Drying device for PCBs (Printed Circuit Boards)

A printed circuit board and drying device technology, which is applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problems of shortened service life of water-absorbing sponge, rapid drying of residual liquid, and reduced drying performance, etc. Long life, enhanced drying effect, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

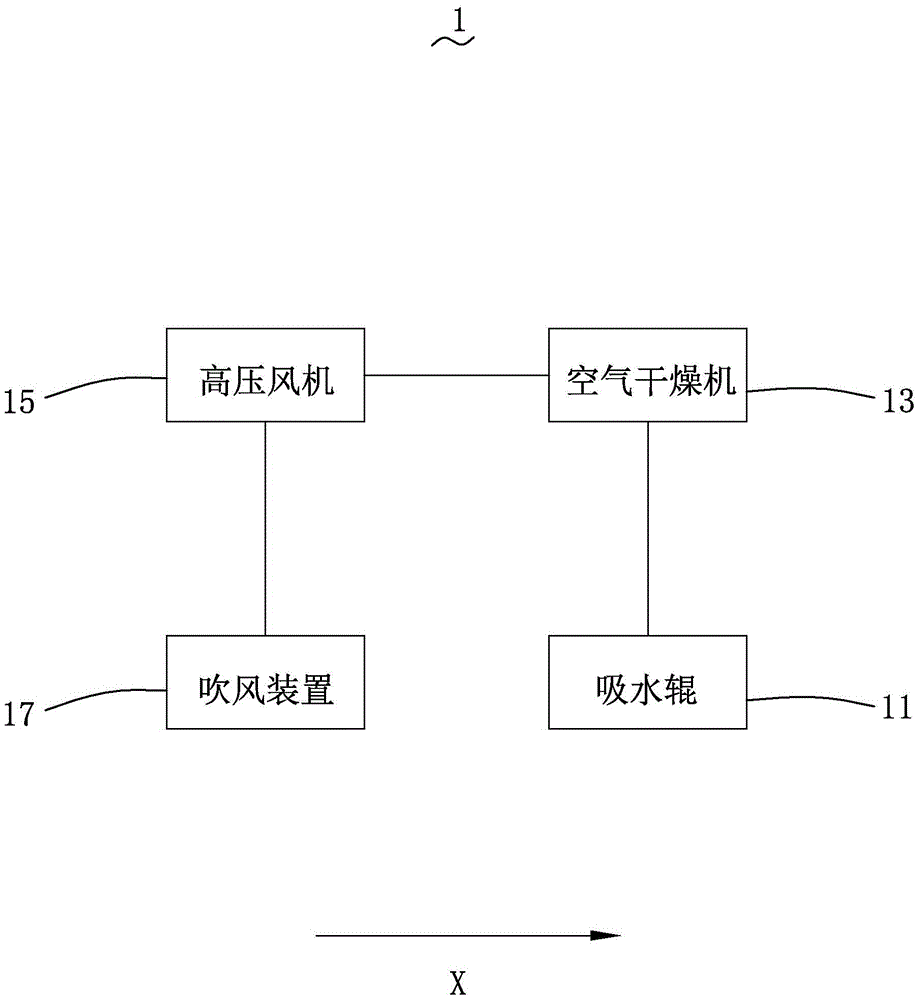

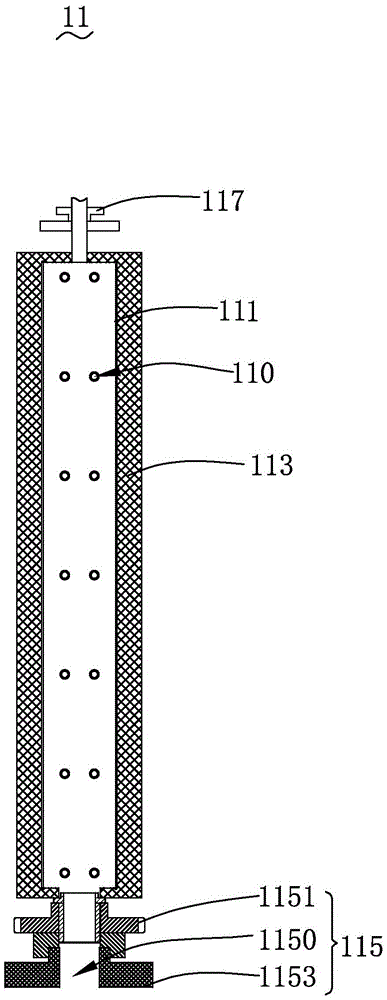

[0018] see figure 1 , is a structural schematic diagram of the printed circuit board drying device of the present invention. The printed circuit board drying device 1 includes a water suction roller 11 , an air dryer 13 , a high-pressure fan 15 and a blowing device 17 . Described suction roller 11, air drier 13, high-pressure blower 15 and blowing device 17 are connected successively, and described air drier 13 is arranged between described suction roller 11 and described high-pressure blower 15, and described high-pressure blower 15 is located at Between the air dryer 13 and the blowing device 17 , air is sucked in through the water suction roller 11 and drawn out by the blowing device 17 , and the blowing device 17 and the water suction roller 11 are spaced apart. Wherein, the water suction roller 11 and the blowing device 17 perform drying treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com