Lashing devices for scaffolding slabs

A technique for scaffolding and fixing substrates, which is applied in the connection of scaffolding, building structure support, building structure support, etc. It can solve the problems that iron wires cannot be reused, the iron wire binding process is cumbersome, and the binding efficiency is low, so as to facilitate climbing operations and reduce Potential safety hazards and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

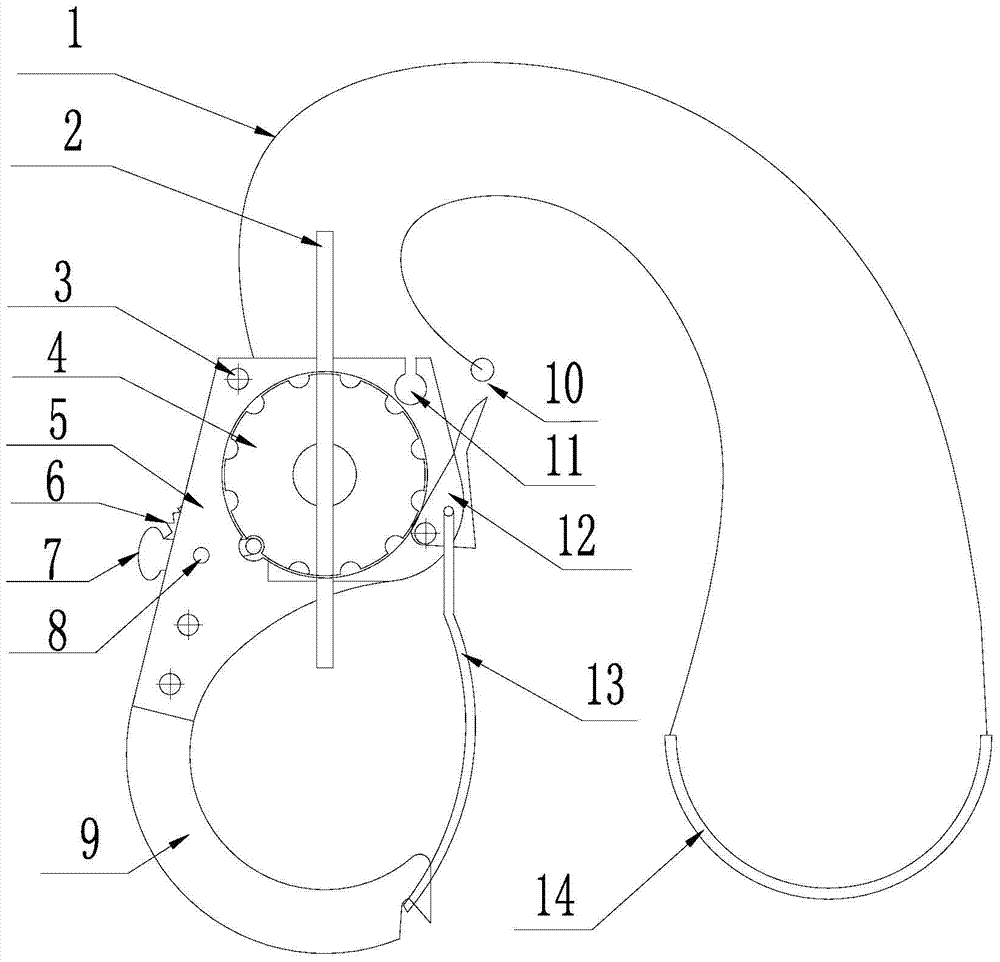

[0011] Such as figure 1 As shown, the present invention provides a binding device for scaffold boards, including a fixed base plate 5, on which a hook-shaped steel pipe clasp 9 and a locking handle 12 are respectively installed, and a locker 13 is also included. One end of the locking device 13 is installed on the locking handle 12 and the other end is detachably installed on the steel pipe snap ring 9; on the fixed base plate 5, a rotating ratchet 4 is rotatably installed through a rotating shaft, and the rotating ratchet 4 One end of the steel wire rope 1 is wound on the top, and the other end of the steel wire rope 1 is connected with a cylindrical block 10, and a cylindrical card slot 11 matched with the cylindrical block 10 is opened on the fixed base plate 5. A ratchet block 7 is also installed on the fixed base plate 5 next to the ratchet 4 .

[0012] Wherein the steel wire rope 1 is sleeved with a section of arc-shaped hollow tube 14 .

[0013] It also includes a blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com