Flavored beef patty and preparation method thereof

A beef patty and flavor technology, applied in the directions of bacteria, Lactobacillus, food science, etc. used in food preparation, can solve the problems of unclear fermentation microorganisms, easy contamination in the fermentation process, and difficulty in guaranteeing the fermentation flavor, so as to promote dissolution and improve meat quality. Soft and delicate, the effect is conducive to flavor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

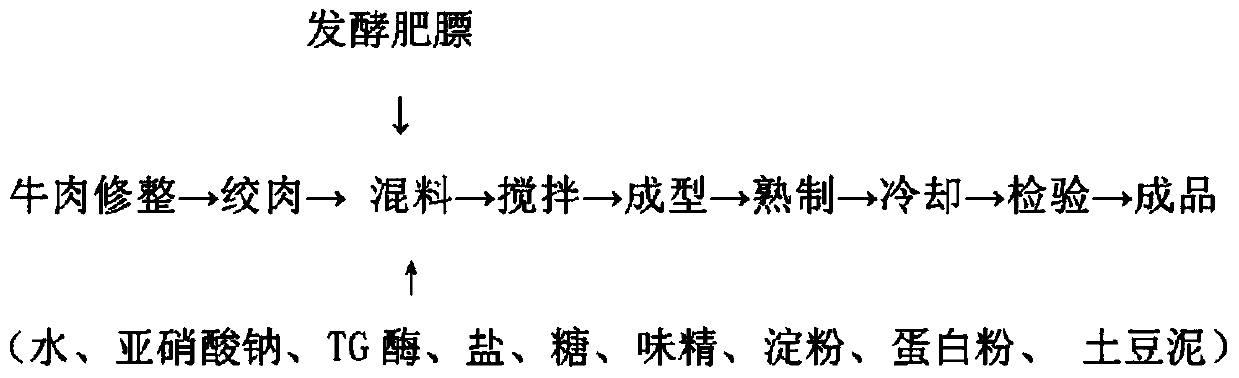

Method used

Image

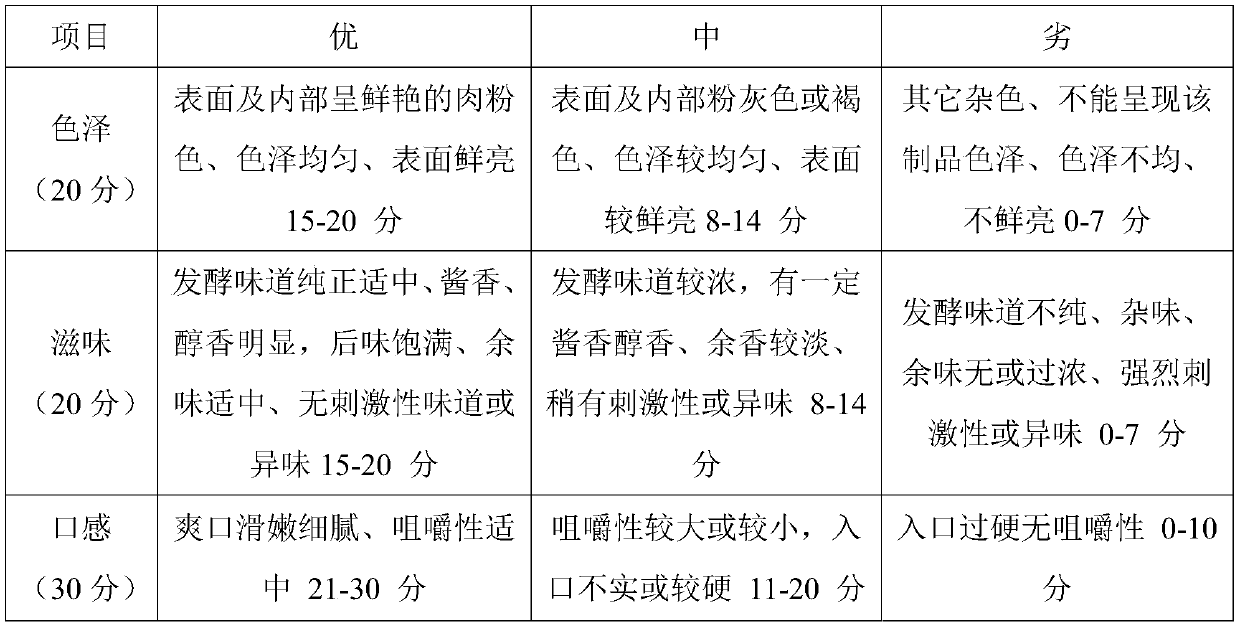

Examples

Embodiment 1

[0037] A kind of fermented fat of the present invention is prepared by the following preparation method:

[0038] (1) Pretreatment: Wash the required knives, pots, chopping boards, beakers and other utensils with boiling water for later use; wash the fat fat to remove blood stains, hair stains and impurities, and then blanch in hot water at 80°C for 30 seconds , take it out and cool it to room temperature; then put it in the freezer at -18°C for 60 minutes to make the fat fat into a slightly frozen state, and cut the fat fat into 0.5cm 3 sized diced particles.

[0039] (2) Take 300 g of the pretreated fat, add 3 ml of white wine (the alcohol content of the white wine is 53 degrees), and mix evenly with 4.80 g of salt to obtain a fermentation substrate.

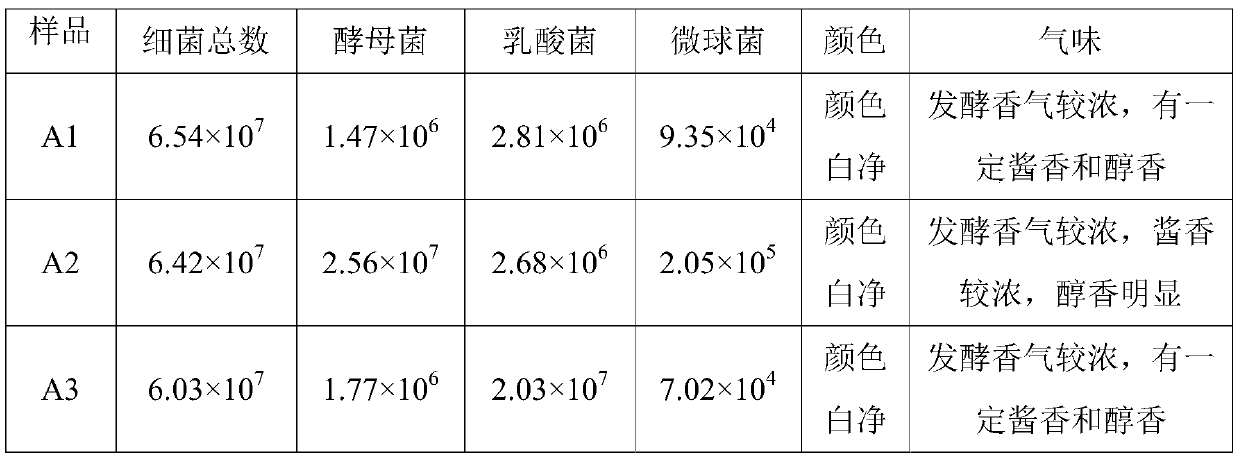

[0040] (3) Divide the above-mentioned fermentation substrate into three parts on average, and inoculate 1 ml of fermentation broth 1, fermentation broth 2, and fermentation broth 3 respectively to obtain a mixture. Fermentat...

Embodiment 2

[0049] A flavor beef cake of the present invention, comprising beef and fermented fat A1, wherein the mass ratio of beef and fermented fat is 8:2; also includes 40wt% of water, 0.01wt% of sodium nitrite, 0.04wt% of TG enzyme, the salt of 1wt%, the sugar of 0.5wt%, the monosodium glutamate of 0.25wt%, the starch of 4wt%, the protein powder of 1wt%, the mashed potato of 4wt% (percent sign represents accounting for the total mass of beef and fermented fat percentage content).

Embodiment 3

[0051] A flavored beef cake of the present invention, comprising beef and fermented fat A1, wherein the mass ratio of beef and fermented fat is 7:3; also includes 40wt% of water, 0.01wt% of sodium nitrite, 0.04wt% of TG enzyme, the salt of 1wt%, the sugar of 0.5wt%, the monosodium glutamate of 0.25wt%, the starch of 4wt%, the protein powder of 1wt%, the mashed potato of 4wt% (percent sign represents accounting for the total mass of beef and fermented fat percentage content).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com