Spiral feeding machine for disposing entangled rubbish

A screw feeder, garbage technology, applied in the direction of combustion method, combustion type, incinerator, etc., to achieve the effect of avoiding economic loss, avoiding odor overflow, and avoiding cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

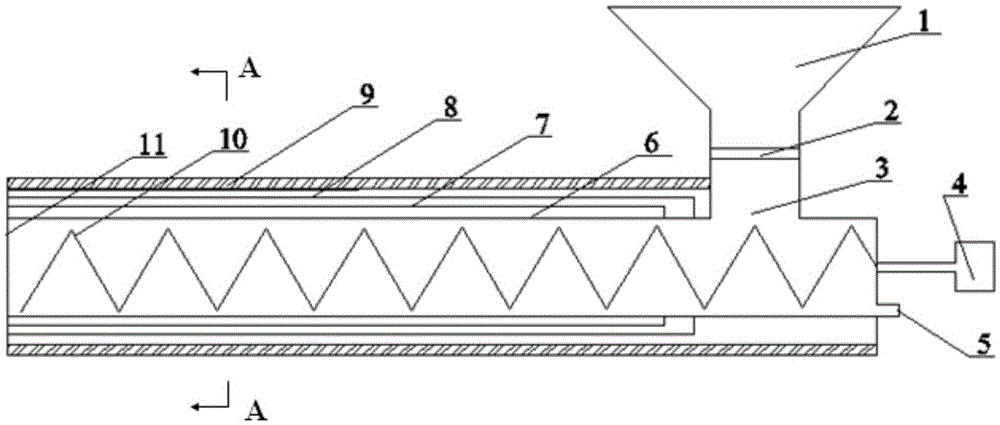

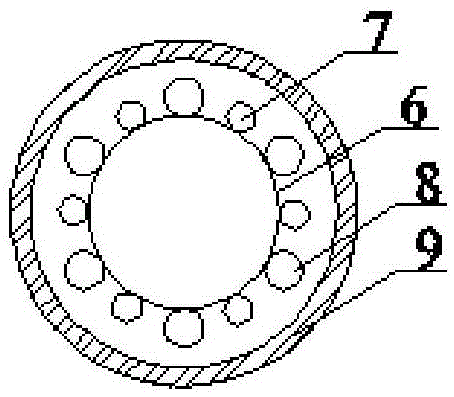

[0035] Preferably, the heating device is an electric heating tube 7, and the electric heating tube 7 is arranged along the outer wall of the cylindrical shell 6 or is arranged in the rotating shaft of the shafted helical blade, such as figure 1 As shown, the electric heating tube 7 is a tubular electric heating element, and when the spiral blade 10 is a shaftless spiral blade, the electric heating tube 7 is arranged on the outer wall of the cylindrical shell 6, and the insulation layer 9 is arranged outside the electric heating tube 7, so as to facilitate The surface of the cylindrical shell 6 is heated to indirectly heat the garbage in the screw feeder; when the screw blade 10 is a screw blade with a shaft, the electric heating tube 7 is arranged in the cavity in the rotating shaft of the screw blade 10 , the insulating layer 9 and the outer wall of the cylindrical housing 6 are arranged in close contact with each other so as to heat the garbage in the screw feeder.

[0036] ...

Embodiment 2

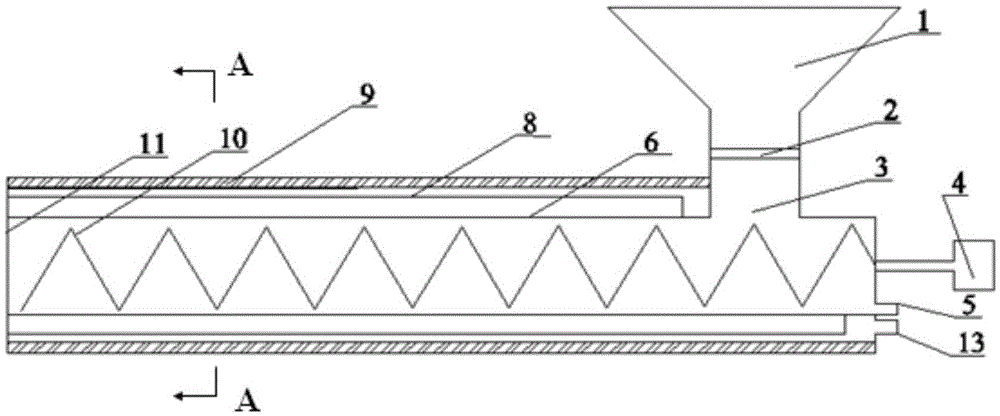

[0038] The difference between embodiment two and embodiment one is that the combustion heating device is arranged on the cylindrical housing 6 or in the rotating shaft of the spiral blade 10, when the combustion heating device is arranged on the cylindrical housing 6, the combustion heating device consists of The burner 12, the annular cavity between the cylindrical shell 6 and the insulation layer 9, and the flue gas outlet 13 arranged at the end of the annular cavity; when the combustion heating device is arranged in the rotating shaft of the spiral blade 10, the combustion The heating device is composed of a burner 12, a cavity in the rotating shaft and a flue gas outlet 13 arranged at the end of the cylindrical shell 6. The burner 12 can be arranged in the annular cavity, and also can be arranged in the rotating shaft of the shafted helical blade, wherein the burner 12 is preferably a gas burner, such as image 3As shown, the gas burner generally adopts an annular tubular ...

Embodiment 3

[0041] The difference between the third embodiment and the second embodiment is that the heating medium device is composed of a medium inlet, a medium channel 14 and a medium outlet, and the medium heating device is arranged on the cylindrical shell 6 or in the rotating shaft of the helical blade 10 . Such as Figure 5 As shown, the medium passage 14 is arranged in the annular cavity, and the hot air flow is passed into the medium passage 14. The hot air flow is preferably the hot flue gas in the incinerator, and the two ends of the medium passage 14 are respectively provided with a medium inlet and a medium outlet. The medium channel 14 can be arranged in the annular cavity, and can also be arranged in the cavity in the rotating shaft of the screw blade 10, then, the position of the insulation layer 9 is correspondingly arranged outside the annular cavity or on the outer wall of the cylindrical housing 6 , this design is to facilitate the hot air flow in the medium channel 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com