Novel pneumatic three-way controller

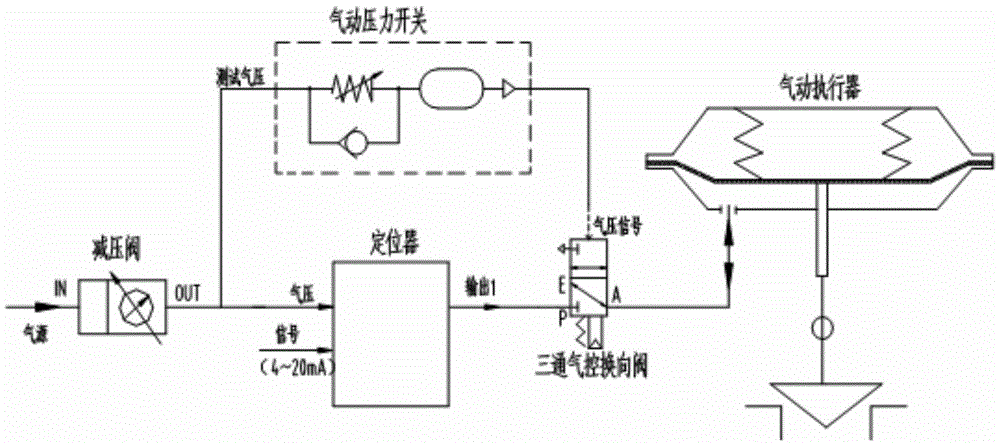

A controller and three-way technology, applied to multi-way valves, engine components, valve details, etc., can solve the problems of product connection pipe leakage, large machine shape, and complicated debugging, so as to ensure sealing performance and low manufacturing cost , the effect of wide pressure regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

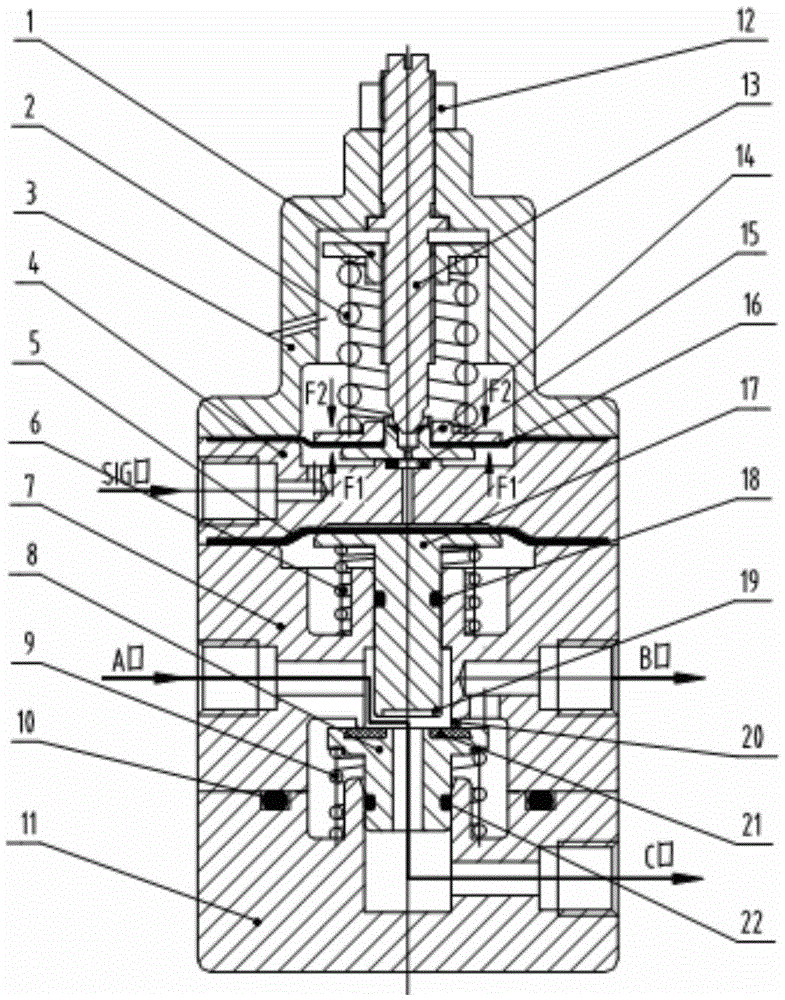

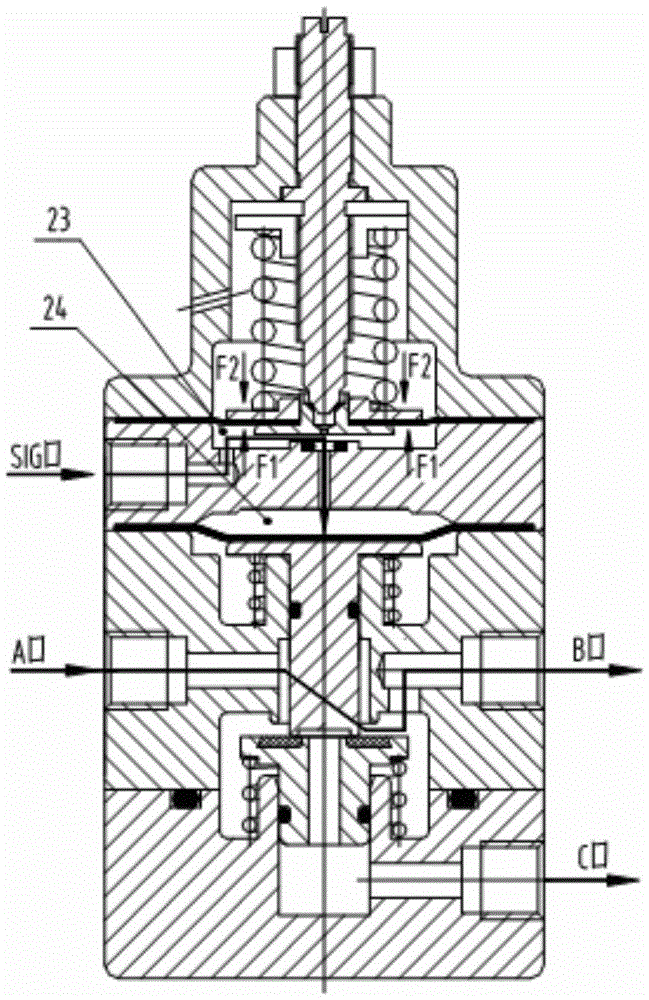

[0026] Such as figure 2 , 3 As shown, the present invention provides a new type of pneumatic three-way control that can flexibly set the fault value of the air source pressure according to the site requirements, automatically monitor the air source pressure, and make the pneumatic instrument automatically reset or run to the full open / full close position according to the control requirements. to replace the traditional control scheme that uses a combination of two pneumatic components. When the input pressure of the SIG port of the new pneumatic three-way controller is greater than the air source failure set value set by the pressure regulating spring 2, the A port (the first inlet) of the controller is connected to the C port (the second outlet), and the B port is connected. Port (the first outlet) is not connected to port A and port C; when the input pressure of the SIG port (signal port) of the controller is less than the set value of the air source failure, the port A of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com