Universal aluminum section vehicle end fixing device

A technology of fixing devices and aluminum profiles, which is applied in the direction of railway vehicle testing, etc., can solve problems such as inability to connect, poor versatility, and insufficient theoretical knowledge, and meet the requirements of test stiffness, easy storage and handling, and flexible assembly and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

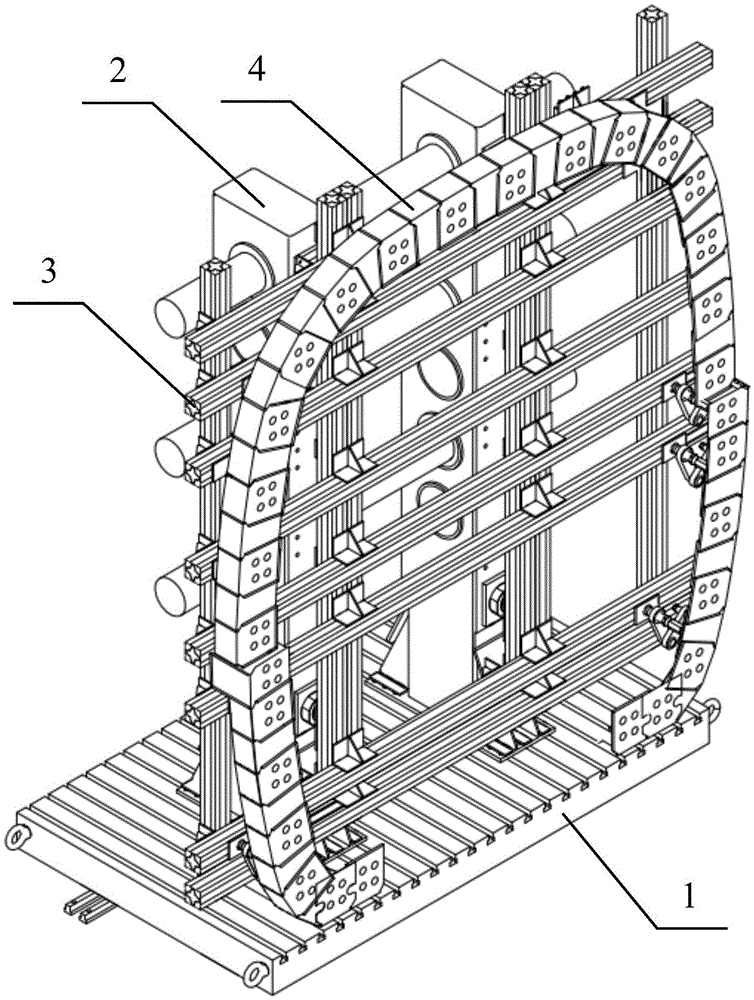

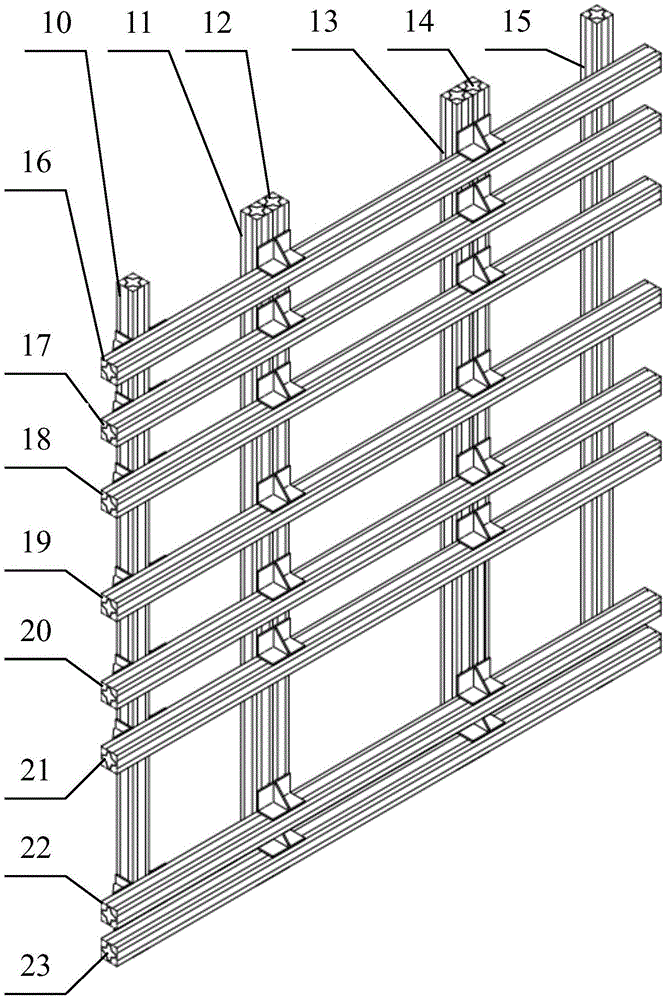

[0026] refer to figure 1 The present invention provides an end wall fixing device for a rail vehicle vehicle-end relationship test, thereby filling the blank of the current rail vehicle vehicle-end relationship test, and meeting the needs of the relevant test for the vehicle-end relationship during rail vehicle operation. The flexible universal supporting end wall assembly composed of the industrial aluminum profile beam combination contained in the universal aluminum profile vehicle end fixing device is the main end wall fixing device of the present invention. It cooperates with the vehicle end wall to connect the arm assembly. The number and installation positions of the edge unit assembly and the test sensors can meet the requirements of different types of rail train car-end relationship tests, and have strong versatility and high structural strength.

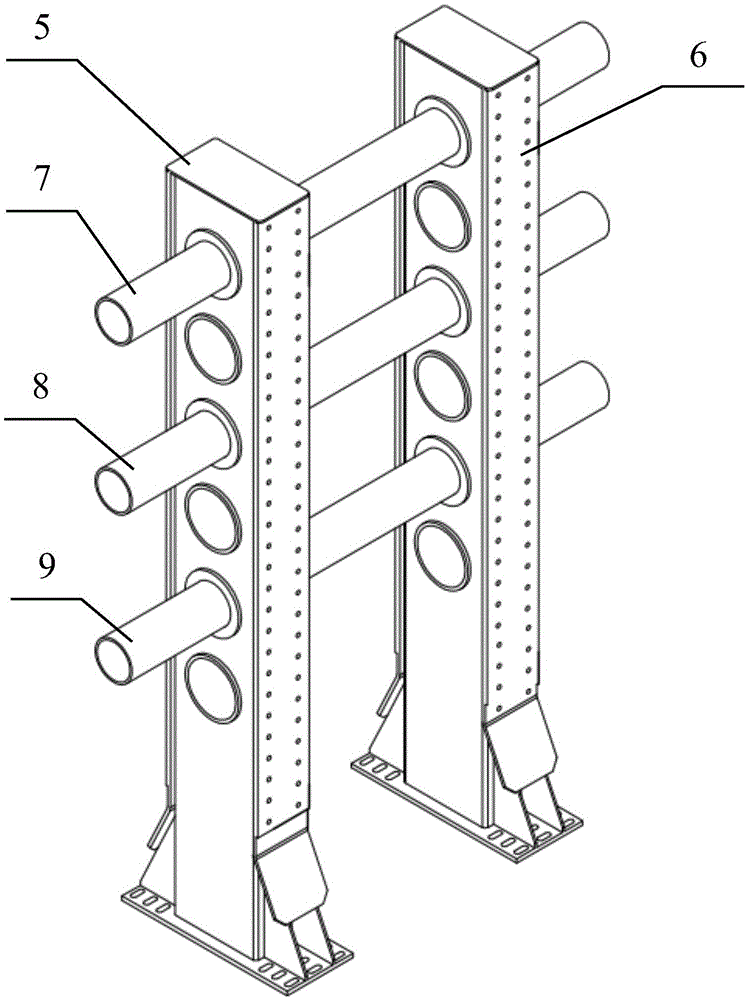

[0027] The device includes a cast iron T-shaped slot base platform 1 , a vehicle end supporting reaction force frame assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com