Quick rubber tube locating device

A positioning device and fast technology, applied in metal processing and other directions, can solve the problem of inaccurate cutting position, etc., and achieve the effect of simple operation, simple structure and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

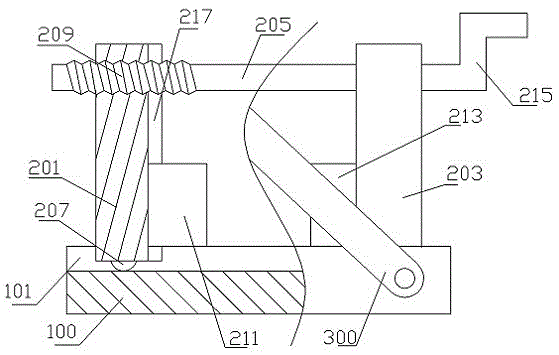

[0014] The reference signs in the accompanying drawings of the description include: machine base 100, chute 101, left slider 201, right slider 203, rotating shaft 205, left pulley 207, left threaded end 209, left clamping block 211, right clamping block 213, handle 215, left chute 217, guillotine 300.

[0015] Such as figure 1 The rubber hose rapid positioning device shown includes a base 100, a guillotine 300 and a positioning mechanism. The base 100 is provided with a chute 101, and the positioning mechanism includes a left slider 201, a right slider 203, a left clamping block 211, and a right clamp. Holding block 213 and rotating shaft 205, the bottom surface of left slide block 201 is provided with left pulley 207, and left pulley 207 offsets with chute 101, and the bottom surface of right slide block 203 is provided with right pulley, and right pulley offsets with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com