Back bolt combination device for stone veneer installation and installation method thereof

A technology of combined device and installation method, applied in covering/lining, building, building structure, etc., can solve the problems of high price, limitation, tensile strength limitation, etc., to improve the flexibility of application and improve the convenience of use , the effect of reducing the cost of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

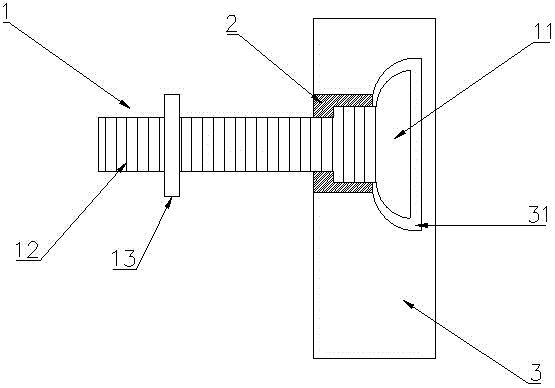

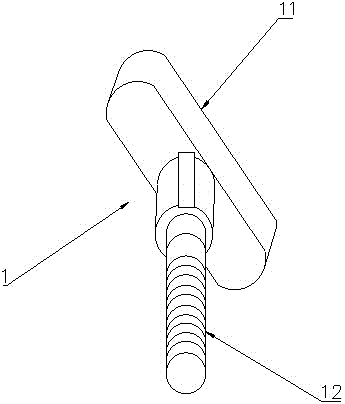

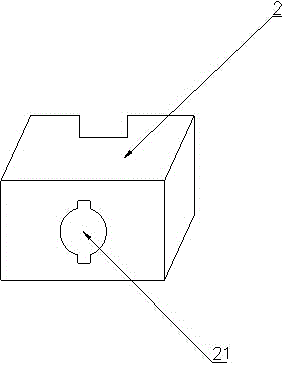

[0034] Please refer to, the back bolt combination device of the present invention includes a T-shaped countersunk head 11, a screw rod 12, a positioning member 2, a nut 13, and a stone veneer 3 provided with a long groove 31 matching the back bolt combination device; The T-shaped countersunk 11 and the screw 12 are a fixed body, referred to as the T-shaped screw 1; the positioning part 2 is provided with a hole 21 for the screw to pass through, and the positioning part 2 enters the T-shaped countersunk 11 through the screw 12 One end is fixedly combined, and the fixed combination is that the combination of the positioning part 2 and the T-shaped screw 1 is provided with a mutual interlocking function, and the described interlocking function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com