Humidifier and atomization enhancement device

A booster device and humidifier technology, which is applied in the field of atomization, can solve the problems of inability to guarantee the fogging effect, high cost of realization, complex structure, etc., and achieve the best market promotion prospects, improved ability, and long diffusion distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

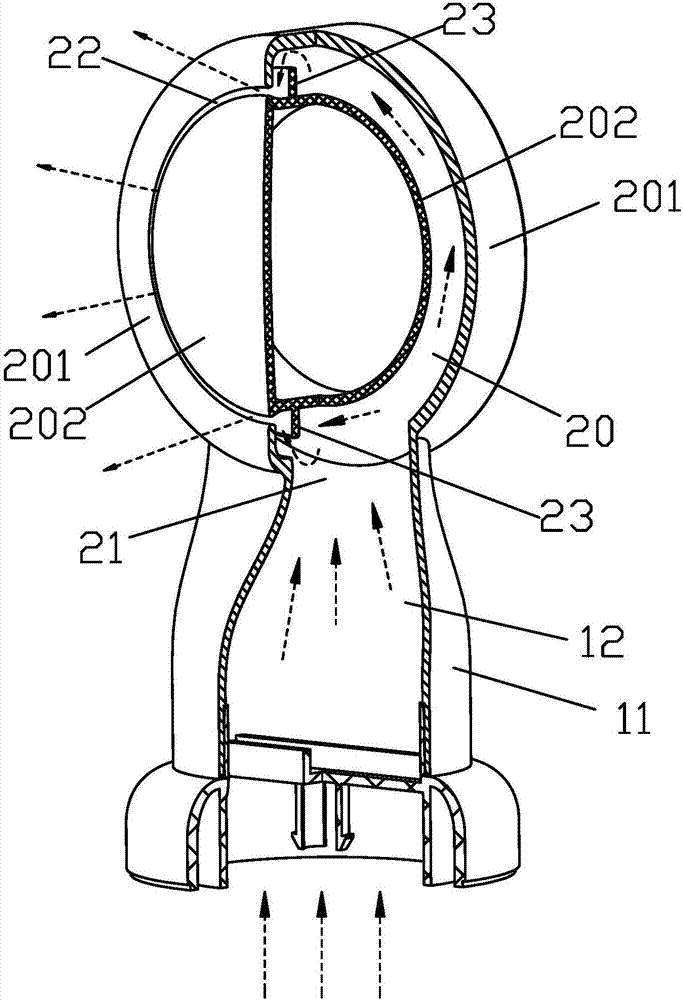

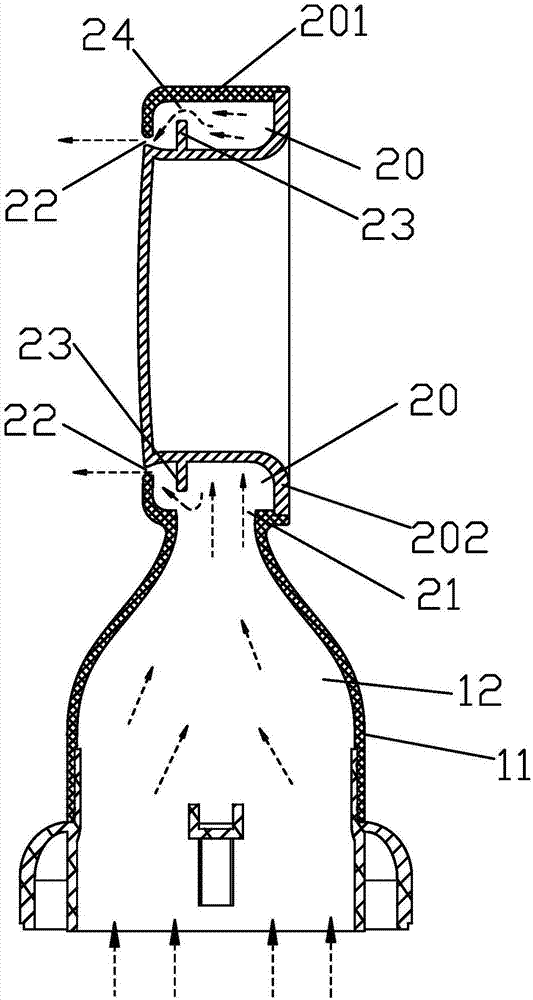

[0022] combine figure 1 and figure 2 as shown ( figure 1 and figure 2 The middle dotted line arrow represents the movement direction of water mist), the atomization enhancement device proposed by the present invention includes: a pressurized chamber 20 with a mist inlet 21 and a mist outlet 22, the mist inlet 21 of the pressurized chamber 20 and the mist outlet Pipe (not shown in the figure) is connected; Used to make the water mist gather in the pressurization chamber 20 to increase the stopper 23 of water mist pressure, this stopper 23 is fixed on the inner wall of the pressurization chamber 20 and is positioned at the water mist from The water mist flow path from the mist inlet 21 to the mist outlet 22, there is a water mist flow port 24 between the stopper 23 and the inner wall of the booster chamber 20, and the water mist after the pressure is increased is accelerated from the water mist flow port 24 Overflow and spray from mist outlet 22.

[0023] Wherein, the pres...

Embodiment 2

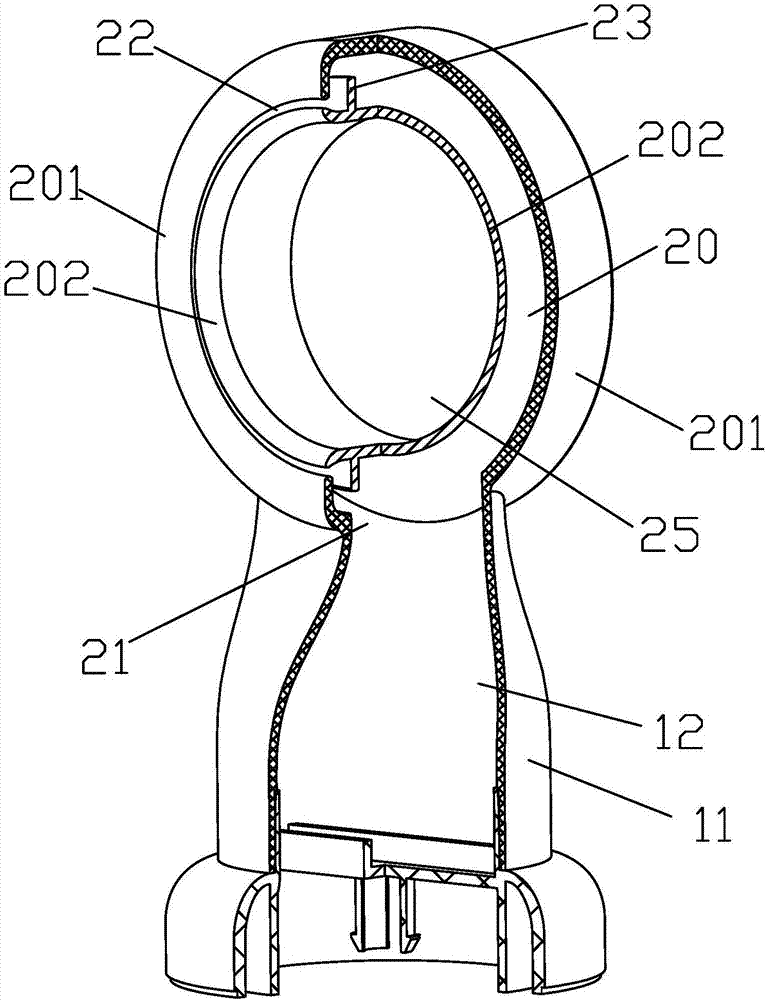

[0028] Considering that the water mist with smaller particles accelerates to be sprayed from the mist outlet 22 under the action of the internal pressure of the pressurized chamber 20, a negative pressure will be formed near the mist outlet 22, which will cause the sprayed water mist to be easily disturbed and affect the flow of the water mist. Diffusion distance and diffusion uniformity. Such as image 3 and Figure 4 As shown, an air duct 25 is set on one side of the pressurized chamber 20, and the negative pressure at the mist outlet 22 is supplemented through the air duct 25, so that the pressure at the mist outlet 22 is balanced, and the water sprayed from the mist outlet 22 is ensured. The fog will not be turbulent, so it can spread farther and more uniformly, further improving the fogging effect.

[0029] in, image 3 and Figure 4 In the shown embodiment, the pressurization chamber 20 is annular, the mist outlet 22 is a narrow and long annular slit, and the air duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com