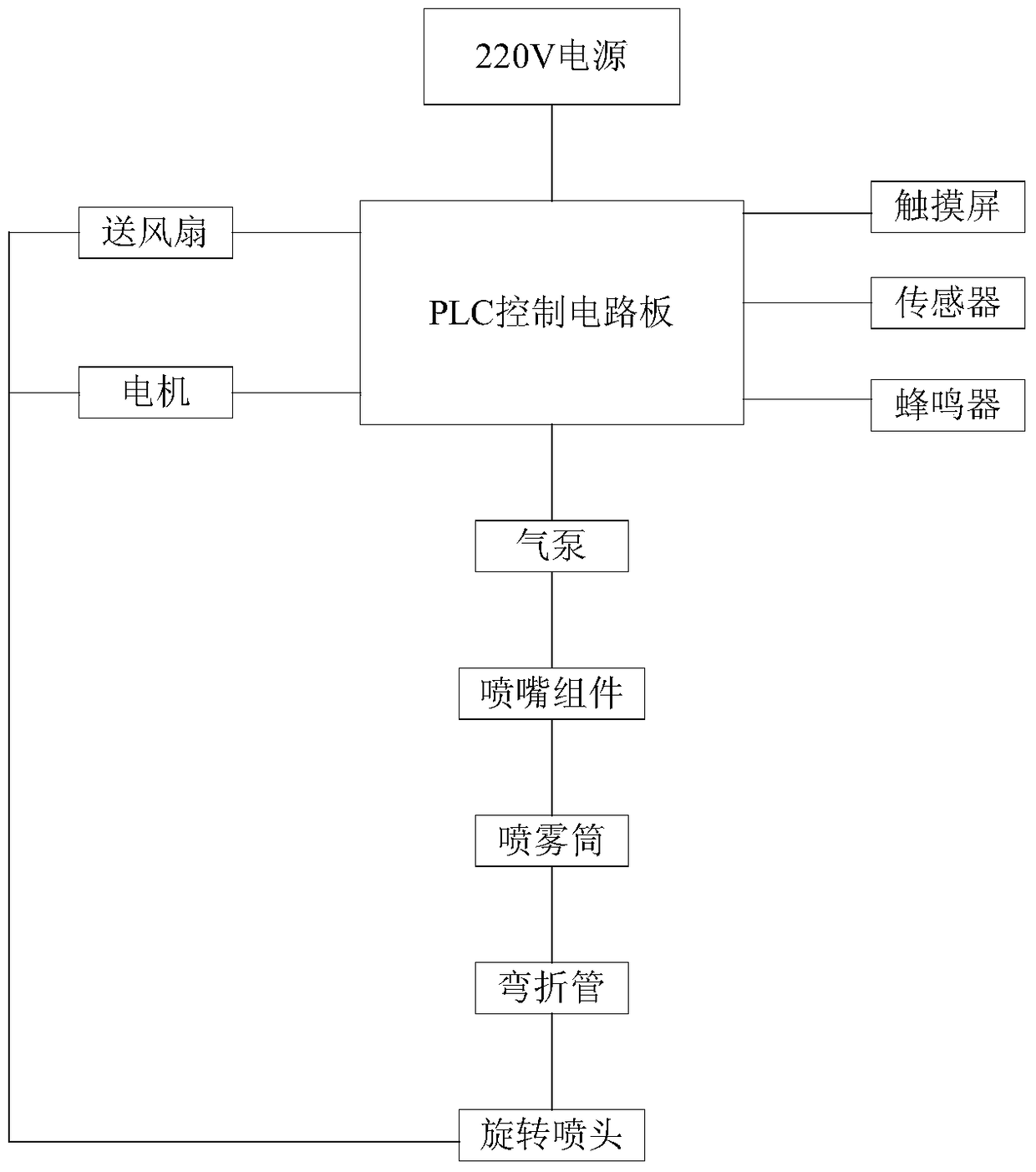

Dry fog disinfection machine

A sterilizer and dry fog technology, applied in the directions of disinfection, atomized substances, chemistry, etc., can solve the problems of unsatisfactory disinfection effect, high humidity in disinfection space, poor diffusion effect, etc. The effect of sterilization and intelligence, and short disinfection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

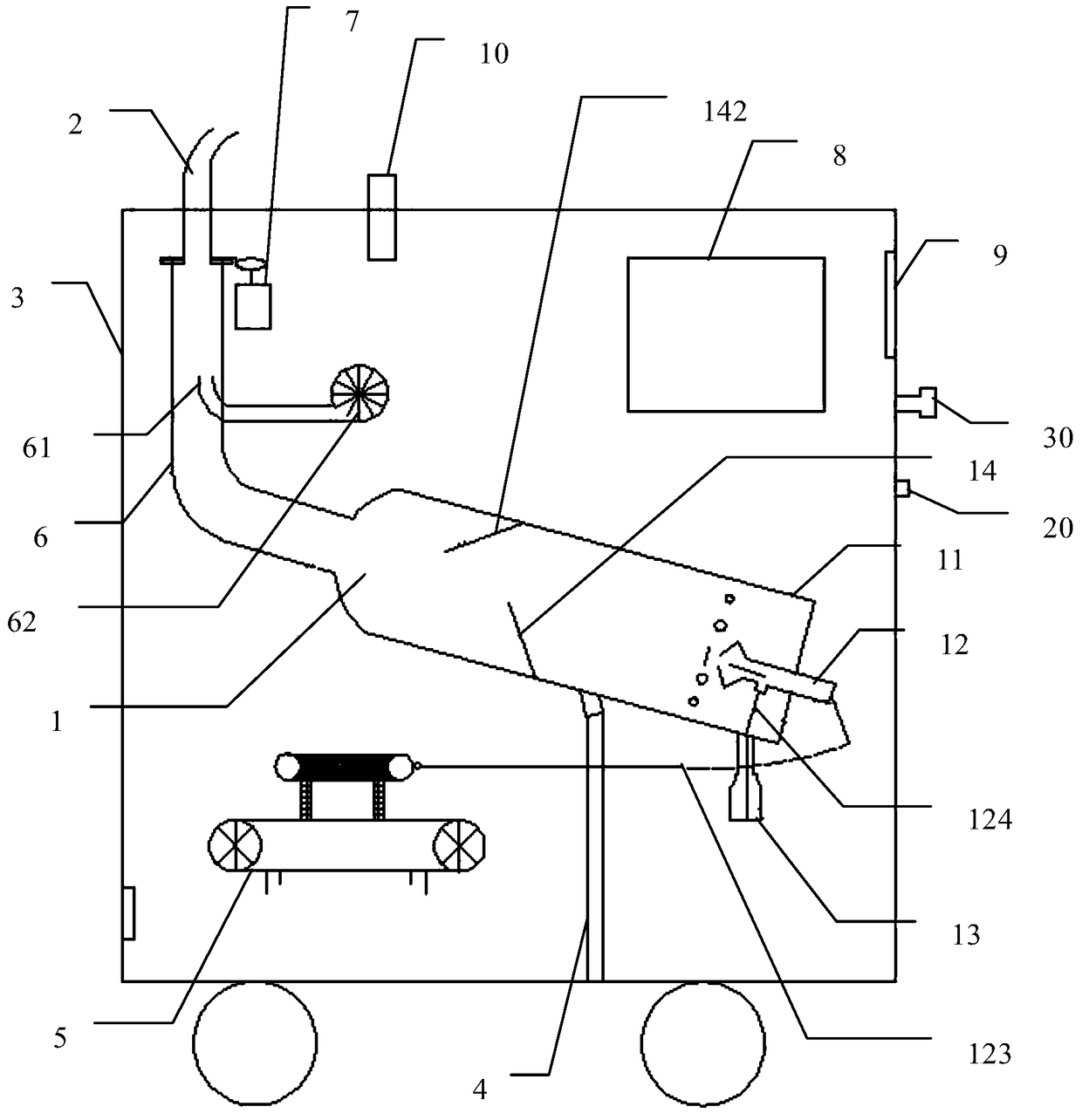

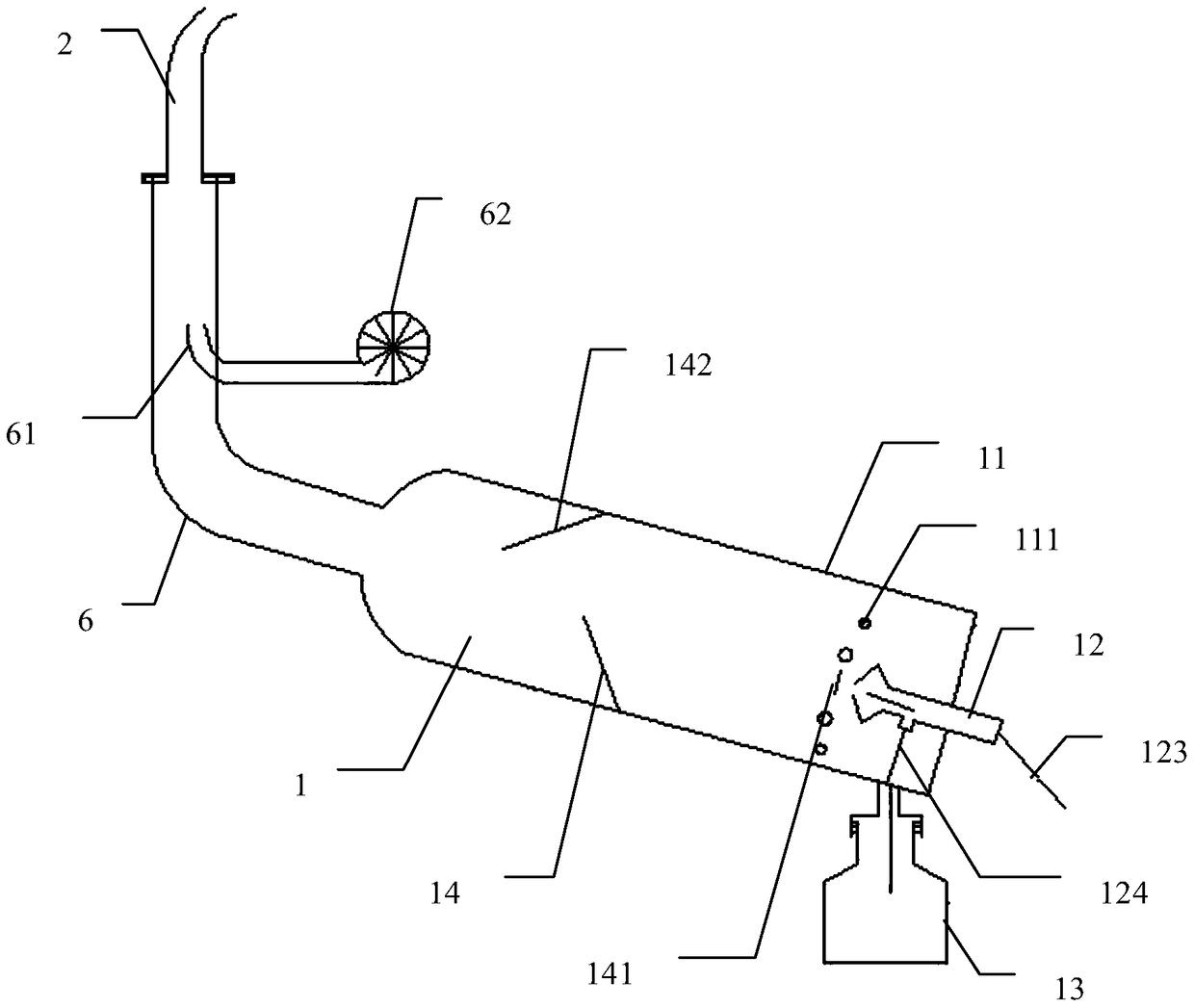

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0028] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0029] The invention provides a dry mist disinfection machine, which uses an air source to atomize the disinfection liquid into droplets with an average particle size of 3 to 5 microns, so as to sterilize all parts of the indoor space through the diffusion of dry mist. The spray assembly 1 and the nozzle assembly 2 are all arranged in a housing 3, and the spray assembly is fixed inside the housing through the bracket 4, and the upper end of the spray head assembly protrudes from the top of the housing, such as Figure 1~3 As shown, it includes: a spray assembly, which includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com