Pre-twisting type guide vane assembly method for supercritical steam turbine

An assembly method and steam turbine technology, which are applied to assembly machines, mechanical equipment, engine components, etc., can solve problems such as stress concentration of shrouds and rivet heads, deformation of shroud shrouds and blades, and hidden dangers of safe operation of condensing steam turbines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

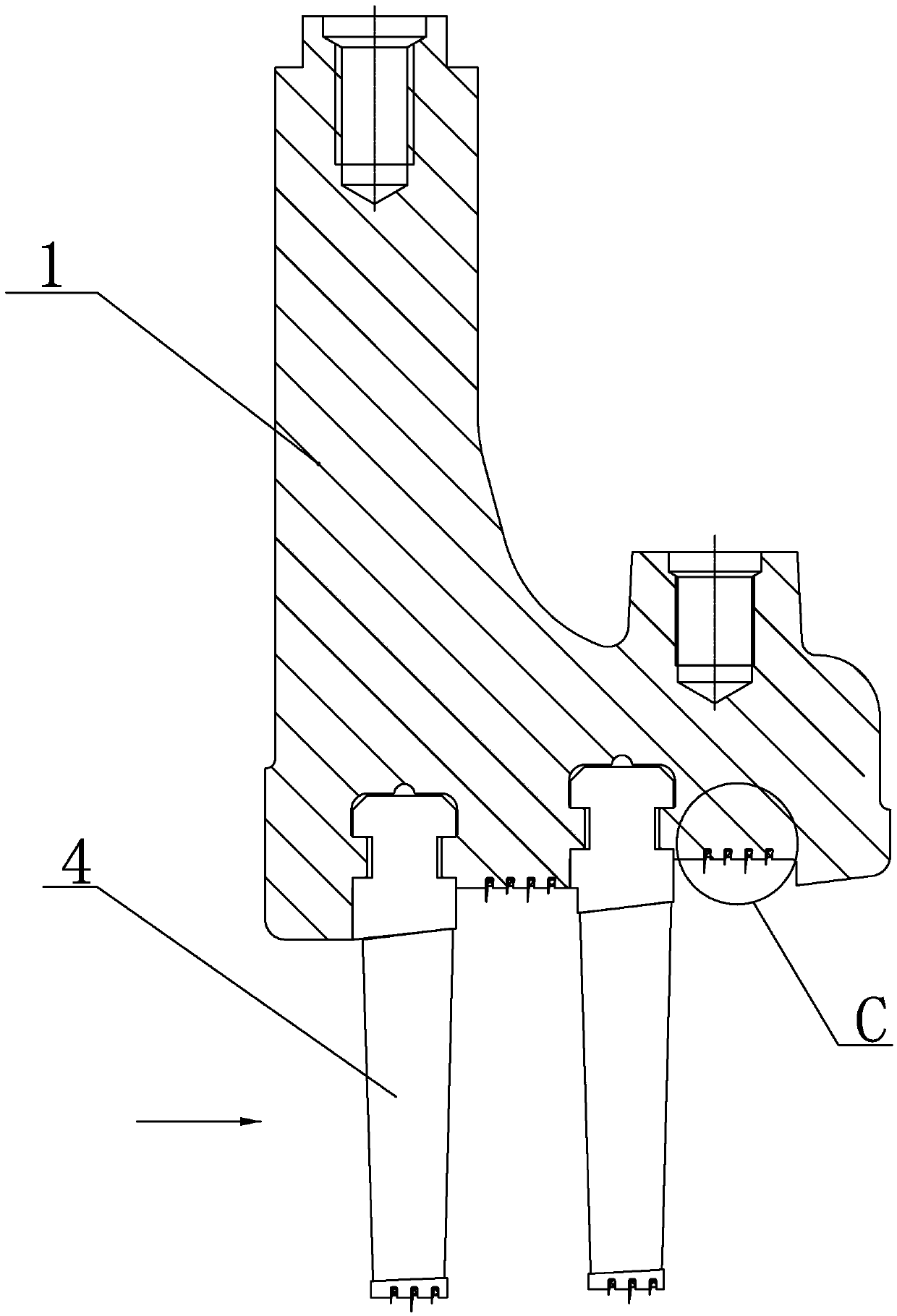

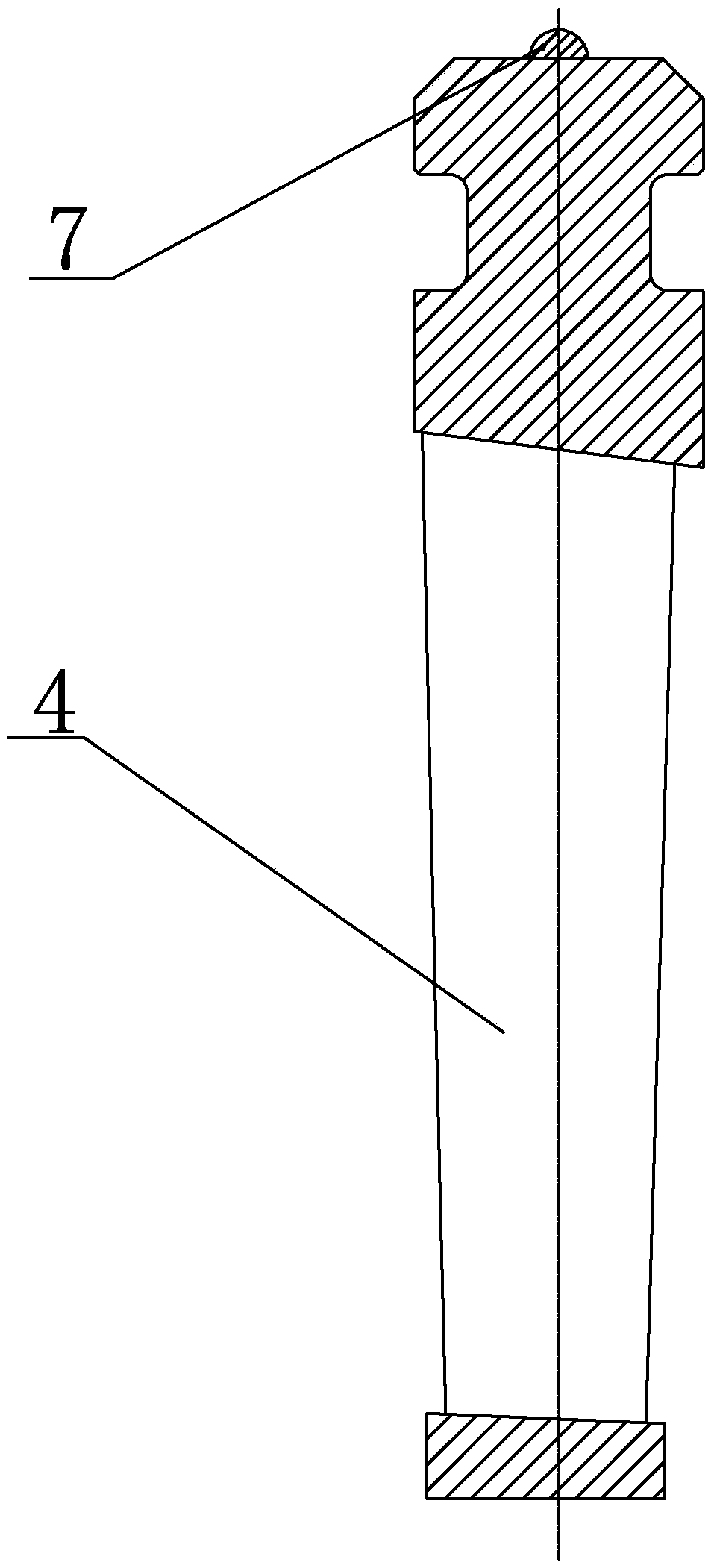

[0028] Specific embodiment one: combine 1 to Figure 9 Describe this embodiment, a kind of supercritical steam turbine pre-twisted guide vane assembly method of this embodiment, it comprises the following steps:

[0029] Step 1: Install the stator baffle cover 1 and the body seal 2;

[0030] Put the stator diaphragm sleeve 1 flat on the cushion box, with the horizontal center facing upwards, install the body seal 2 into the stator diaphragm sleeve 1 in the order from bottom to top, and at the same time install the body seal 2 Insert the locking piece 3 on one side;

[0031] Step 2: Machining body seal piece 2;

[0032] Turning the body seal 2 that has been installed on the stator diaphragm sleeve 1;

[0033] Step 3: Clean the stator partition cover 1 and the body seal 2 after the car processing;

[0034] Lay the steam outlet side of the stator baffle set 1 upwards, clean the separator grooves, guide vanes and other parts of the stator baffle set 1 at all levels, deburr and...

specific Embodiment approach 2

[0047] Specific implementation mode two: combination figure 1 Describe this embodiment, the main body steam seal 2 and the locking plate 3 installed in the leveling step 1 of this embodiment, so that the body steam seal 2 and the locking plate 3 are on the same plane as the horizontal mid-section of the partition cover 1 superior. Other compositions and connections are the same as in the first embodiment.

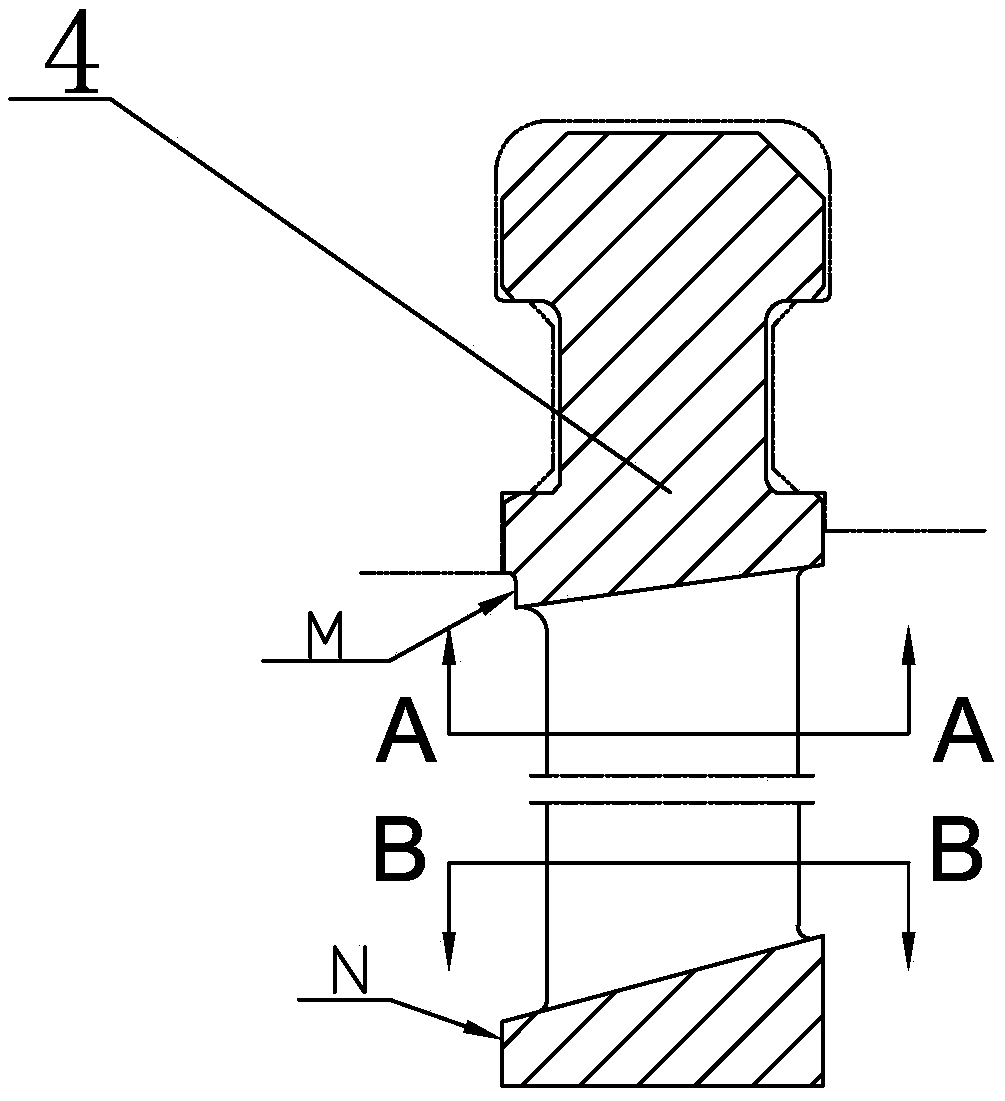

[0048] The structural design of the pre-twisted guide vane has the following characteristics: the outline of the intermediate body of the blade root and the shroud is a parallelogram, and the pitch of the shroud and the blade root is corrected in the design, so that the actual pitch of the blade shroud is higher than the theoretical one. Increase the pitch by a certain amount. The pre-twisted installation first twists the blade shroud relative to the blade root by an angle, and when the shrouds are separated from each other under the action of centrifugal force and therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com