Double-station assembly equipment applied to mechanical workpiece flow line production

An assembly equipment and assembly line technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of assembly line workbench equipment occupying a large space, the operator's walking range is large, and the production efficiency of the enterprise is affected. Achieve the effect of reducing the range of moving operations, novel structure design, and reducing horizontal or vertical line change operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

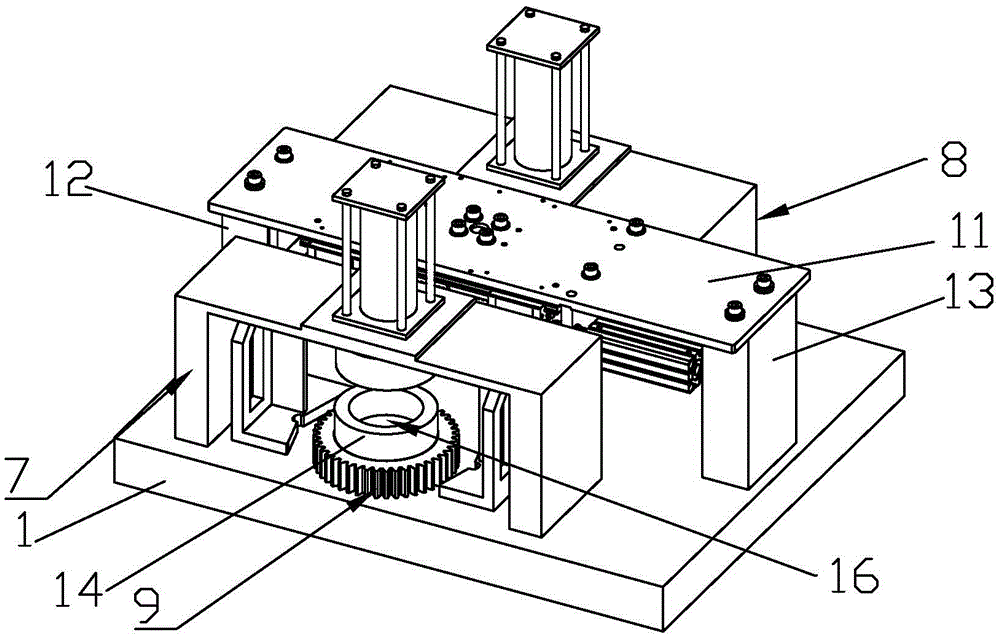

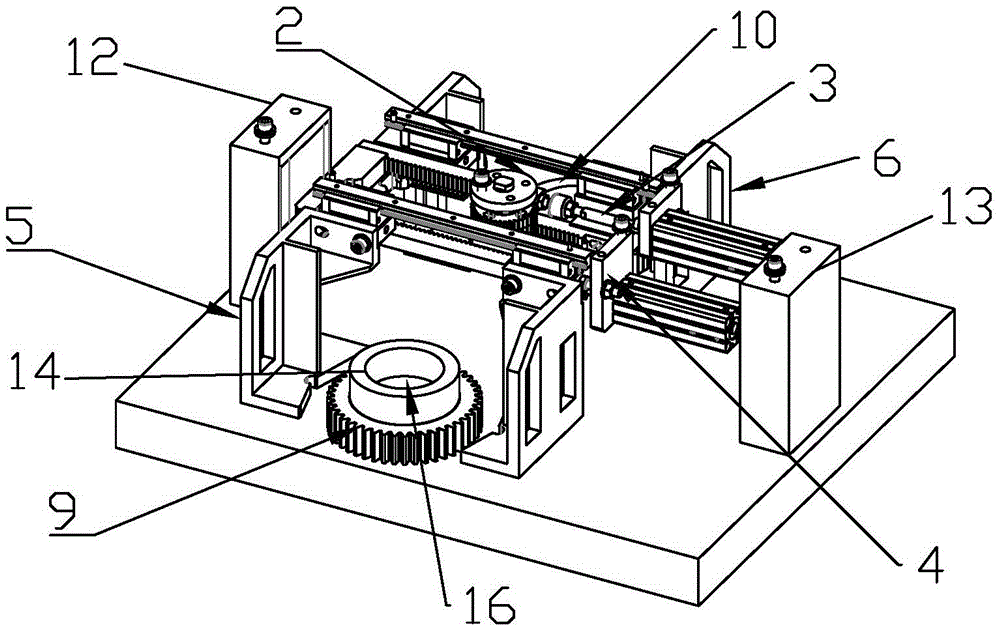

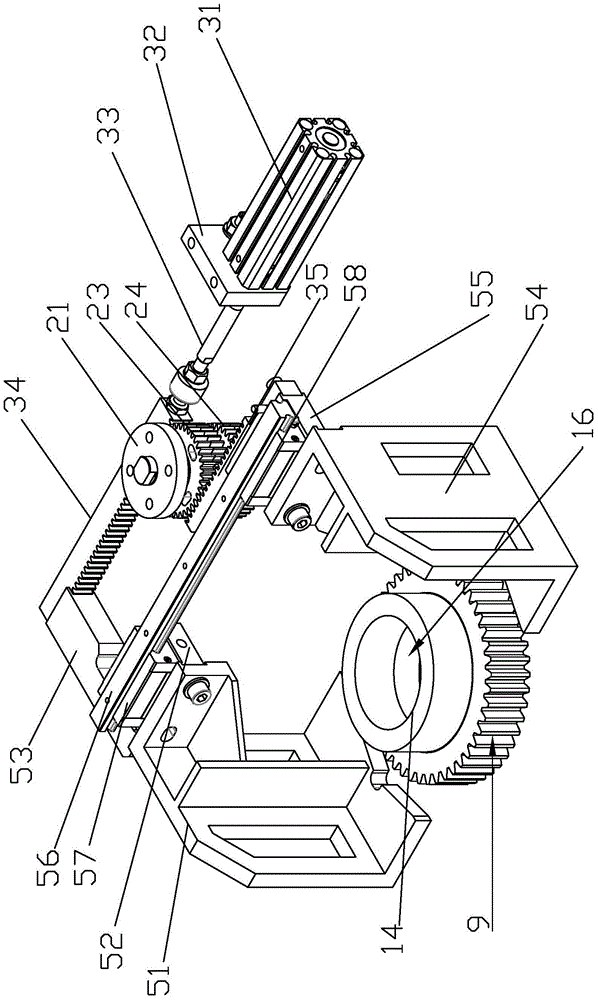

[0031] Such as Figure 1 to Figure 6 As shown, a double-station assembly equipment applied to the production of mechanical workpiece assembly lines includes a base 1 and a mounting bracket. The mounting bracket includes a left mounting bracket 12 and a right mounting bracket 13. The left mounting bracket 12 is installed on the left side of the base 1. The right mounting bracket 13 is installed on the right side of the base 1, a mounting plate 11 is provided between the left mounting bracket 12 and the right mounting bracket 13, and a centering device 2 is provided below the mounting plate 11, and the centering device 2 is connected with a clamping drive device, the clamping driving device includes a first clamping driving device 3 and a second clamping driving device 4, the first clamping driving device 3 and the second clamping driving device 4 are installed under the mounting plate 11, the first clamping Tight driving device 3 is connected with first clamping device 5, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com