Crushing device of caked powder material

A powder material and crushing device technology, which is applied in the direction of grain processing, etc., can solve the problems of cutting, conveying and using difficulties, and achieve the effects of convenient equipment maintenance, avoiding stuck, and protecting the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

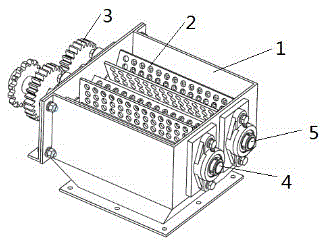

[0020] like figure 1 As shown, the box body 1 is outside the blade 2, and is fixed and sealed with the driving shaft 4 and the driven shaft 5 by bolts; the rotation of the motor drives the driving shaft 4 to rotate, and drives the driven shaft to rotate through the transmission gear 3, driving the welding on the two shafts The perforated blade 2 rotates.

[0021] When working, the material falls from the top of the box to the top of the blade 2, and the driving shaft 4 and the driven shaft 5 driven by the motor rotate in opposite directions, so that the blade 2 brings the material into the device. The two-axis blade 2 forms a The bite force breaks up the agglomerates, and through the cavity on the surface of the blade 2, the fineness of the agglomerates is controlled. When the agglomerates are broken down to a size smaller than the aperture, they fall to the outlet below to complete the crushing. The start and stop of the equipment is controlled by the air switch, and when fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com