A drilling machine positioning claw

A drilling machine and claw technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of complex processing technology, low processing accuracy, low production efficiency, etc., and achieve improved positioning efficiency and pressure-bearing Good effect and well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

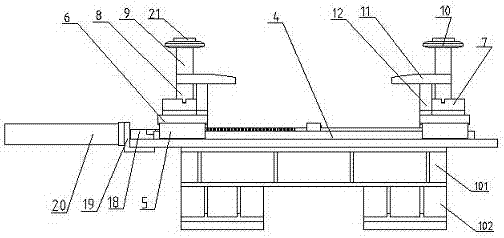

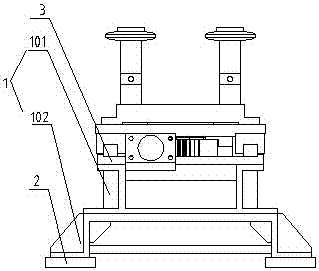

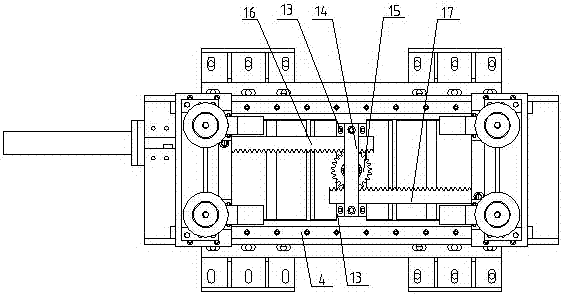

[0018] A positioning jaw of a drilling machine, including a jaw support frame 1, the jaw support frame 1 includes a first support frame 101 and a second support frame 102, and the bottom sides of the first support frame 101 are provided with multiple Bolt holes, the cross-section of the second support frame 102 is an "n"-shaped structure, the top of the second support frame 102 is provided with a plurality of bolt holes, and the bottom two sides are provided with a plurality of bolt holes, through which the first support frame Bolt holes at the bottom of 101 and bolt holes at the top of the second support frame 102 realize the bolt connection between the first support frame 101 and the second support frame 102; the bottom of the second support frame 102 is fixedly connected with a support connecting plate 2; The plate 2 is fixed on the bottom plate of the drilling machine frame; the top of the first support frame 101 is connected with a track plate 3, and the track plate 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com