A fabric quantitative cutting machine

A cutting machine and fabric technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of manual cutting, poor adaptability, and inability to realize automatic quantitative cutting, and achieve quantitative cutting, wrinkle prevention, accurate cutting, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

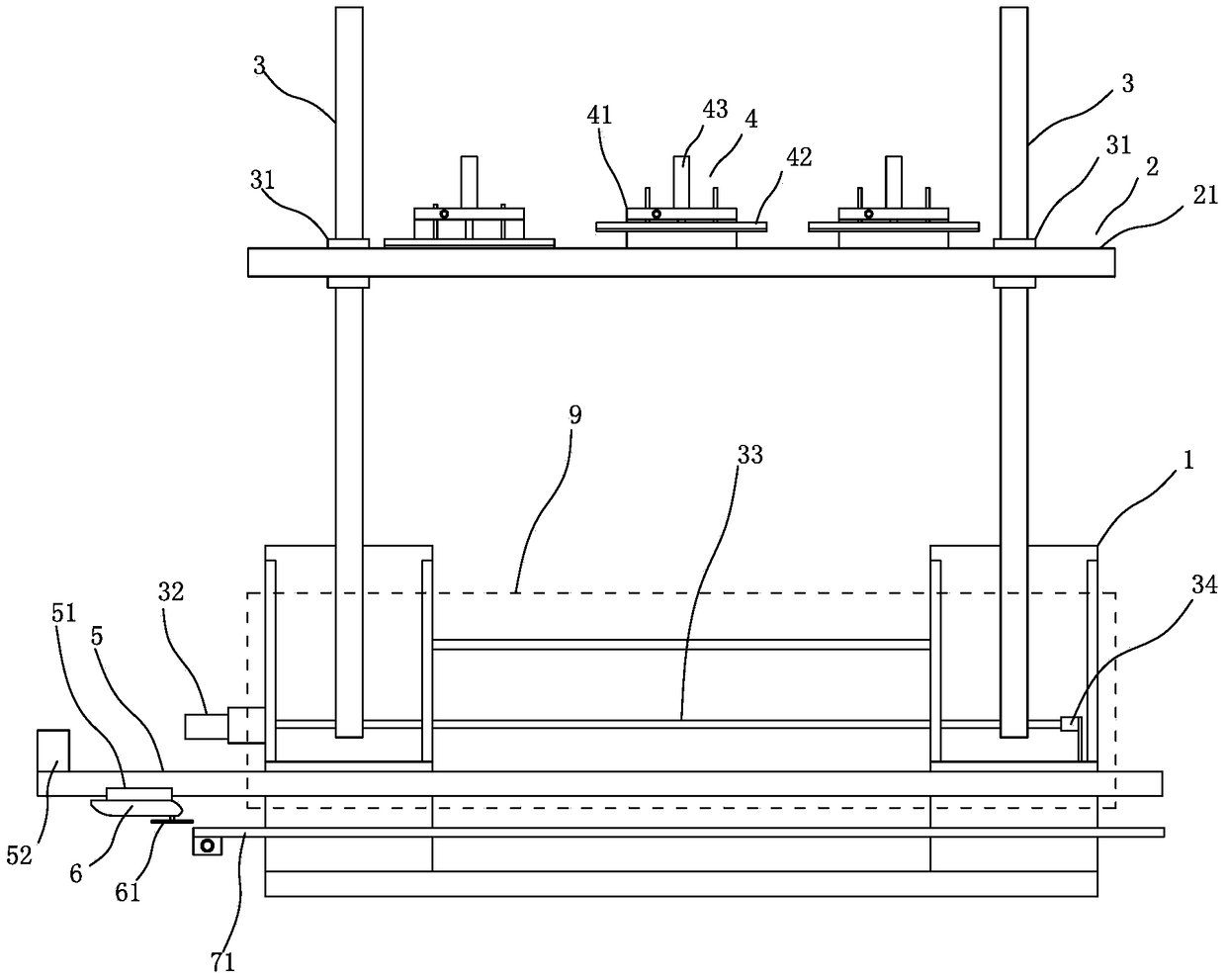

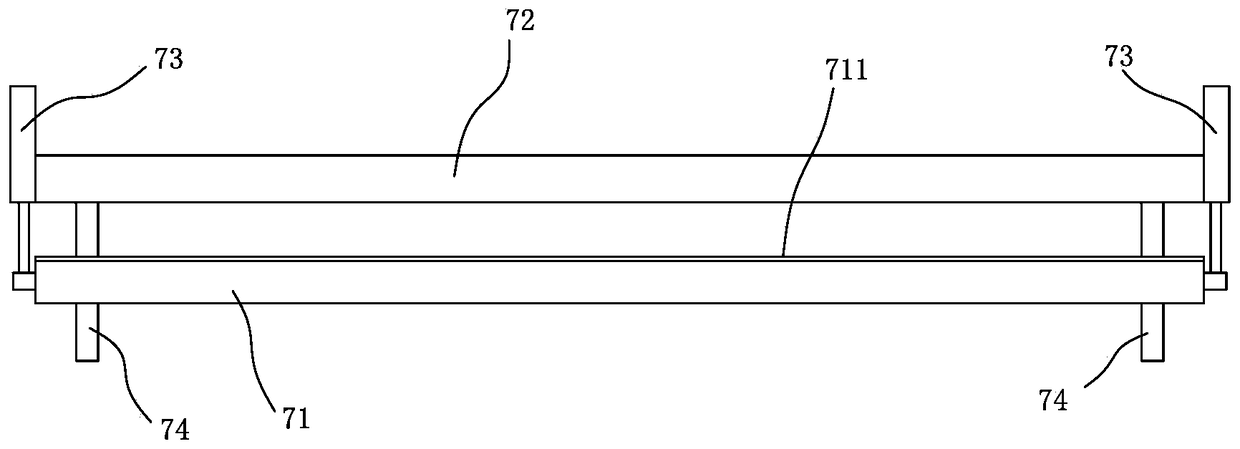

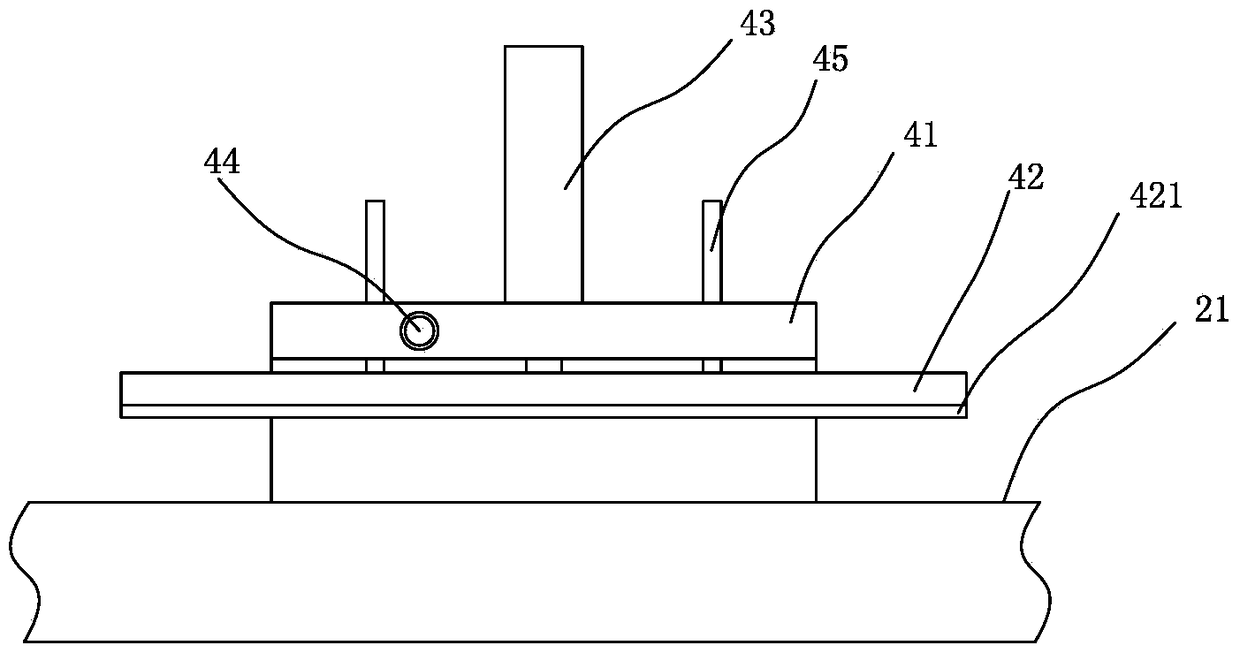

[0025] refer to Figure 1 to Figure 8 As shown, a cloth quantitative cutting machine includes a frame 1, a lifting frame 2, a vertical movement mechanism, a first cloth clamping mechanism, a second cloth clamping mechanism, a cutting device 6, a lateral movement mechanism, a cloth turning mechanism and a control device.

[0026] The vertical movement mechanism includes two vertical linear modules 3 arranged at intervals on the frame 1, and a first motor 32 that drives the two vertical linear modules 3 to move synchronously through a synchronous shaft 33. The lifting frame 2 is arranged on the two vertical linear modules. 3, an encoder 34 connected to the control device is provided on the synchronous shaft 33 between the sliding seats 31.

[0027] The lifting frame 2 comprises two fixed seats 22 arranged on two vertical linear modules 3 slide seats 31 and a horizontal object stage 21 hinged between the two fixed seats 22 by a hinge 23. To turn over between states, a first air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com