Dryers for fiber production

A dryer and fiber technology, applied in non-progressive dryers, dryers, drying chambers/containers, etc., can solve the problem of incapable fiber surface oiling agent treatment, etc., and achieve good drying effect and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

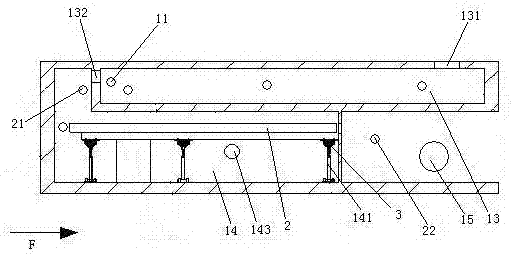

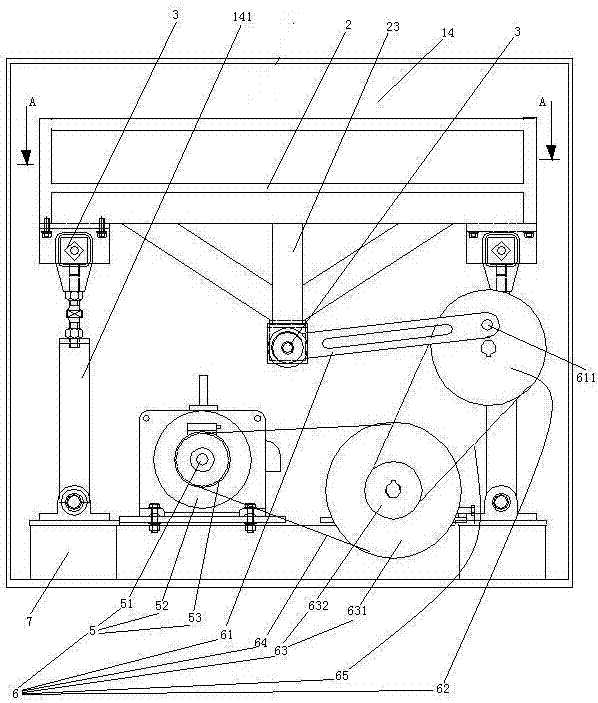

[0029] Embodiment one, see figure 1 , a dryer for fiber production, comprising a shell 1. An oil agent chamber 13 and a drying chamber 14 are sequentially arranged in the housing 1 from top to bottom. The oil chamber 13 is provided with an inlet hole 131 and an outlet hole 132 . Several first guide rollers 11 are arranged in the oil chamber 13 . A wire winding machine 15 is also provided in the casing 1 . The wire winding machine 15 is located on the right side of the drying chamber 14 .

[0030] The drying chamber 14 is provided with a support pendulum 141, a drying cylinder 2 and a heating mechanism for heating the drying cylinder. The heating mechanism 142 is an electric heating wire arranged in the drying drum 2 . An exhaust port 143 is provided in the drying chamber 14 .

[0031] The drying drum 2 is swingably supported in the drying chamber 14 by at least two support swing rods 141 . The upper end of the support swing rod 141 is connected with the drying cylinder ...

Embodiment 2

[0044] Embodiment two, the difference with embodiment one is:

[0045] see Figure 10 , The bottom wall of the drying cylinder 2 is provided with an inner cavity 25 . The inner cavity 25 is provided with an air outlet hole 26 penetrating into the drying cylinder 2 . The top wall of the drying cylinder 2 is provided with vent holes 27 .

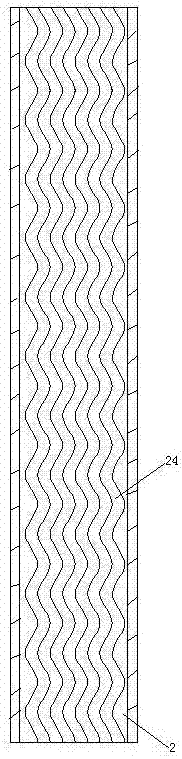

[0046] The air outlet hole 26 is staggered with the anti-slip groove 24, which can more effectively promote the fibers to roll under the action of the anti-slip groove. The inner chamber 25 is provided with a roller 9 . The roller 9 is a tubular structure. An accelerator lever 91 is arranged in the roller 9 . The acceleration lever 91 can accelerate the rolling of the roller 9 in the inner cavity 25 . The extension direction of the roller shaft 9 is the same as that of the drying cylinder 2 .

[0047] see Figure 11 , A plurality of air grooves 92 are provided on the peripheral surface of the roller 9 . The air grooves 92 extend axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com