Laser cutting device

A technology of laser cutting and laser transmitter, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inaccurate cutting of pole pieces, prone to deflection, easy to produce pits, burrs, etc., and achieve production The effect of improving efficiency, improving alignment accuracy, and reducing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below:

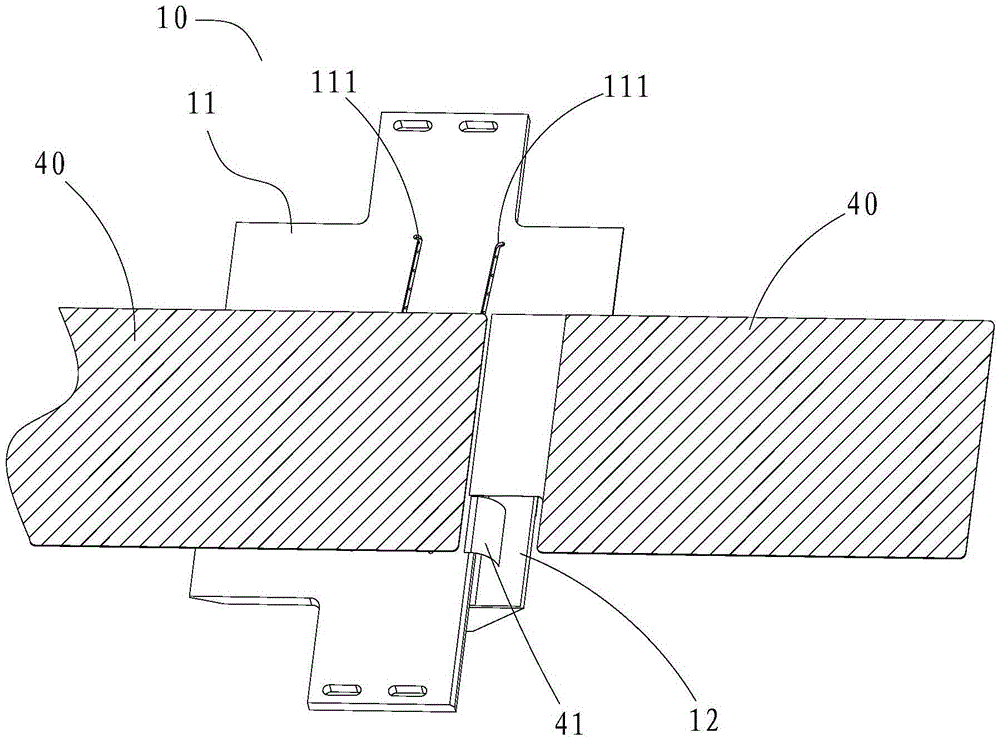

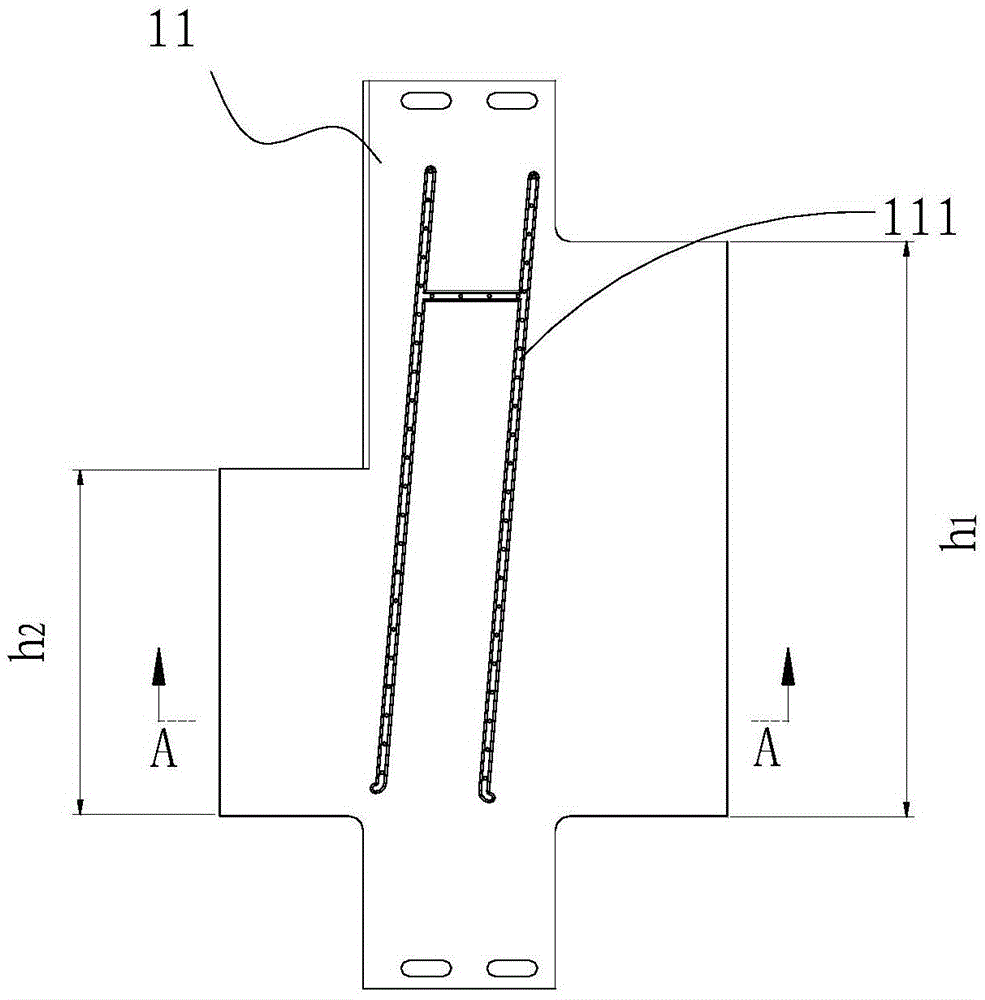

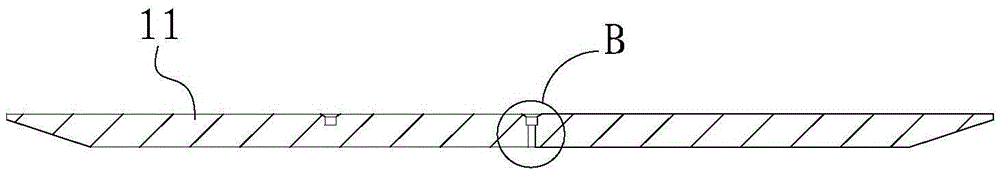

[0033] Such as figure 1As shown, the laser cutting device of the present invention includes a laser cutting mechanism 10 . The laser cutting mechanism 10 includes a support plate 11 for carrying the battery pole piece 40 , and a laser emitter (not shown in the figure) opposite to the support plate 11 . The laser emitter is used for cutting the battery pole piece 40 , and the support plate 11 is provided with a groove 111 on the side opposite to the laser emitter. The main purpose of the groove 111 is to make the support plate 11 avoid the laser beam emitted by the laser emitter, so as to prevent the laser beam from damaging the support plate 11 when cutting the battery pole piece 40 . And the shape of the groove 111 is set according to the cutting shape of the battery pole piece 40, for example, the shape of the groove 111 can be set to H type, T type or W type, which is convenient for the laser tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com