Method for monitoring and diagnosing super-high-speed small box packaging machine having multiple condition characteristic

A diagnostic method and ultra-high-speed technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve the problems of not meeting the actual needs of cigarette production and difficult to obtain PLC parameter data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

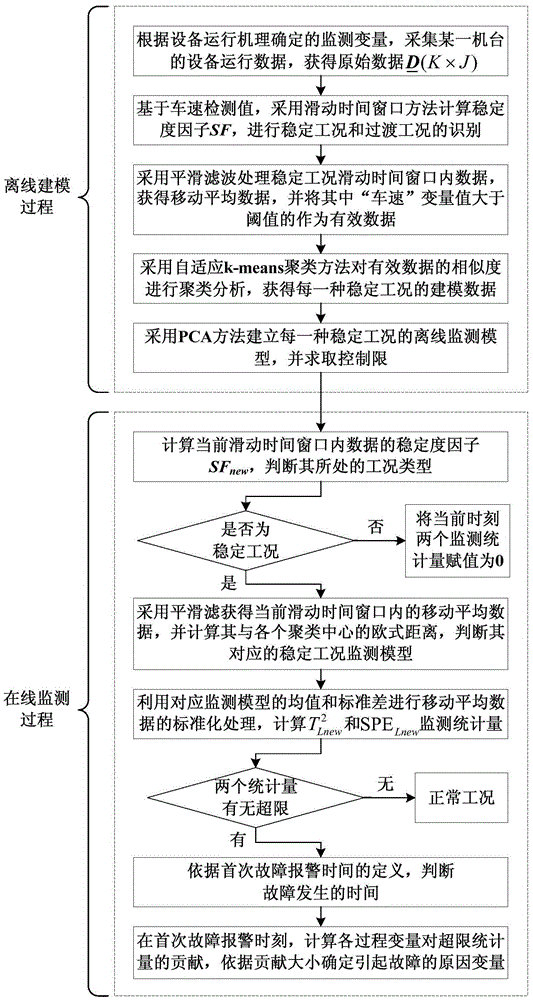

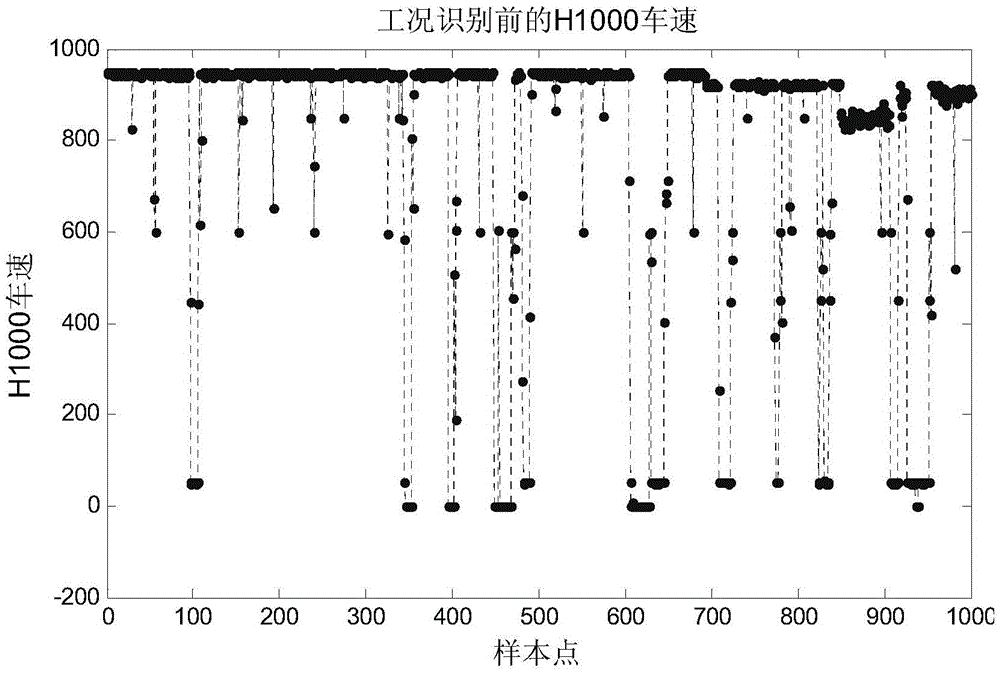

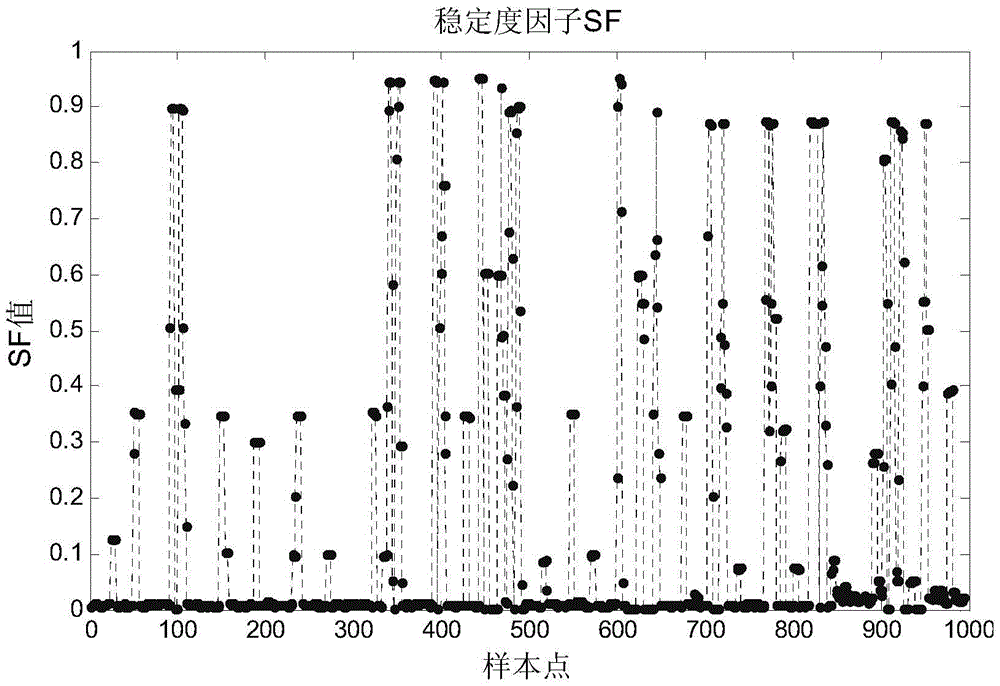

[0067] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. This implementation is a state monitoring and diagnosis method for the ultra-high-speed small box packaging machine H1000 of Italian G.D company. G.D company's ultra-high-speed packaging equipment consists of three parts: small box packaging machine H1000, small box film packaging machine W1000 and box packaging machine BV. Small box packaging machine H1000 is a high-speed continuous motion hard box clamshell packaging machine. Its operation is mainly based on intermittent reciprocating motion and planetary drive with revolution and autobiography. The sticks are packaged in flip-top small boxes in the form of 7-6-7, a total of 20 sticks. The block diagram of the realization of the state monitoring and diagnosis method of the ultra-high-speed small box packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com