Automatic mortar raw material screening equipment

A technology of automatic screening and sorting equipment, applied in lighting and heating equipment, filter screen, sand drying and other directions, can solve the problems of low production efficiency, high energy consumption, low heat energy utilization rate, etc., and achieve the goal of improving production efficiency and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

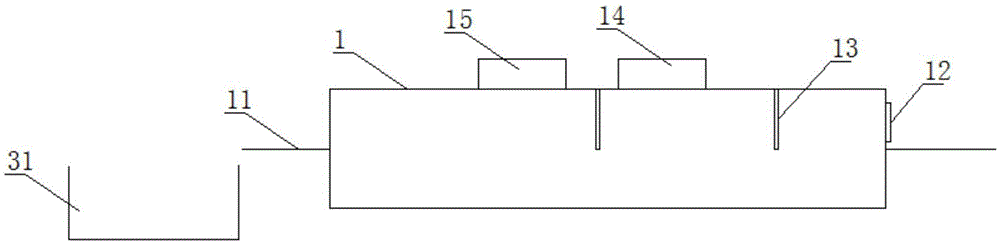

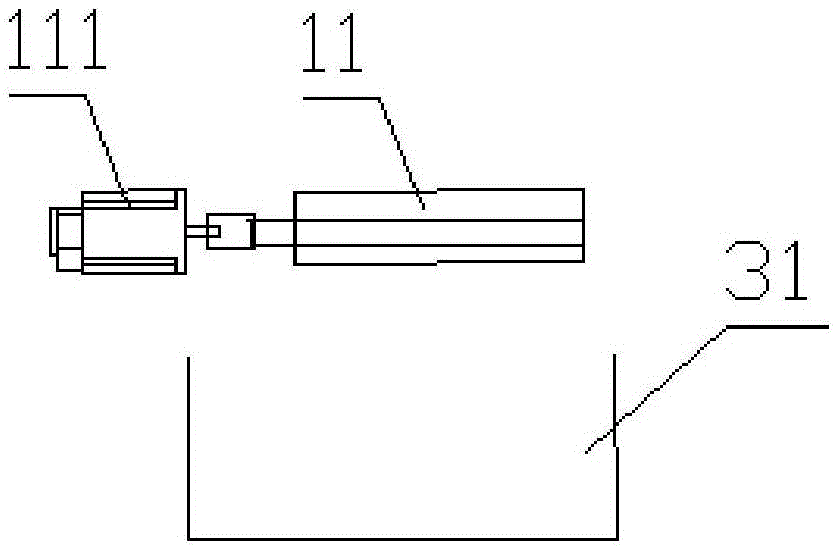

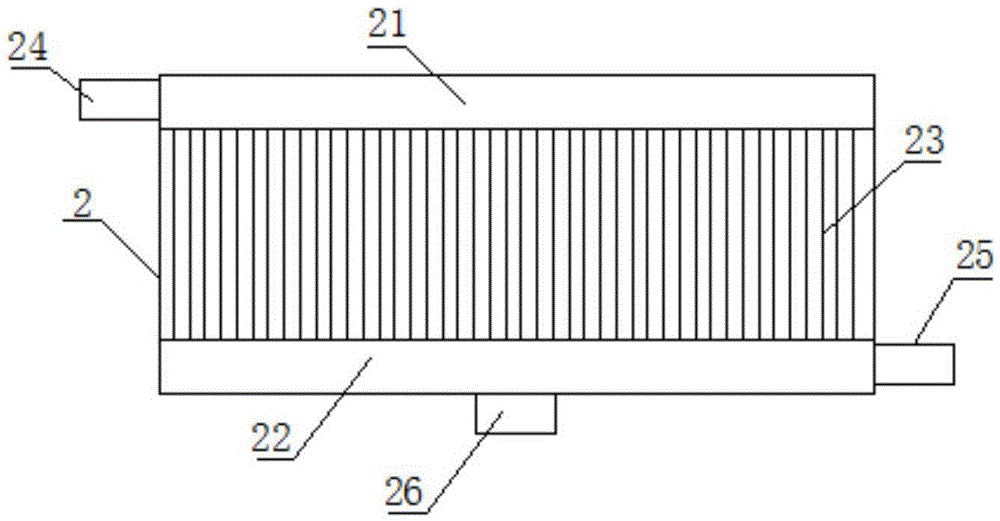

[0022] like Figure 1 to Figure 6 As shown, an automatic screening equipment for mortar raw materials includes a drying box 1 and a vibrating screen device, the front side of the drying box is provided with a drying box inlet, and the rear side of the drying box is provided with a drying box The outlet of the box is provided with a mortar raw material conveying mechanism in the drying box. like figure 2 As shown, the mortar raw material conveying mechanism includes a conveying belt 11 and a conveying motor 111. The conveying motor drives the conveying belt to convey from front to back along the drying box, and the inner cavity of the drying box is provided with flue gas adjacent to the inner wall. Pipeline 2, the flue gas pipeline introduces flue gas with waste heat to heat the drying box. The conveying motor 111 drives the conveyor belt 11 to convey along the front and rear directions of the drying box. The mortar raw materials that need to be dried are conveyed on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com