Horizontal rotary drum grinder and grinding apparatus thereof

The technology of a drum mill and a crushing device, which is applied in the direction of grain processing, etc., can solve the problems of poor crushing effect, high power consumption, and low crushing efficiency, and achieve excellent crushing effect, improved crushing efficiency, and reduced production raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

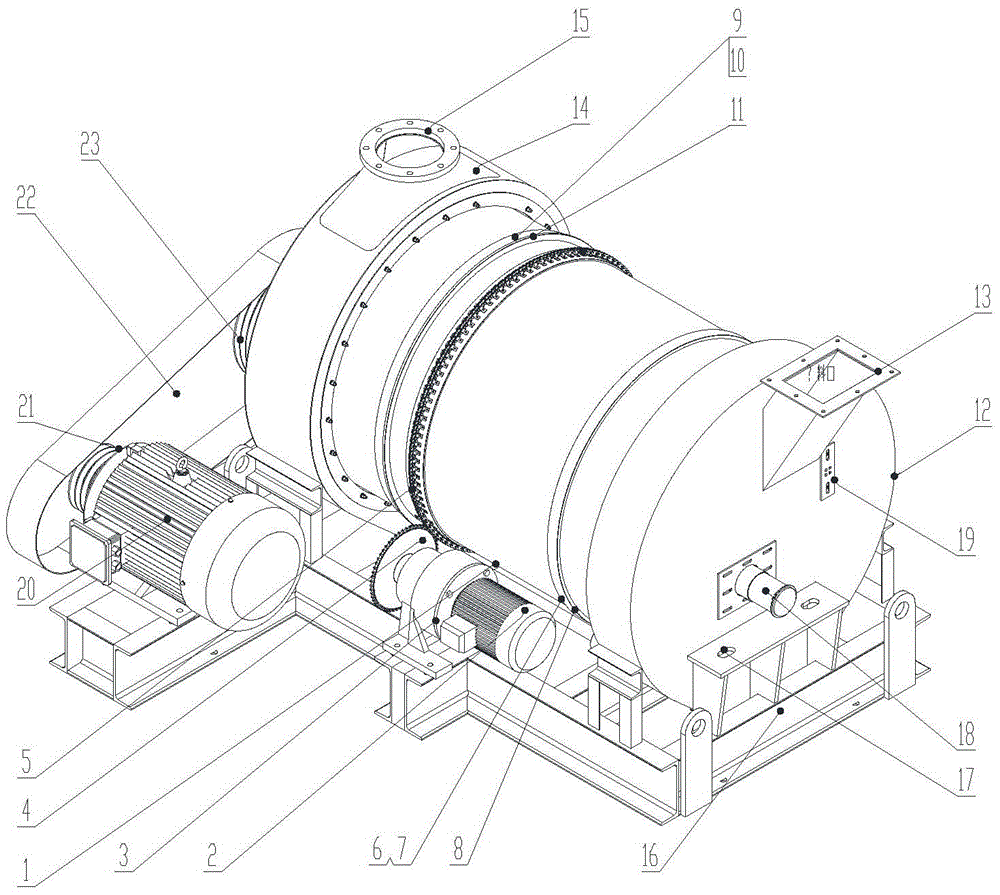

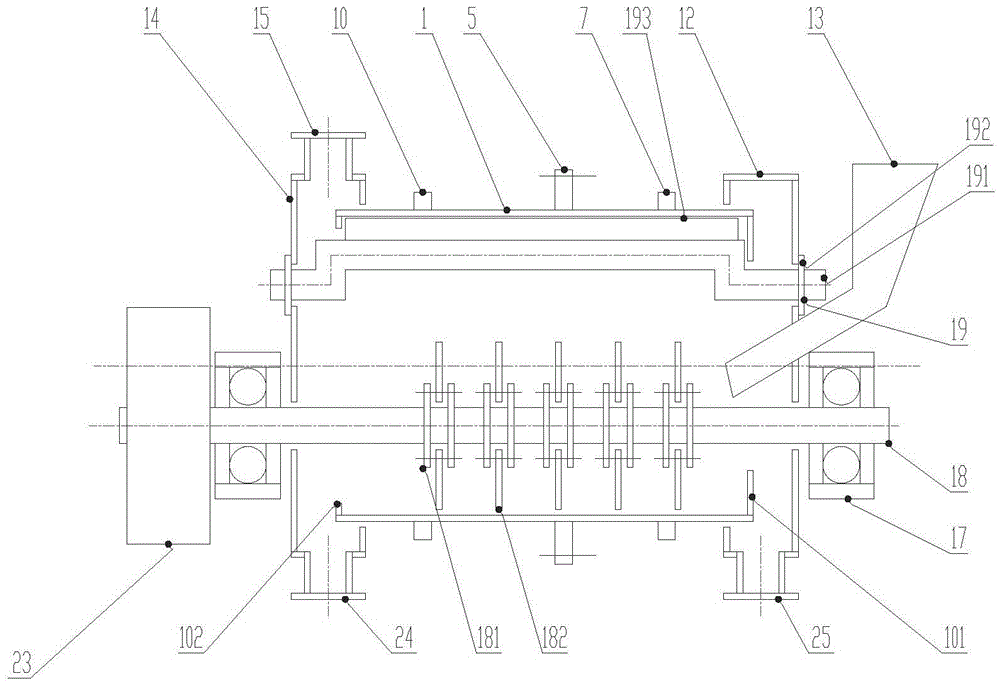

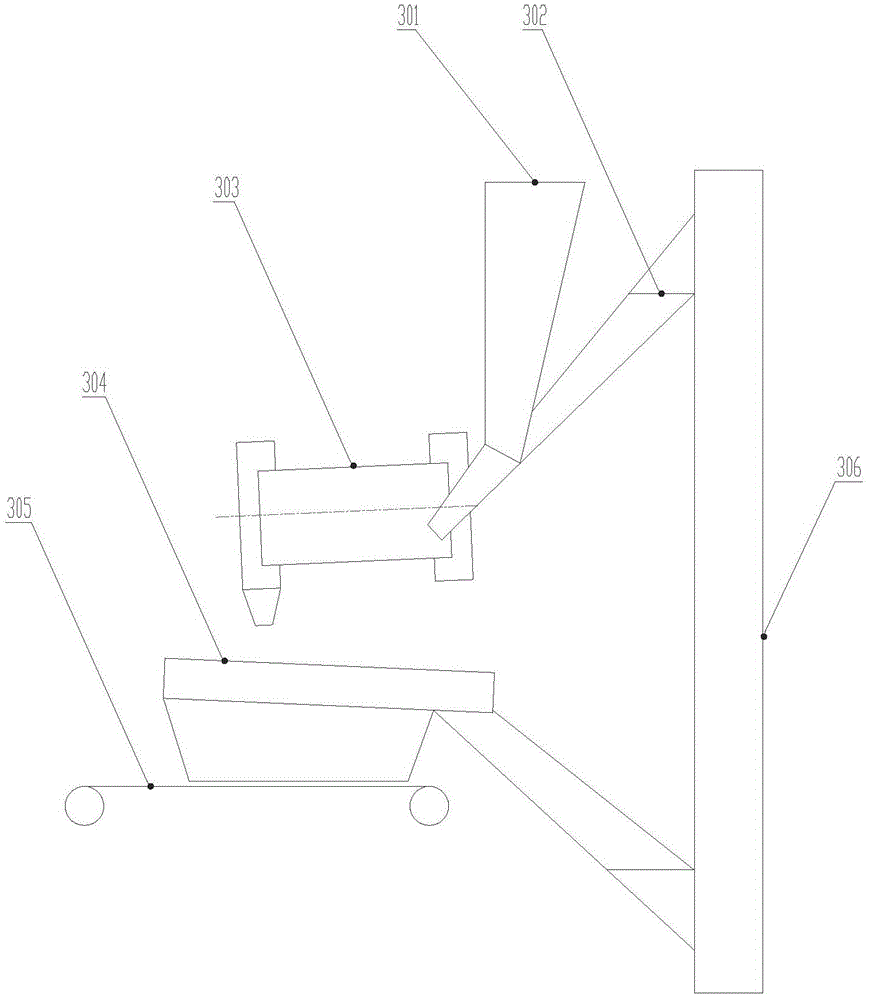

[0034] Such as figure 1 , 2 As a specific embodiment shown, the present invention discloses a horizontal drum mill 303, which consists of four parts: a drum device, a crushing device, a scraper device and a base. The drum device is installed on the base, and the crushing device and the scraper device are installed in the drum unit; if figure 1Shown: the roller device consists of cylinder body 1, front baffle 101, rear baffle 102, feed box 12, discharge box 14, feed pipe 13, air outlet pipe 15, discharge pipe 24, front support roller 6, rear Supporting wheel 9, front rolling ring 7, rear rolling ring 10, front stop wheel 8, rear stop wheel 11, pinion 4, large gear 5, barrel motor 2 and barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com