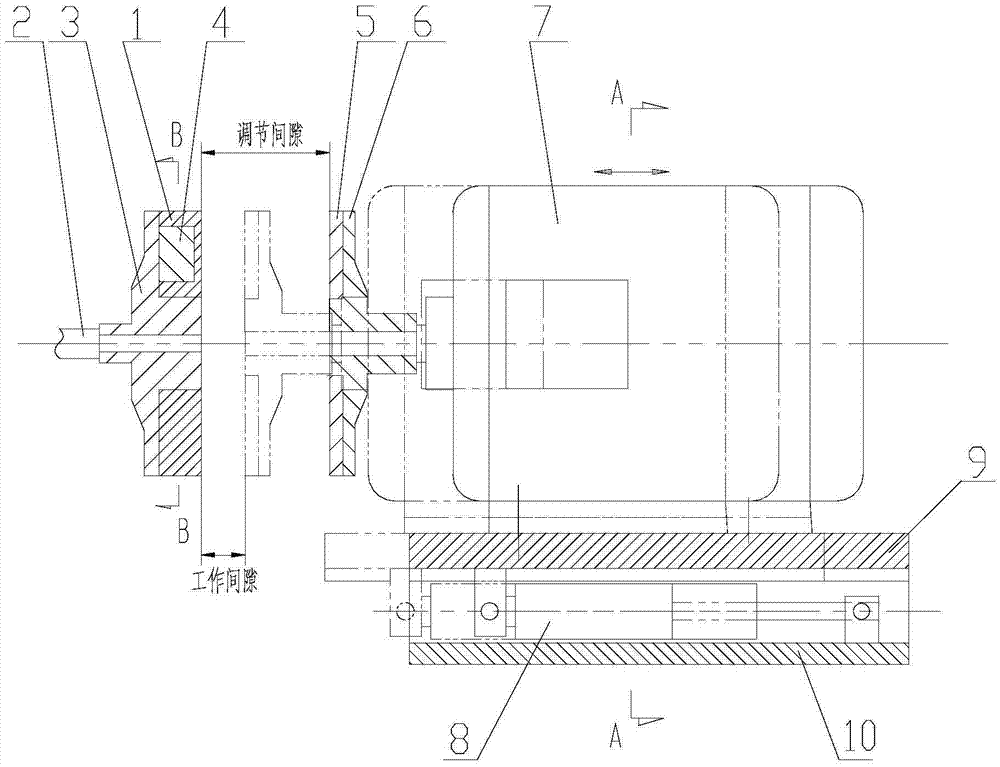

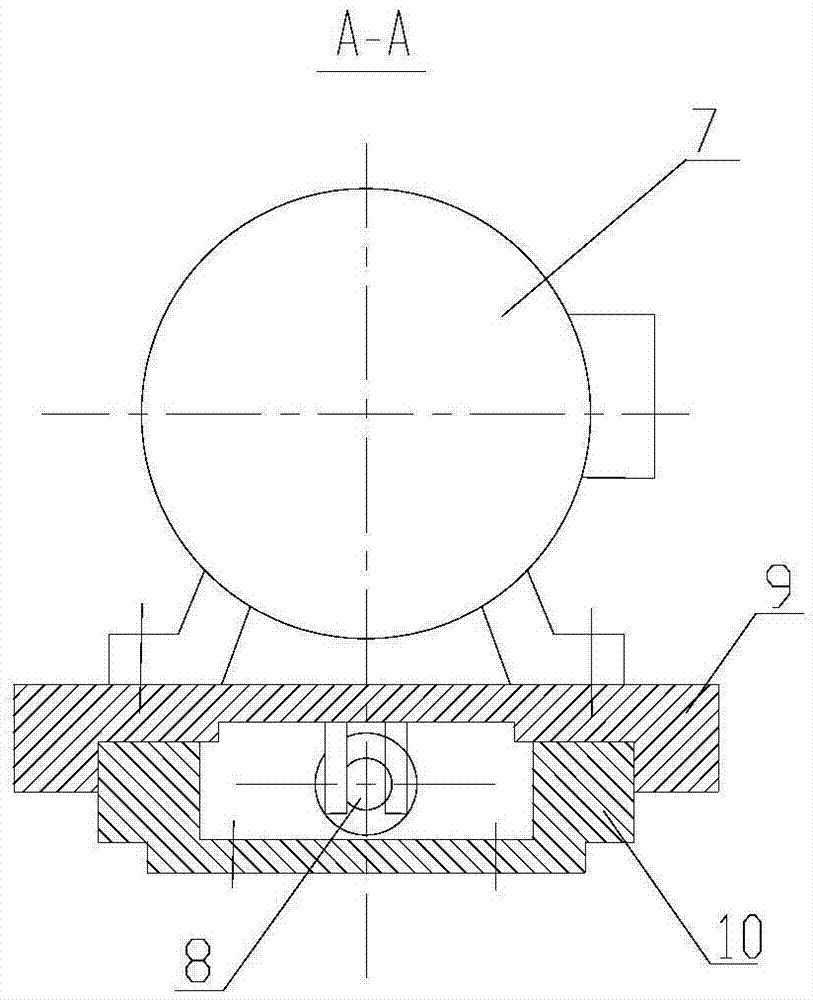

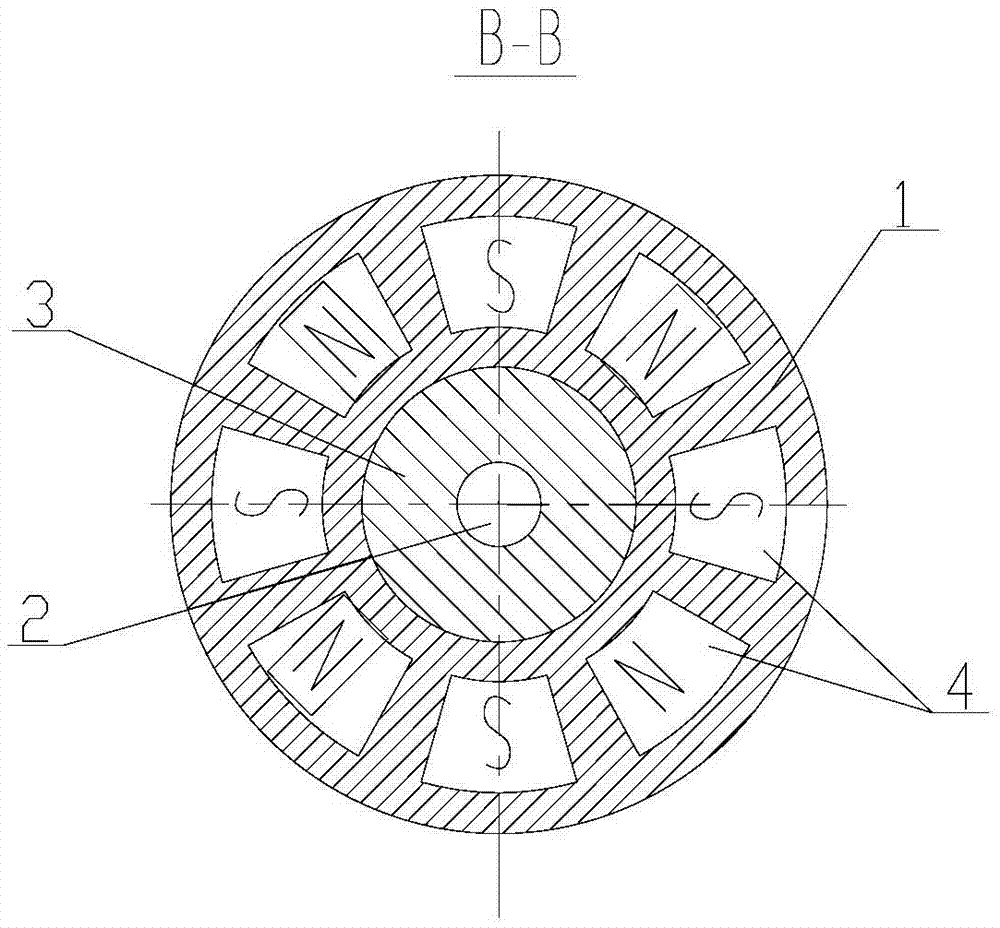

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] See Figure 1-Figure 3 , is a structural schematic diagram of the magnetic sensor device of the present invention, a magnetic transmission device with coupling, clutch and speed regulation functions of the present invention, including a permanent magnet eddy current coupling, an axial gap adjustment device and a control device, the The permanent magnet eddy current coupling consists of a copper disc 5 set on the shaft end of the motor and an aluminum disc 1 set on the load shaft end. The copper disc 5 and the aluminum disc 1 are arranged in parallel with a gap in the middle, and the aluminum disc 1 is equipped with a permanent magnet 4 The axial gap adjustment device is composed of an upper slide table 9, a slide table 10 and an electric / electro-hydraulic push rod 8. The table 10 is connected with the upper slide table 9, and the motor 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com