Ground test tail gas heat recycling and silencing tower for aero-engine

A technology for aero-engine and ground testing, applied in jet engine testing, gas turbine engine testing, engine components, etc., can solve problems such as energy waste, and achieve the effect of less investment and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

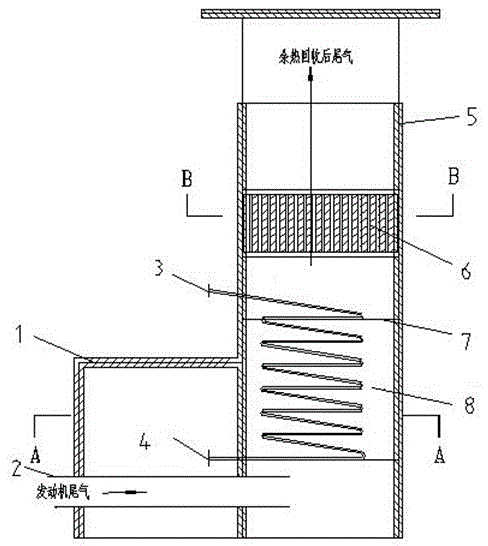

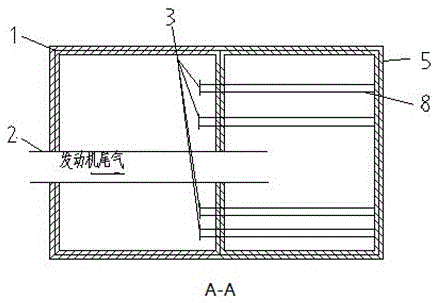

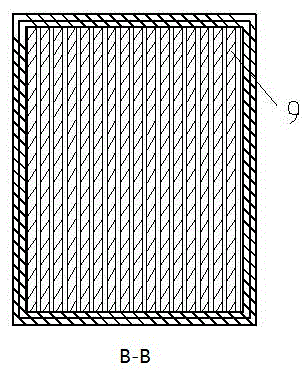

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

[0013] An aero-engine ground test tail gas heat recovery silencer tower consists of 2-exhaust ejector tube, 1-heat insulation and sound insulation room, 5-exhaust tower, 6-muffler device, 8-heat exchanger. 1-Heat and sound insulation room is connected with 5-exhaust tower, and the high temperature resistant 2-exhaust ejector made of metal material is connected with 5-exhaust tower through 1-heat and sound insulation room. 6-muffling device, 8-heat exchanger are built in 5-exhaust tower, 6-muffling device is located at the upper part of 5-exhaust tower, 8-heat exchanger is located at the lower part of 5-exhaust tower.

[0014] 1-Heat insulation and sound insulation room is a building with a brick-concrete structure on the outside and heat and sound insulation materials on the inside, which can play the role of sound insulation and heat insulation. The engine exhaust pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com