Mobile phone and manufacturing method thereof

A manufacturing method and mobile phone technology, applied in the communication field, can solve the problems of unsatisfactory heat dissipation, poor heat dissipation performance of mobile phones, power consumption of mobile phones, etc., and achieve the effect of ultra-thin mobile phone design, affordable price, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

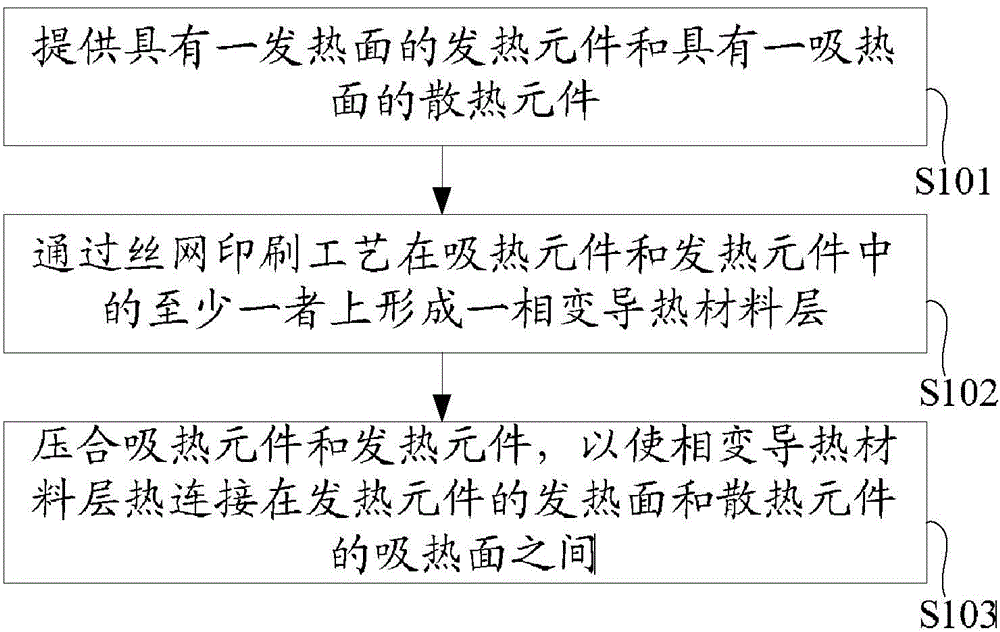

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

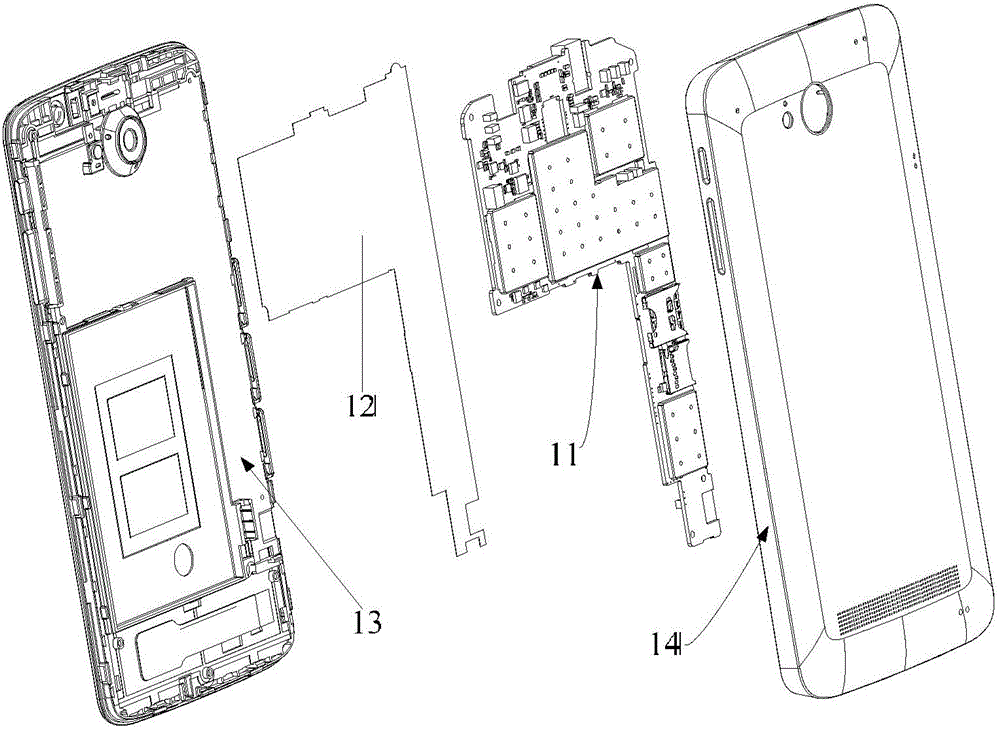

[0026] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the mobile phone of the present invention, which includes a heating element 11 with a heating surface, a heat dissipation element 13 with a heat absorption surface, a phase-change heat-conducting material layer 12 and a mobile phone casing 14. The heating element 11 , the heat dissipation element 13 and the phase-change heat-conducting material layer 12 are arranged on the casing 14 of the mobile phone. The phase-change heat-conducting material layer 12 is thermally connected between the heating surface of the heating element 11 and the heat-absorbing surface of the heat-dissipating element 13 . In this embodiment, the heating element 11 is preferably a PCB assembly, a camera or a liquid crystal display inside a mobile phone, and the heat dissipation element 13 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com