Surface treatment method for single-sided galvanizing of automobile vibration-damping bushing iron pipe

A surface treatment and bushing technology, which is applied in the field of surface treatment technology of single-sided galvanizing of iron pipes for automobile vibration damping bushings, can solve the problems of rubber performance, fatigue life and appearance, and damage the adhesion between rubber and iron or aluminum parts. , the surface of the aluminum inner skeleton is blackened and other problems, so as to eliminate the influence of fatigue, prevent the corrosion of parts, improve the production efficiency and the qualified rate of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A surface treatment method for single-side galvanized iron pipes of automobile vibration-damping bushings, characterized in that it includes the following steps in sequence:

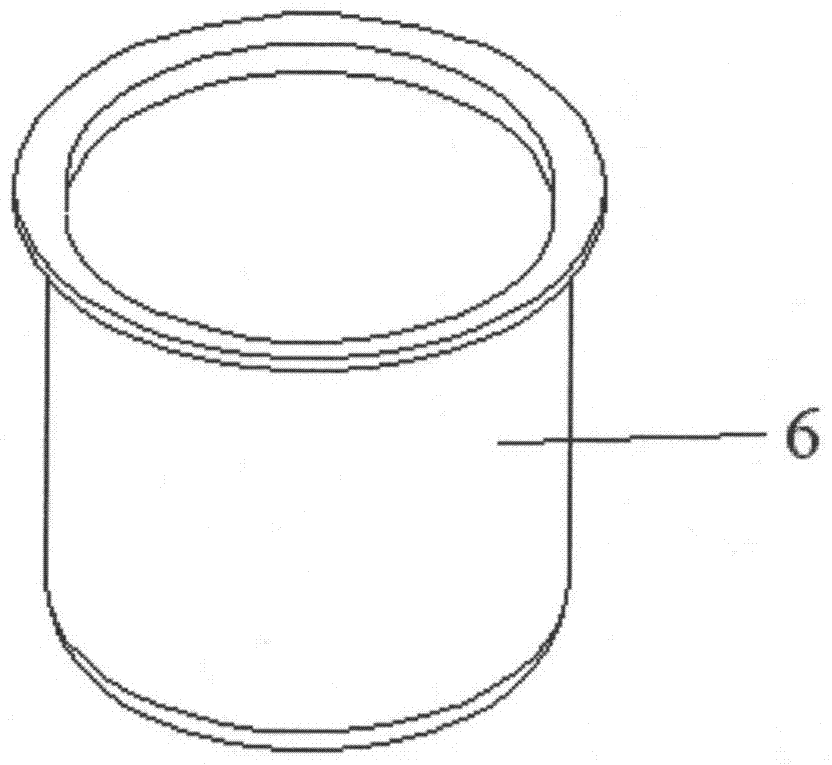

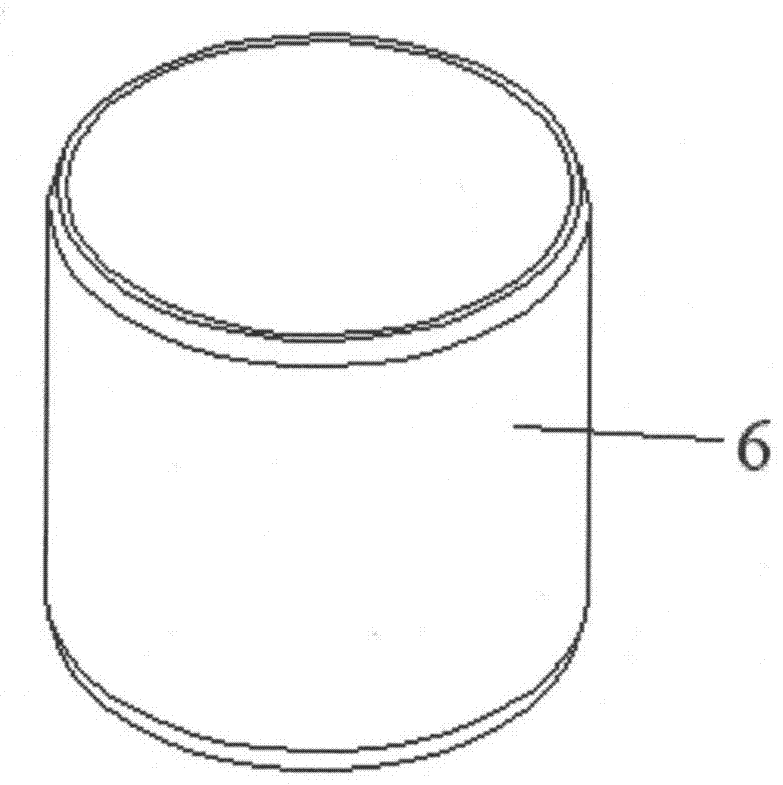

[0032] Step 1): Shot blasting: Use a shot blasting machine to clean the oil, dust, rust, etc. on the surface of the product 6 to make the surface rough and increase the bonding strength between the surface of the product 6 itself and the phosphating film;

[0033] Step 2): Phosphating: Phosphating the surface of the product 6 after shot blasting to form a phosphating film and increase the bonding strength between the phosphating film and the glue;

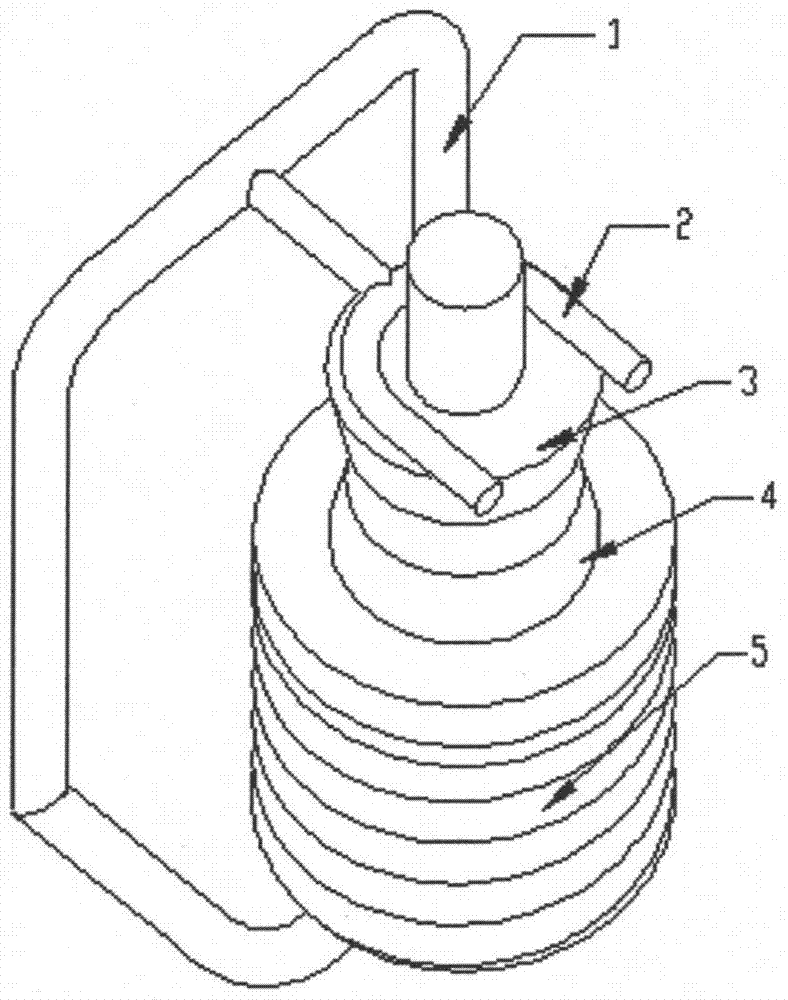

[0034] Step 3): Sealing: Use automobile vibration damping bushing type iron pipe clamps (such as image 3 shown) to clamp the product 6, and use styrene-based thermoplastic elastomers (in this embodiment, beef tendon rubber) to seal the interior of the product 6 to prevent leakage from penetrating into the inner wall of the product 6 during galvanizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com