Built-in pump LNG (liquefied natural gas) storage tank

A storage tank and pump well technology, applied in the field of LNG storage equipment, can solve the problems of wasting resources and maintenance time, unable to replace the valve core and valve seat seal, non-removable, etc., to achieve long service life, reduce maintenance costs and time, fatigue reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

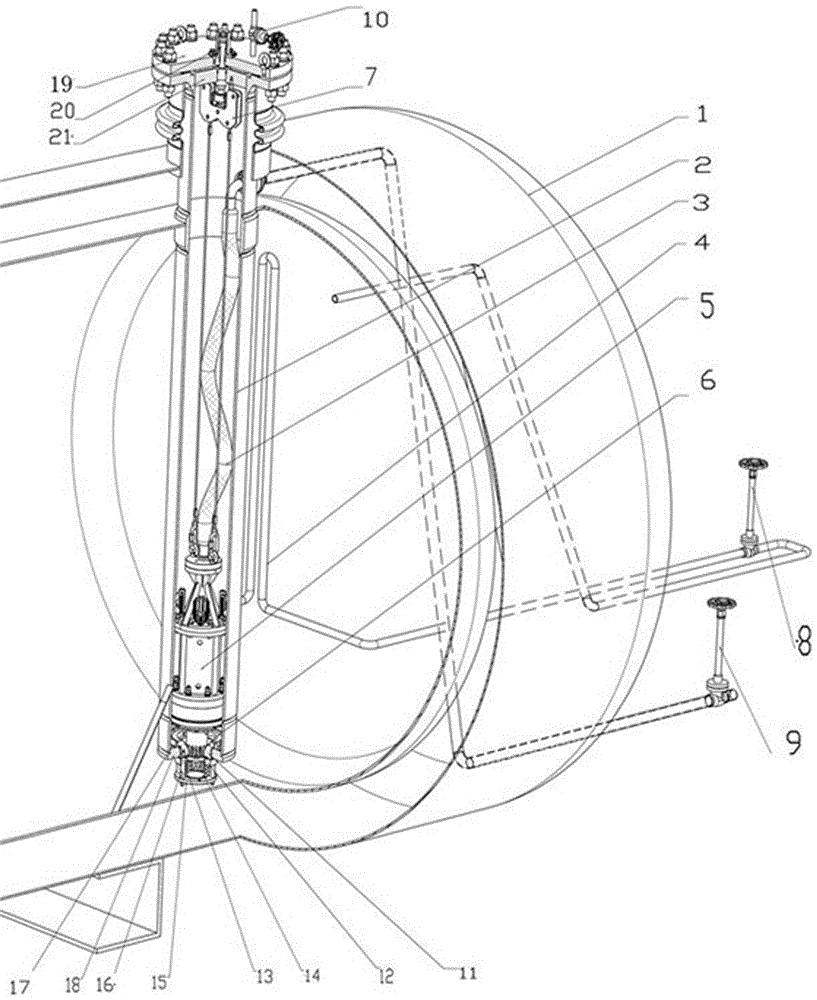

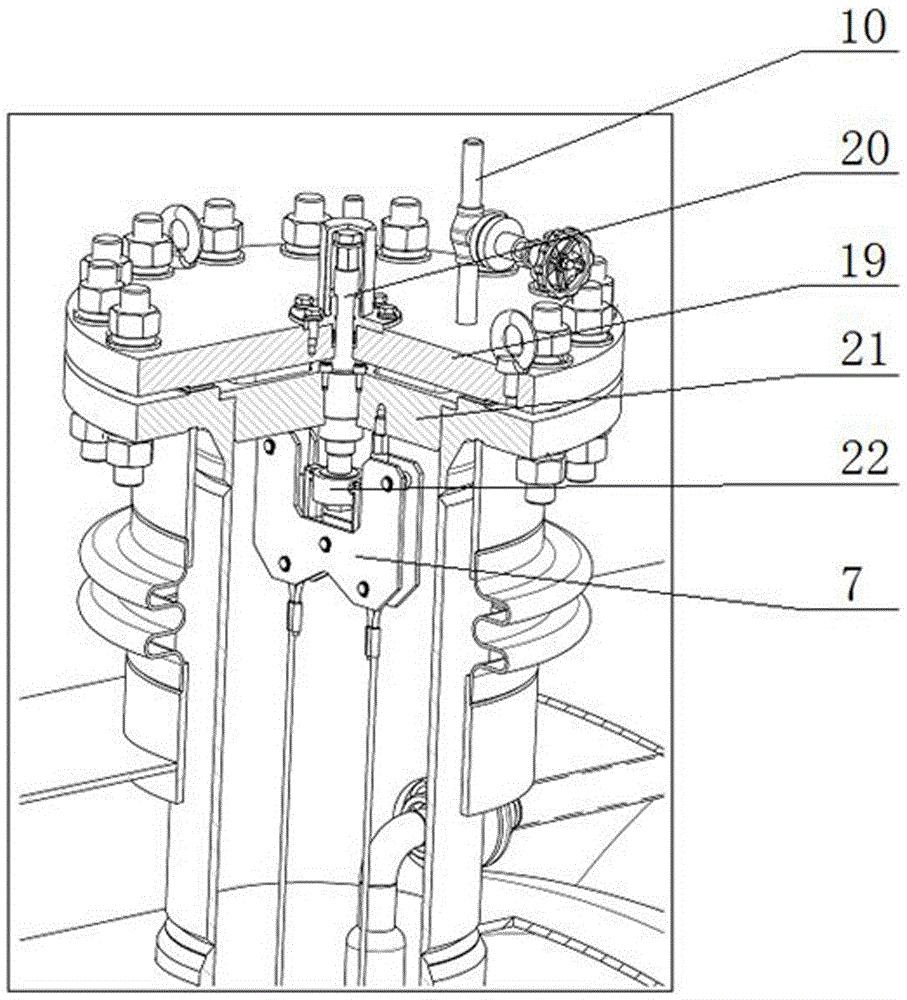

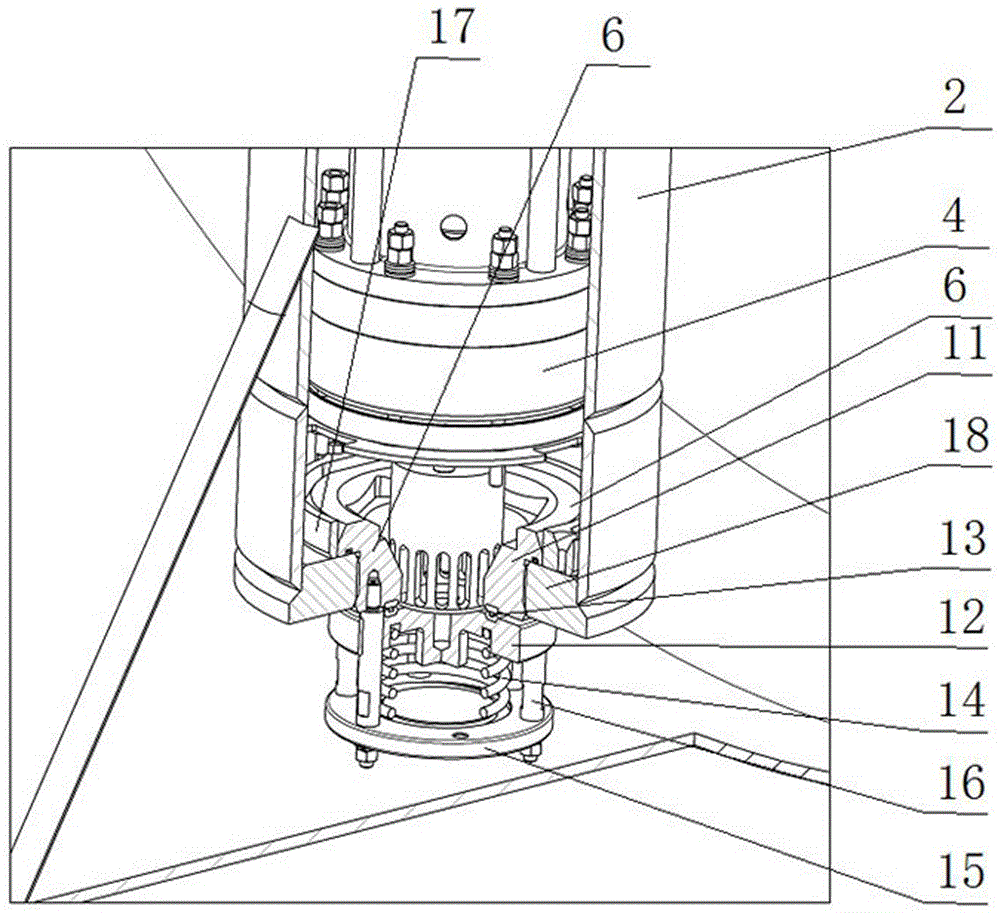

[0034] like Figure 1-3 As shown, the LNG storage tank with built-in pump of the present invention includes an LNG storage tank body 1 and a pump well 2. The pump well 2 is connected to the LNG storage tank body 1 and extends into the LNG storage tank body 1, and is located in the pump well 2. An LNG submersible pump 5 is provided, one end of the liquid outlet hose 3 is connected to the LNG submersible pump 5, and the other end of the liquid outlet hose 3 should be connected to the outside of the pump well 2; And lift the hoisting mechanism of the LNG submersible pump 5 and the pump well flange cover 19 for sealing the pump well 2; a pump well bottom valve 6 is provided at the bottom of the pump well 2, and the pump well bottom valve 6 includes a valve seat 11, a valve The core 12 and the spring seat 15, the spring seat 15 is fixedly connected to the valve seat 11 through the valve core guide post 16, the valve core 12 is sleeved on the valve core guide post 16 and is pressed ...

specific Embodiment 2

[0044] According to the LNG storage tank with built-in pump described in Embodiment 1, the disassembly method of its LNG submersible pump 5:

[0045] Step 1: Rotate the operating screw 20 to make the LNG submersible pump 5 rise until the valve core 12 of the pump bottom valve 6 is fitted and sealed with the valve seat 11 under the action of the elastic force of the spring 14, and then the pressure at the outlet of the LNG storage tank body 1 is detected. To confirm that the pump bottom valve 6 is closed;

[0046] Step 2: Pour nitrogen or inert gas into the pump well 2 to remove the LNG liquid in the pump well 2;

[0047] Step 3: Close the valves connected to the LNG storage tank body 1, disassemble the pump well flange cover 19, lift the LNG submersible pump 5 along the pump well 2, and then replace or disassemble the lifted LNG submersible pump 5 .

[0048] Due to the above method, it can ensure that the LNG submersible pump 5 can be quickly disassembled for easy replacemen...

specific Embodiment 3

[0049] According to the LNG storage tank with built-in pump described in Embodiment 1, the assembling method of its LNG submersible pump 5:

[0050] Step 1: Check that the valves connected to the LNG storage tank body 1 are indeed closed, seal the pump well flange 19 on the pump well 2, and introduce nitrogen or inert gas into the pump well 2 to clean the pump well 2. Purging, then venting nitrogen or inert gas;

[0051] Step 2: Open the pump well flange cover 19, hoist the LNG submersible pump 5 into the pump well 2, then cover the pump well flange cover 19 again and confirm that the pump well 2 is sealed;

[0052] Step 3: Rotate the screw 20 to make the LNG submersible pump 5 descend, and the LNG submersible pump 5 pushes the valve core 12 under the action of gravity to open the pump bottom valve 6, open the valves connected to the LNG storage tank body 1, and detect. Check the pressure at the outlet of the LNG storage tank body 1 and confirm that the pump bottom valve 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com