Defective cigarette cutting and recycling tobacco shreds equipment

A technology for defective cigarettes and shredded tobacco, applied in the field of unqualified cigarette processing equipment, can solve the problems of high equipment maintenance and maintenance costs, low recovery rate of shredded tobacco, huge equipment structure, etc., and achieves convenient and practical operation and maintenance, simple equipment structure, The effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

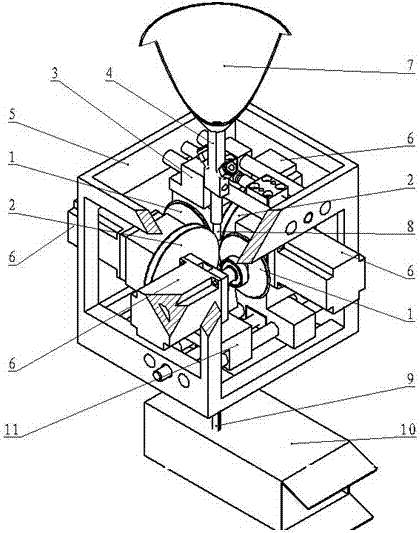

[0014] Embodiment: Recycling shredded tobacco equipment for cutting and processing defective cigarettes.

[0015] The specific structure is that the top of the general support 5 is provided with a defective cigarette collecting and conveying device 7, and a cigarette air pressure conveying device 4 is docked under it, and a double-circle cutter 1 and a double-circle pressure wheel 2 are corresponding to the cigarette outlet, each The rear ends of the circular cutter and the circular pinch wheel are independently connected with a drive motor 6, the center of the general support is equipped with a double circular cutter center distance position adjustment device 3, and the bottom is equipped with a double circular pinch wheel center distance position adjustment device 11. The bottom of the total support is connected with a vibration separation feed bin 10.

[0016] Among them, the axes of the double-circle cutter 1 and the double-circle pressure wheel 2 are on the same plane, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com