Freeze-dried kelp and chicken soup and preparation method thereof

A production method and kelp technology, applied in the functions of food ingredients, food science, applications, etc., can solve the problems of high food pre-processing requirements, increased economic investment risks, increased process costs, etc., to increase daily activity time and improve physical function. Good, not easy to inactivate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

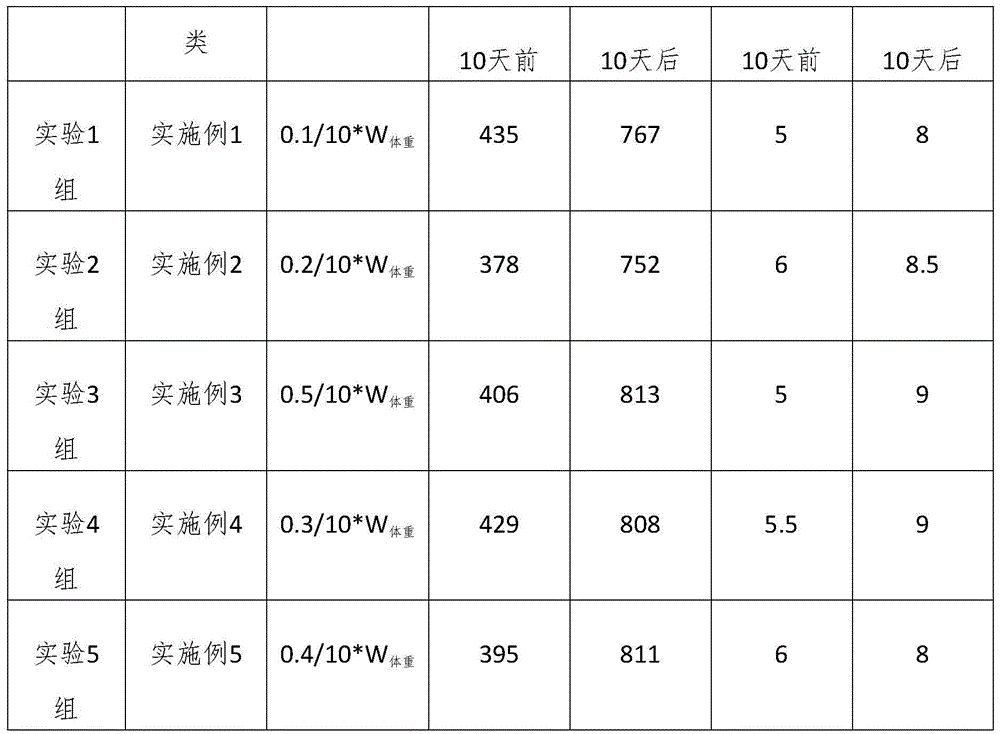

Examples

Embodiment 1

[0032] Step 1: Raw material selection and weighing

[0033] Chicken 50kg, dried kelp 30kg, ginger 3kg, pepper 0.3kg, salt 1.2kg, monosodium glutamate 0.1kg, starch 0.4kg, carrageenan 0.05kg.

[0034] Step 2: Making Chicken Stock

[0035] Cut the native chicken into pieces, put it into 130L of water, boil it for 10 minutes at a temperature of 100°C, then add kelp, ginger, and pepper in turn, and then simmer for 5 hours at a temperature of 90°C to obtain the original chicken soup.

[0036] Step 3: Making Kelp Chicken Soup

[0037] Put the carrageenan into the original chicken soup and stir for 5 minutes, then add the starch and stir evenly, concentrate with high heat at a temperature of 95°C for 30 minutes, then add salt and monosodium glutamate and stir evenly, and separate the solid and liquid to obtain concentrated soup and chicken And kelp-based solids.

[0038] Step 4: Molding Packaging

[0039] Put the separated solid into the mold, then pour the concentrated soup into...

Embodiment 2

[0041] Step 1: Raw material selection and weighing

[0042] Chicken 60kg, dried kelp 36kg, ginger 2.3kg, pepper 0.5kg, salt 1kg, monosodium glutamate 0.1kg, starch 0.3kg, carrageenan 0.03kg.

[0043] Step 2: Making Chicken Stock

[0044] Cut the local chicken into 180L water, boil it at a temperature of 98°C for 20 minutes, then mix the kelp, ginger, and pepper evenly, put it in water, and stew it at a low heat of 80°C for 6 hours to obtain the original chicken soup .

[0045] Step 3: Making Kelp Chicken Soup

[0046] Put starch, carrageenan, salt, and monosodium glutamate into the original chicken soup in sequence. The time interval for adding the materials is 3 minutes. After concentrating for 40 minutes with a high temperature at 95°C, the concentrated soup is obtained through solid-liquid separation and chicken and seaweed. Lord's solid.

[0047] Step 4: Molding Packaging

[0048] Put the separated solid into the mold, then pour the concentrated soup into the mold, so...

Embodiment 3

[0050] Step 1: Raw material selection and weighing

[0051] Chicken 55kg, dry kelp 36kg, ginger 2.7kg, pepper 0.3kg, salt 1.4kg, monosodium glutamate 0.1kg, starch 0.4kg, carrageenan 0.04g.

[0052] Step 2: Making Chicken Stock

[0053] Cut the native chicken into 154L water, boil it at 97°C for 15 minutes, then add ginger, kelp, and pepper in turn, the time interval of adding the materials is 2 minutes, and then stew it at a low heat of 85°C 5.5h, obtain chicken broth.

[0054] Step 3: Making Kelp Chicken Soup

[0055] Put salt, monosodium glutamate, starch, and carrageenan into the original chicken broth at the same time, concentrate for 30 minutes at a temperature of 96°C, and then separate the solid and liquid to obtain the concentrated soup and solids mainly composed of chicken and kelp.

[0056]Step 4: Molding Packaging

[0057] Put the separated solid into the mold, then pour the concentrated soup into the mold, so that the solid-liquid ratio in the mold is 1:4, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com