Flexible and hard combined circuit board and manufacturing method thereof

A soft-rigid combination and production method technology, which is applied in the directions of printed circuit components, structural connection of printed circuits, and assembly of printed circuits with electrical components, which can solve problems such as unfavorable soft-rigid combination circuit boards. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

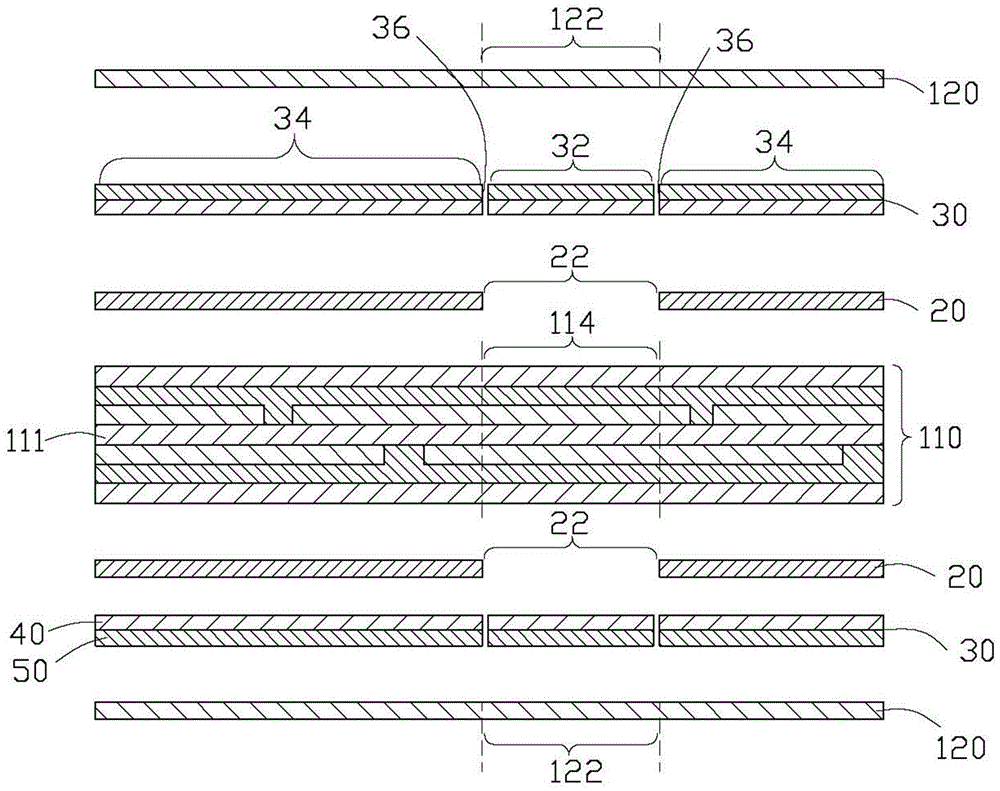

[0020] The manufacturing method of the soft-rigid circuit board provided by the technical solution includes the following steps:

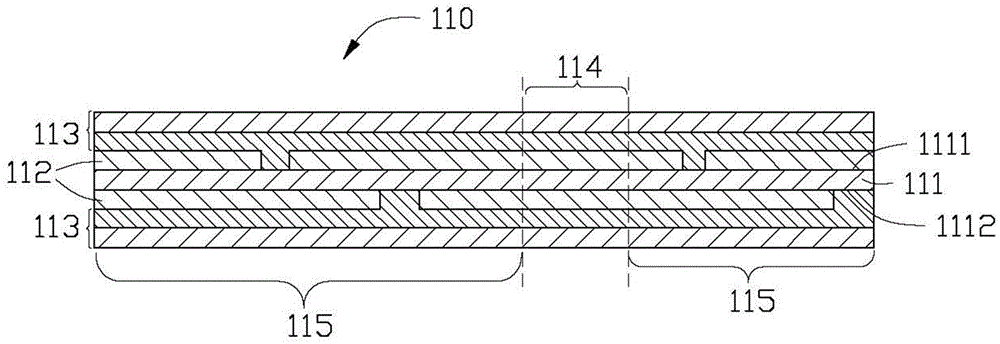

[0021] For a first step, see figure 1 , providing a flexible circuit board 110 .

[0022] The flexible circuit board 110 can be a single-sided circuit board or a double-sided circuit board. In this embodiment, the flexible printed circuit board 110 is taken as an example for illustration. The flexible circuit board 110 includes an insulating layer 111 , first conductive circuit layers 112 formed on opposite sides of the insulating layer 111 , and first covering films 113 respectively formed on surfaces of the two first conductive circuit layers 112 . The flexible circuit board 110 includes a flexible area 114 and a fixing area 115 connected to opposite sides of the flexible area 114 . The flexible area 114 corresponds to the bending area forming the rigid-flex circuit board. The first conductive circuit layer 112 is both distributed in the flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com