Rice cake hammering machine for mortar

A technology for rice cakes and electric motors, which is applied in the field of mortar-beating rice cake machines, can solve the problems of insufficient punching force of dough, splitting of rice cakes, slow processing speed, etc., and achieves the effect of reducing labor input, maintaining uniform force and strong beating force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

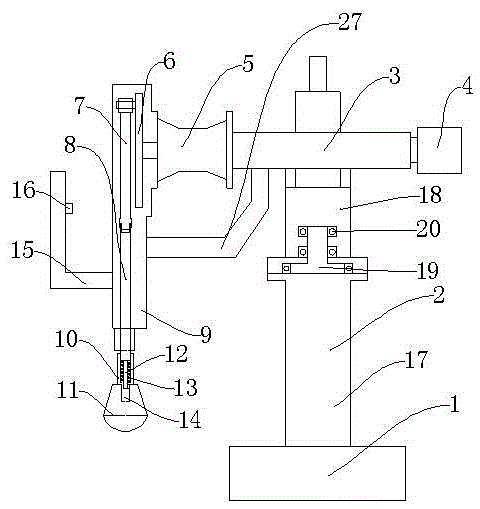

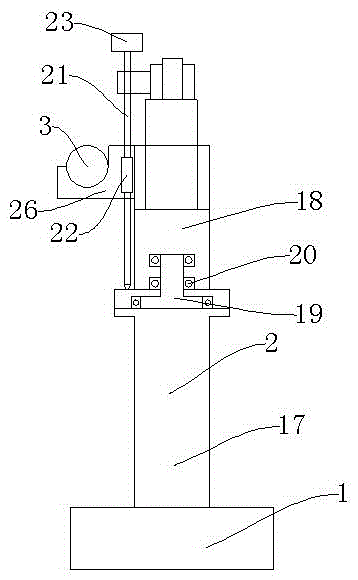

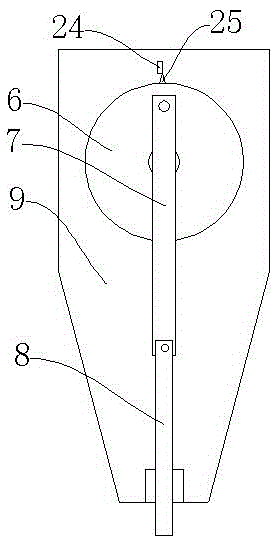

[0019] Such as figure 1 , figure 2 , image 3 As shown, the mortar making rice cake machine described in this embodiment includes a base 1, a column 2 is arranged on the base 1, and a cross arm 3 is arranged on the upper end of the column 2, and between the cross arm 3 and the base 1 is Horizontal rotation connection, a No. 1 motor 4 is set at one end of the cross arm 3, and a reducer 5 is set at the other end of the cross arm 3. The transmission connection between the No. 1 motor 4 and the reducer 5 is set at the output end of the reducer 5. There is a turntable 6, and a connecting rod 7 is connected to the periphery of the turntable 6. The other end of the connecting rod 7 is connected to a push rod 8. The push rod 8 and the connecting rod 7 are connected by a pin shaft. Housing 9, the push rod 8 and the transmission housing 9 are vertically slidingly connected, and the lower end of the push rod 8 protrudes from the transmission housing 9 and is connected with the hammer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com