Power tunnel inspection robot lithium battery fast charging management system and method

An inspection robot and fast charging technology, which is applied in the direction of battery circuit devices, current collectors, battery data exchange, etc., can solve the problems that affect the timeliness of robot inspection, long charging time, and high cost, and meet the needs of real-time inspection, The effect of short charging time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

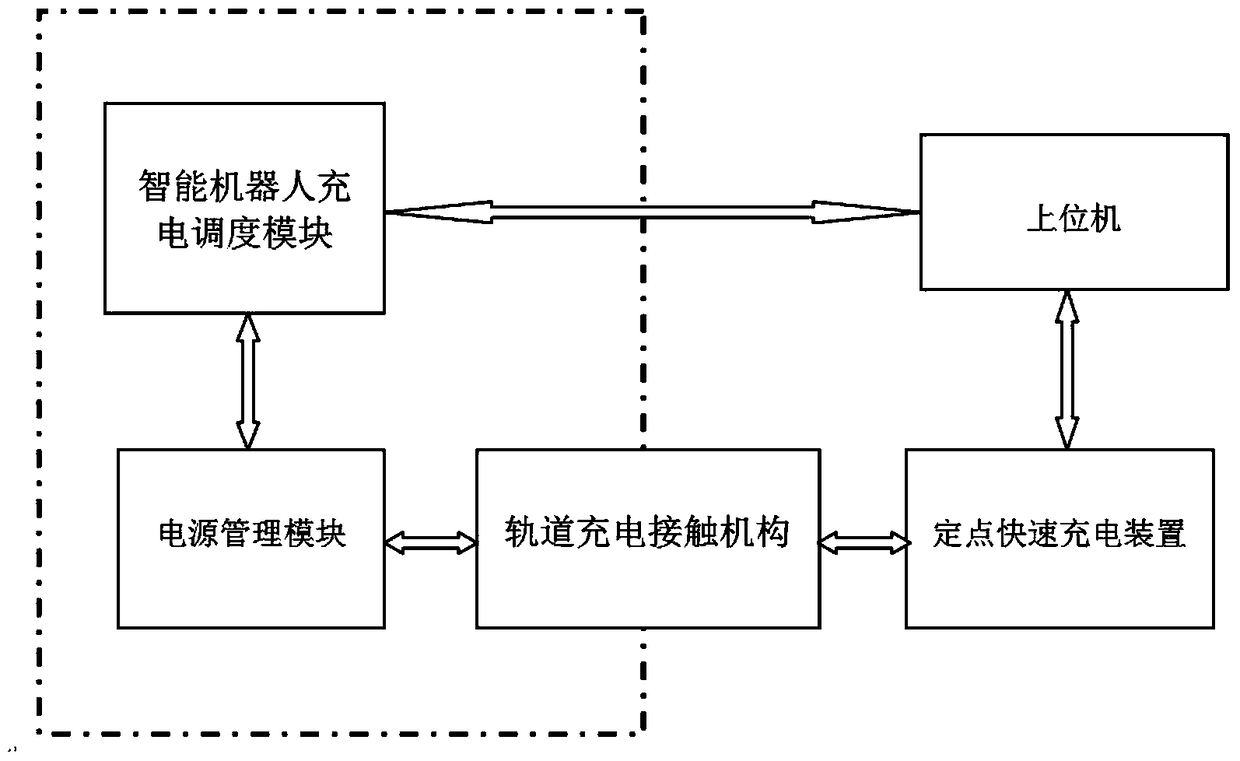

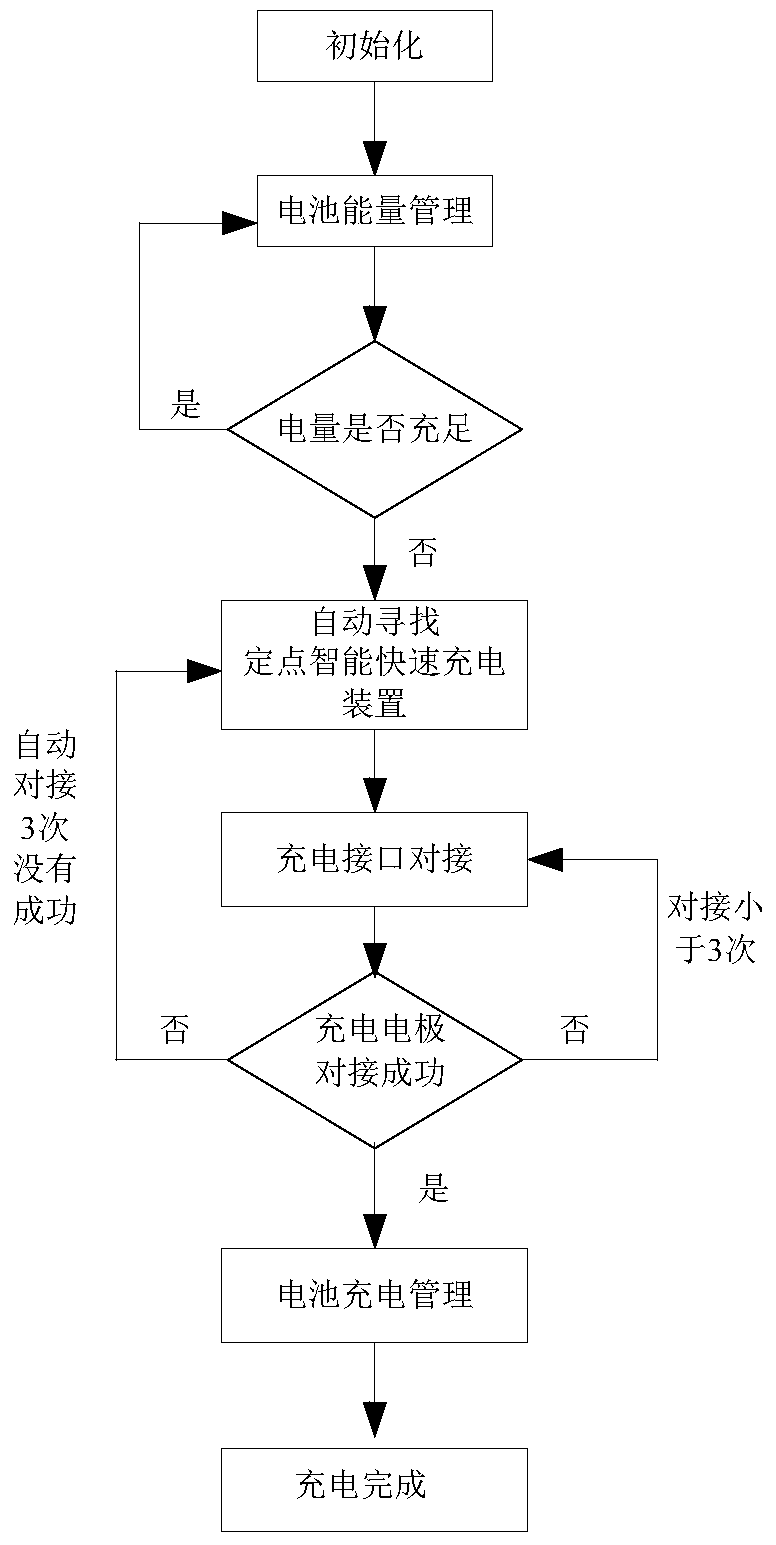

[0050] Such as figure 1 As shown, a power tunnel inspection robot large-capacity lithium battery fast charging management system includes a host computer, an intelligent robot charging scheduling module, a battery management module, a track charging contact mechanism, and a fixed-point intelligent fast charging device.

[0051] The upper computer performs real-time information interaction with multiple fixed-point intelligent fast charging devices distributed in the tunnel through the EtherNet network. At the same time, the host computer communicates with the robot running in the tunnel in real time through the EtherNet network.

[0052] The upper computer can obtain the internal temperature and humidity environment and working status of all fixed-point intelligent fast charging devices in real time, count which charging fixed-point intelligent fast cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com