Double-horizontal-shaft vibrating and stirring device with main blades and auxiliary blades

A technology of vibrating stirring and auxiliary blades, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of low mixing efficiency, affecting mixing efficiency and mixing uniformity, and incomplete utilization of cement, etc., to achieve Enhanced diffusion and convective kneading, good working reliability, and improved cement utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

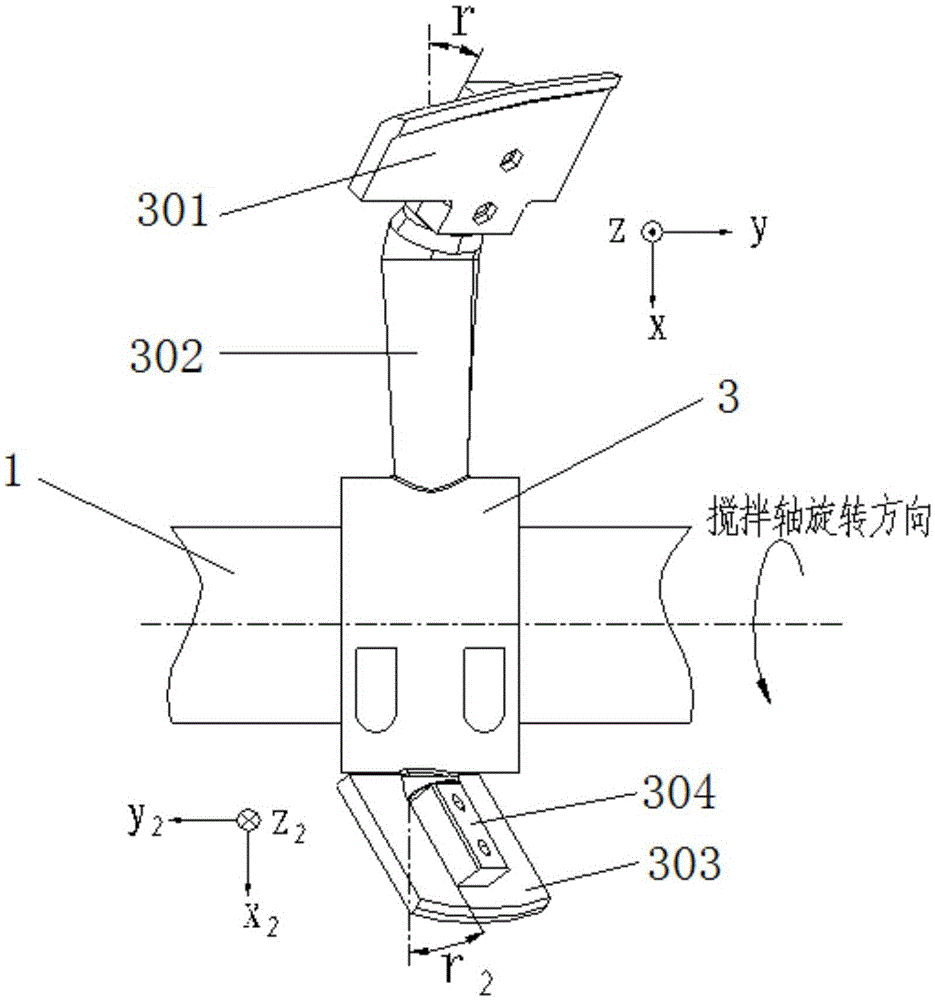

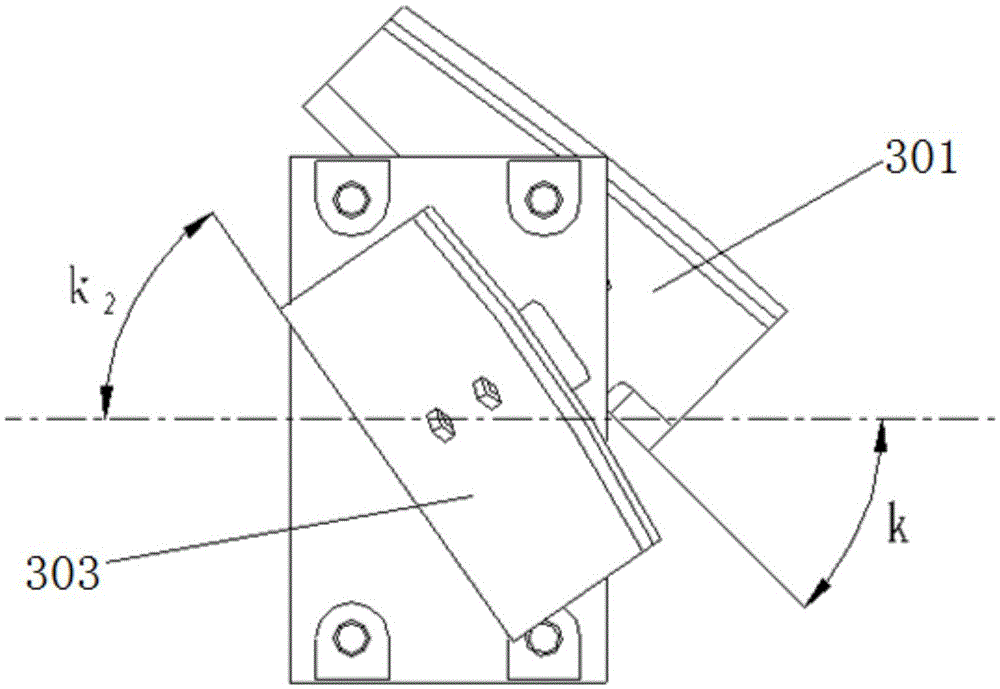

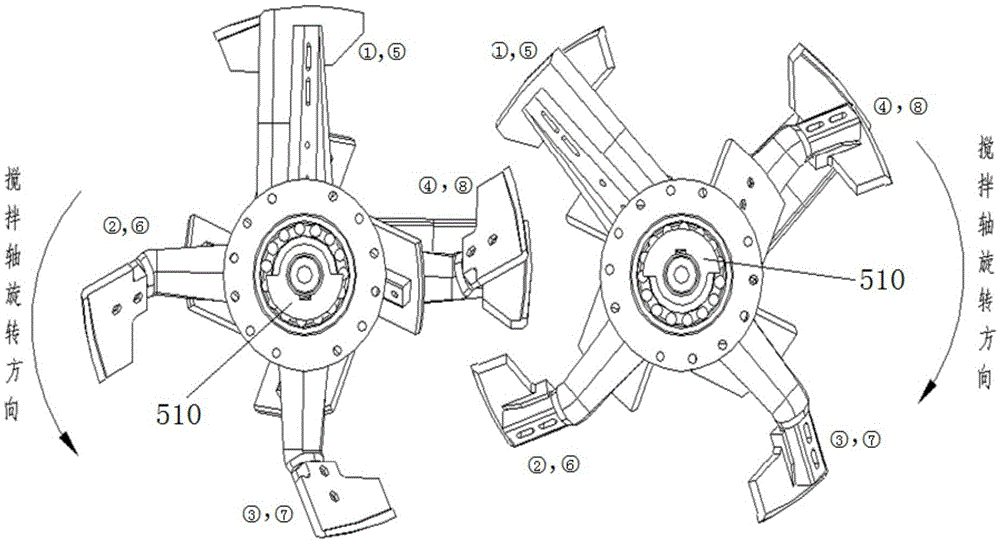

[0037] Comply with the above-mentioned technical scheme, see figure 1, the double-shaft vibrating stirring device with main and auxiliary blades of the present invention includes a stirring drum, and two stirring shafts 1 are arranged in the stirring drum, and a propulsion stirring tool 2, a plurality of main stirring tools 2, and a plurality of main shafts are sequentially arranged on the stirring shaft 1 along the axial direction. Stirring tool 3 and return stirring tool 4, described main stirring tool 3 comprises the main stirring blade 301 that is symmetrically arranged on the stirring shaft 1 and the auxiliary stirring blade 302; 302 is the distance from the stirring shaft 1; during the rotation of the stirring shaft 1, the direction of the axial force and the radial force generated by the main stirring blade 301 and the auxiliary stirring blade 302 on the material are opposite.

[0038] The two stirring shafts 1 of the twin-shaft vibration stirring device of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com