Automatic film-cutting and punching machine and film-cutting and punching method applied to edible fungus sticks

A technology of punching machine and film cutting machine, which is applied in botany equipment and methods, applications, gardening, etc., can solve the problems of high labor intensity and low efficiency of manual racking, and achieve reduced labor intensity, safe use, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

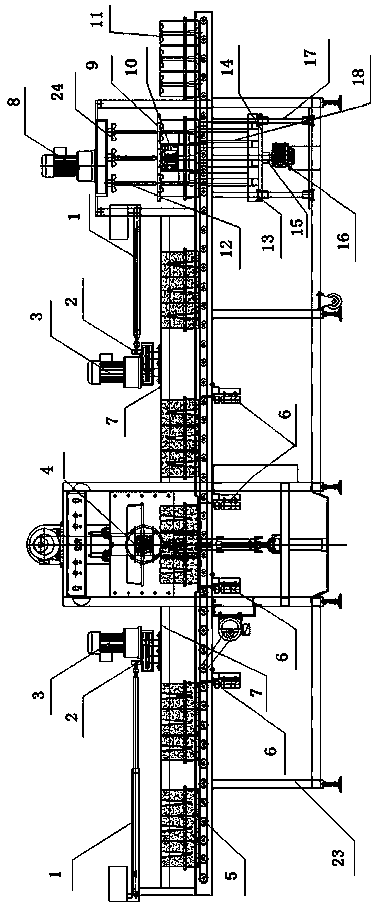

[0029] Embodiment 1, with reference to figure 1 ; An automatic cutting film punching machine suitable for edible mushroom sticks:

[0030] Including the delivery mechanism 5 installed on the frame 23, the first film cutting machine, the basket turning machine 4, the second film cutting machine and the punching machine are arranged successively along the conveying direction of the delivery mechanism 5; before the first film cutting machine On the side, the rear side of the first film cutting machine, the rear side of the basket turning machine, and the frame 23 measured after the second film cutting machine, a blocking device 6 is installed, and the blocking device 6 is connected by a blocking power mechanism and with a blocking power mechanism The blocking block constitutes;

[0031] The first described film cutting machine and the second film cutting machine are arranged on the top of the conveying mechanism 5, and the first film cutting machine and the second film cutting m...

Embodiment 2

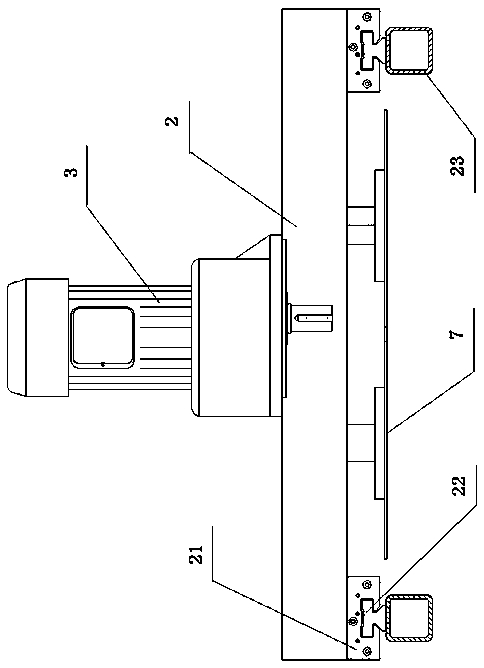

[0033] Embodiment 2, with reference to image 3 , in the automatic film-cutting punching machine applicable to edible mushroom sticks described in embodiment 1: the described film-cutting traveling mechanism is a film-cutting electric cylinder and a guide rail 22 fixed on a frame 23, and the described The film cutting motor 3 is connected with the cutterhead 7 through the transmission gear box 2, and the transmission gear box 2 is fixed on the slide block 21, and the slide block 21 is slidably connected with the guide slide rail 22.

Embodiment 3

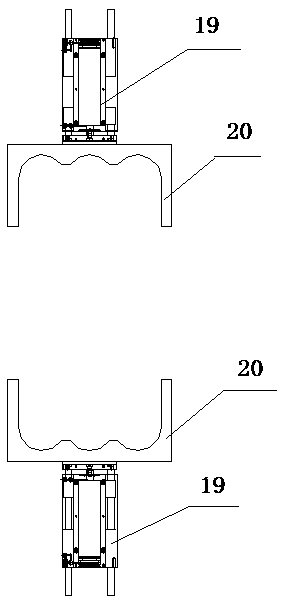

[0034] Embodiment 3, with reference to figure 2 , in embodiment 1 or 2 described in the automatic cutting film punching machine that is applicable to edible fungus bacterium stick: on the frame 23 of the side of the first film cutting machine, the second film cutting machine, righting mechanism is installed, so Said righting mechanism is made up of righting power mechanism 19 and the righting plate 20 that is connected with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com