Ultralow-temperature vacuum draught fan

An ultra-low temperature, vacuum technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem of not being able to meet the requirements, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

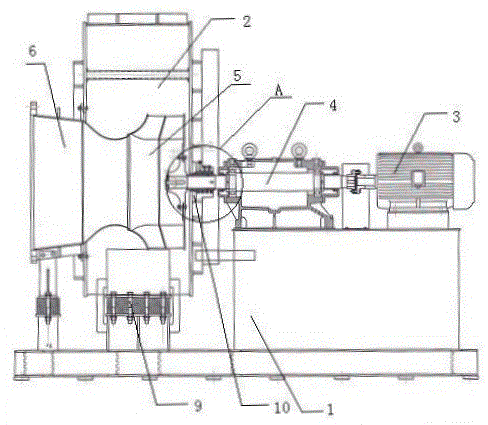

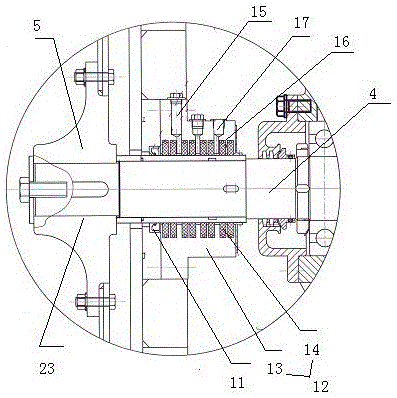

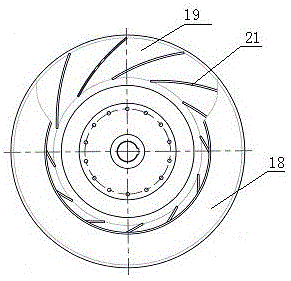

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] As shown in the figure, an ultra-low temperature vacuum fan includes a machine base 1, a casing 2, a motor 3, a main shaft 4, an impeller assembly 5 and an air inlet ring 6, and the outside of the casing 2 is provided with a reinforcing rib group 7, and the reinforcement The rib group 7 is composed of several rings of reinforcing ribs 8, the casing 2 is fixed above the base 1, and a cold bridge 9 is provided between the casing 2 and the base 1, and the cold bridge 9 is made of polytetrafluoroethylene Prepared, the impeller assembly 5 is fixed in the casing 2, one end of the impeller assembly 5 is connected to the air inlet ring 6, and the other end is connected to the motor 3 through the main shaft 4, and the motor 3 is fixed on the base 1, The main shaft 4 passes through the casing 2, the main shaft 4 is made of 16Mn, and a sealing structure 10 is provided betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com