A kind of preparation method of fodosteine

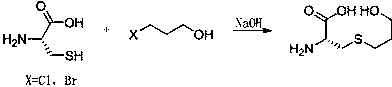

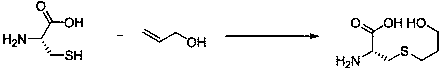

A technology of fudosteine and cysteine, which is applied in the field of medicine, can solve the problems of short reaction time, low purity, and easy residual heavy metals, and achieve the effects of mild reaction conditions, simple process, and high atom utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] At room temperature, dissolve 20 g of L-cysteine in 200 mL of water, add 7.2 g of sodium hydroxide, stir for 1 hour, cool to 0-10°C, and add 12.5 g of oxetane dropwise to the reaction system After dripping and raising to room temperature and stirring for 2 hours, heating to 40-50°C and stirring for 6 hours, cooling to room temperature, adjusting pH to 6 with 6mol / L hydrochloric acid, distillation under reduced pressure to 1 / 10 of the original volume, and heating to 80°C Hot filter, slowly add 600mL of 95% ethanol to the filtrate, after the addition, cool to 0-10℃ and stir for 2 hours, filter, rinse the filter cake with 30mL of ethanol, and dry with air blow at 40-50℃ to obtain 29.0g of crude product. Add the obtained crude product to a 1000ml four-necked flask, add 570mL of 20% ethanol aqueous solution, heat up to 50-60℃, and after all is dissolved, gradually reduce the temperature to room temperature and stir for 1h, reduce the temperature to 0-10℃, stir for 2h, filter...

Embodiment 2

[0023] At room temperature, dissolve 20 g of L-cysteine in 200 mL of water, add 4.0 g of sodium hydroxide, stir for 1 hour, cool to 0-10°C, and add 19.2 g of oxetane dropwise to the reaction system After dripping, raise to room temperature and stir for 2 hours, warm to 40-50°C and stir for 8 hours, cool to room temperature, adjust pH to 6 with 6mol / L hydrochloric acid, distill under reduced pressure to 1 / 10 of the original volume, and warm to 80°C Hot filter, slowly add 600mL of 95% ethanol to the filtrate, after the addition, cool to 0-10℃ and stir for 2 hours, filter, rinse the filter cake with 30mL of ethanol, and dry with air at 40-50℃ to obtain 27.9g of crude product. Add the obtained crude product to a 1000ml four-necked flask, add 550mL of 15% ethanol aqueous solution, heat up to 50-60℃, and after all is dissolved, gradually reduce the temperature to room temperature and stir for 1h, reduce the temperature to 0-10℃, stir for 2h, filter, 40 Air-dried at -50°C to constan...

Embodiment 3

[0025] At room temperature, dissolve 20g of L-cysteine in 100mL of water, add 9.0g of sodium hydroxide, stir for 1 hour, cool to 0-10°C, and add 10.5g of oxetane dropwise to the reaction system After dripping and raising to room temperature and stirring for 2 hours, heating to 40-50°C and stirring for 5 hours, cooling to room temperature, adjusting pH to 6 with 6mol / L hydrochloric acid, distillation under reduced pressure to 1 / 6 of the original volume, and heating to 85°C Hot filter, slowly add 300mL 95% ethanol to the filtrate, cool to 0-10°C and stir for 2 hours after addition, filter, rinse the filter cake with 30mL ethanol, and dry with air blow at 40-50°C to obtain 28.4g crude product. Add the obtained crude product to a 1000ml four-necked flask, add 560mL 30% ethanol aqueous solution, heat up to 50-60℃, and after all is dissolved, gradually reduce the temperature to room temperature and stir for 1h, reduce the temperature to 0-10℃, stir for 2h, filter, 40 Air-dried at -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com