Rapid workpiece oil and water removing system

A fast, workpiece-based technology, applied in the direction of progressive dryers, drying solid materials, dryers, etc., can solve the problems that cannot form an assembly line, cumbersome steps, time-consuming and labor-intensive, etc., and achieve simple and novel structure, simple operation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

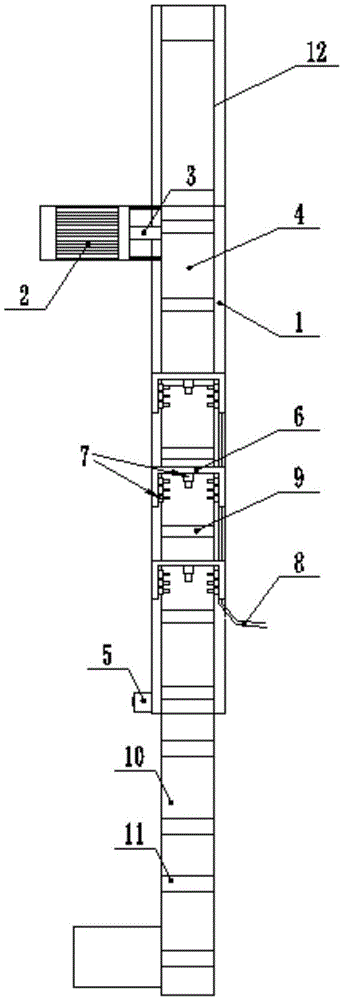

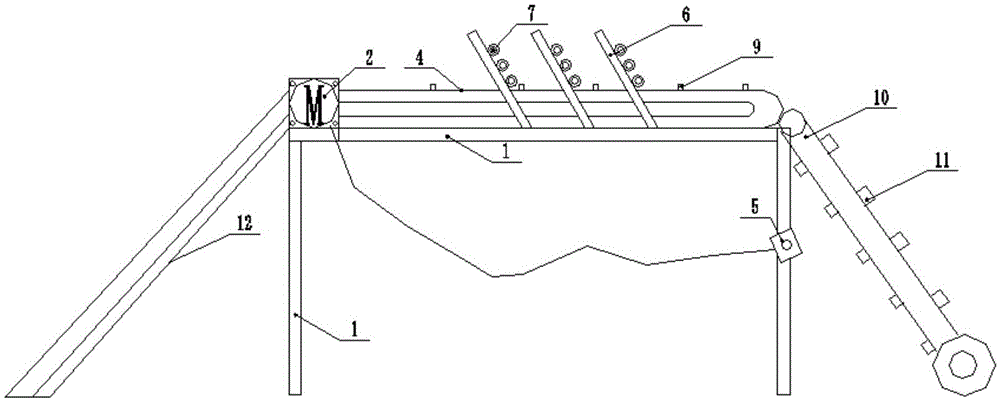

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0016] like Figure 1-2 As shown, a rapid degreasing and water removal system for workpieces includes a support frame 1 on which a conveyor belt 4 and a motor 2 are arranged, and the output shaft 3 of the motor 2 is connected to the driving wheel shaft center of the conveyor belt 4 connection, a motor speed control switch 5 is installed on the support frame 1, the motor speed control switch 5 is electrically connected to the motor 2, the conveyor belt 4 is transported by a belt, and a plurality of stoppers 9 are installed on the surface of the conveyor belt 4 3 arched air nozzle supports 6 are arranged across the two sides of the conveyor belt 4, and seven described air nozzles 7 are arranged on each of the arched air nozzle supports 6. Two of the arched air nozzle supports 6 Three groups of said air nozzles 7 are arranged opposite to each other in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com