Cylindrical lithium battery cap

A lithium battery, cylindrical technology, applied in the field of cylindrical lithium battery caps, can solve problems such as affecting the quality of the cap, inability to turn over, performance differences, etc., and achieve the effects of ensuring stability and safety performance, simple structure, and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

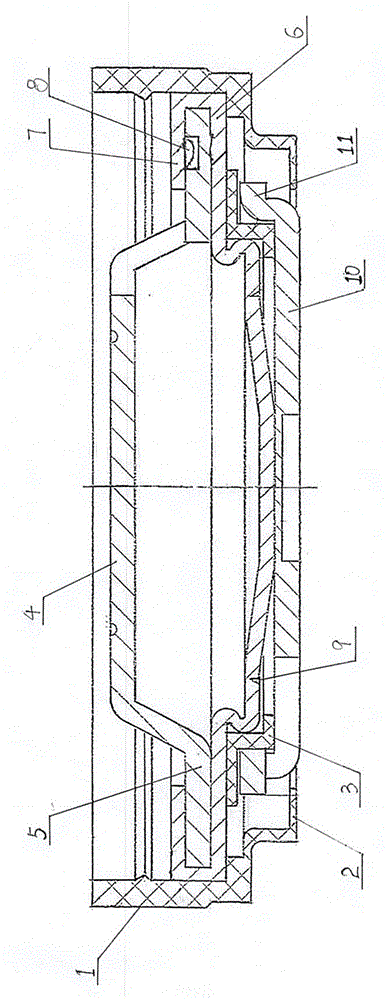

[0012] Further description will be made below in conjunction with drawings and embodiments.

[0013] figure 1 As shown: a cylindrical lithium battery cap includes a sealed outer ring 1, an upper cover 4, an explosion-proof diaphragm 6 and an orifice plate 10. The cross-section of the circumferential convex bending part of the structure is "S" shape, and the bottom surface of the explosion-proof diaphragm 6 in the circular convex structure is provided with a ring of pressure relief grooves 9, and the explosion-proof diaphragm 6 is surrounded by bending areas 7 Inward bending is welded to the upper cover annular area 5 on the four sides of the upper cover 4 through solder joints 8, and the upper edge of the sealed outer ring is bent inward to compress the bending area of the explosion-proof diaphragm. The lower bottom of the sealed outer ring 1 is hollowed out and connected with a circle of coaxial inner and outer support platforms 3, 2. The "S"-shaped bend of the circular co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com