Investment mold centrifugal casting method with plugging device for mold shell dewaxing port and its device

A plugging device and centrifugal casting technology, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems that affect the metallurgical quality of castings, casting castings can not be judged good or bad by manual operation, and gunfire defects, etc., to achieve metallurgical Effects of quality improvement, surface porosity reduction, and gas generation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

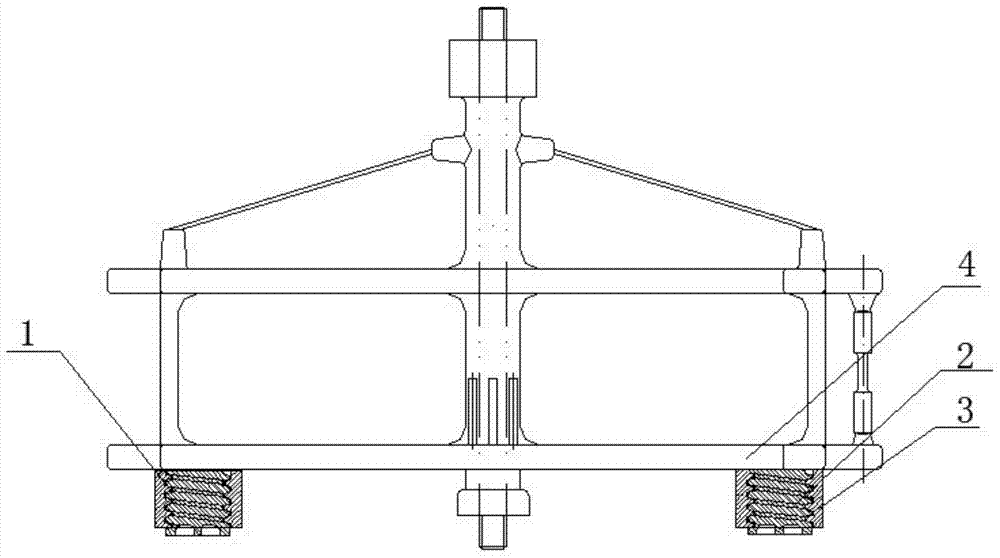

[0030] Example 1: Making a casting wax mold and making a ceramic plug 1 and an external thread wax mold 2 matching the wax mold; the external thread wax mold 2 is baked with a 90°C heating tube and bonded to the bottom of the wax mold mold assembly Carry out the coating process to make the shell; then cut off the surface coating layer of the external thread wax pattern 2 away from the frame to expose the external thread wax pattern 2, and then perform steam dewaxing, and after dewaxing, the shell is baked at a high temperature of 1060°C , keep warm for 3.5 to 4.5 hours after roasting; when the temperature in the furnace is cooled to 150°C and come out of the furnace, thread the ceramic plug 1 and the dewaxing port on the mold shell after firing to be flush with the bottom surface of the dewaxing port; The shell is centrifugally poured at a temperature of 900°C, the pouring speed is gradually increased from 0.5kg / s to 2kg / s, and the centrifugal speed is gradually increased from ...

Embodiment 2

[0031] Example 2: Making a casting wax mold and making a ceramic plug 1 and an external thread wax mold 2 matching the wax mold; the external thread wax mold 2 is baked with a 100°C heating tube and bonded to the bottom of the wax mold mold assembly Carry out the coating process to make the shell; then cut off the surface coating layer of the external thread wax pattern 2 away from the frame to expose the external thread wax pattern 2, and then perform steam dewaxing, and after dewaxing, the shell is baked at a high temperature of 1060°C , keep warm for 3.5 to 4.5 hours after roasting; when the temperature in the furnace is cooled to 150°C and come out of the furnace, thread the ceramic plug 1 and the dewaxing port on the mold shell after firing to be flush with the bottom surface of the dewaxing port; The shell is centrifugally poured at a temperature of 930°C, the pouring speed is gradually increased from 0.5kg / s to 2.5kg / s, and the centrifugal speed is gradually increased fr...

Embodiment 3

[0032] Example 3: Making a casting wax mold and making a ceramic plug 1 and an external thread wax mold 2 matching the wax mold; the external thread wax mold 2 is baked with a 110°C heating tube and bonded to the bottom of the wax mold mold assembly Carry out the coating process to make the shell; then cut off the surface coating layer of the external thread wax pattern 2 away from the frame to expose the external thread wax pattern 2, and then perform steam dewaxing, and after dewaxing, the shell is baked at a high temperature of 1070°C , keep warm for 3.5 to 4.5 hours after roasting; when the temperature in the furnace is cooled to 150°C and come out of the furnace, thread the ceramic plug 1 and the dewaxing port on the mold shell after firing to be flush with the bottom surface of the dewaxing port; The shell is centrifugally poured at a temperature of 950°C, the pouring speed is gradually increased from 0.5kg / s to 3kg / s, and the centrifugal speed is gradually increased from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com