Oil pump connecting support

A technology for connecting brackets and oil pumps, applied to shock absorbers, engine components, machines/engines, etc., can solve problems such as structural damage and fracture, achieve the effects of reducing weight, reducing manufacturing thickness, and preventing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

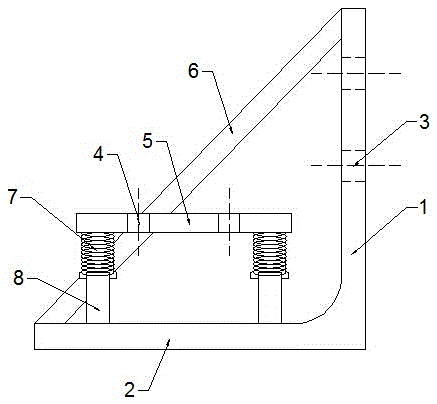

[0014] like figure 1 As shown, the invention discloses an oil pump connecting bracket, which includes a bracket body connected to the machine body and a shock absorbing device arranged on the bracket body.

[0015] The bracket body is L-shaped, including a connecting plate 1 vertically arranged and connected to the body, and a mounting plate 2 arranged perpendicular to the connecting plate 1; the connection between the mounting plate 2 and the connecting plate 1 has a circular arc chamfer , the connecting plate 1 is provided with several threaded through holes A3 for bolts to be inserted and fixed; a pair of reinforcing ribs 6 are also arranged at both ends of the inside of the bracket body along the long axis direction, one side of the reinforcing ribs 6 is fixed on the upper end of the connecting plate 1, and the other is fixed on the upper end of the connecting plate 1. The side is fixed on the outermost end of the mounting plate 2.

[0016] The damping device comprises so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com