Film cutting device

A cutting device and film technology, applied in thin material handling, transportation and packaging, sending objects, etc., can solve problems such as wasting costs, miscutting, and delaying production efficiency, and achieve the goals of improving production efficiency, saving energy, and increasing yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

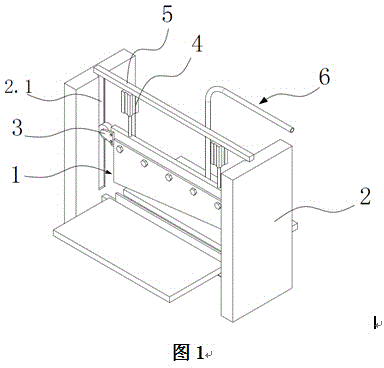

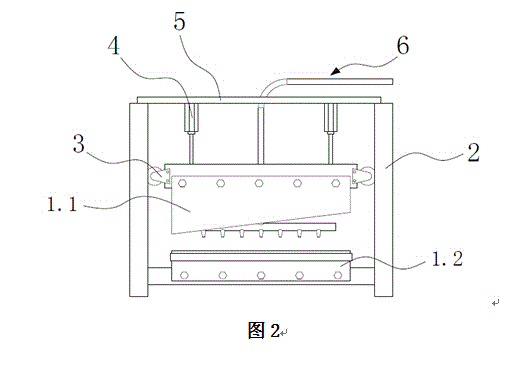

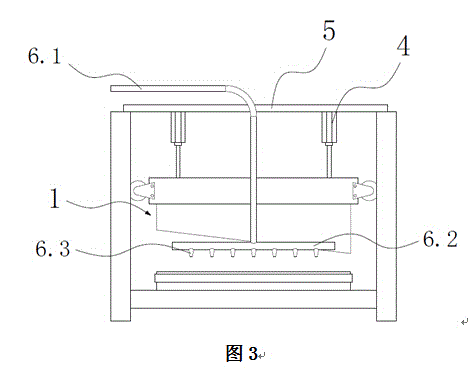

[0010] Such as figure 1 and figure 2 As shown, a film cutting device includes a cutting knife 1 and a wallboard 2, the cutting knife 1 includes an upper knife 1.1 and a lower knife 1.2, the top of the upper knife 1.1 is provided with several cylinders 4, and the cylinders are fixed on the beam 5, the two ends of the upper knife 1.1 are symmetrically provided with a guide wheel 3, and the wallboard is provided with a guide groove 2.1, and the guide wheel 3 cooperates with the guide groove 2.1, as image 3 As shown, the blowing device 6 is provided behind the cutting knife 1, and the blowing device 6 includes a blowing pipe 6.1 and a horizontal pipe 6.2, and one end of the conduit communicates with the middle part of the horizontal pipe 6.2. The bottom of the horizontal tube 6.2 is provided with several blowing heads 6.3. The horizontal pipe 6.2 also can directly have blowing holes below, and the technical effect is the same.

[0011] During use, the continuous film is pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com