Double-arm SCARA (selective compliance assembly robot arm) industrial robot

An industrial robot and dual-arm technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as increased assembly costs, unsuitable for large batches, high-precision assembly operations, and loss of operational accuracy, saving time and work High efficiency and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

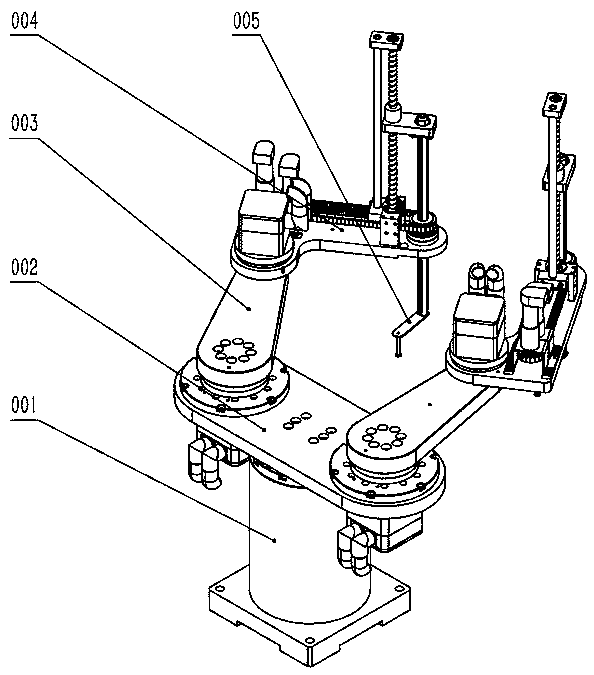

[0027] Such as Figure 1 to Figure 10 As shown, a dual-arm SCARA industrial robot includes a base assembly 001, a shoulder arm assembly 002, a large arm assembly 003, a small arm assembly 004, and an end effector assembly 005, and the shoulder arm assembly 002 is installed on the base assembly 001 , two boom assemblies 003 are installed at both ends of the shoulder-arm assembly 002, a forearm assembly 004 is installed at the end of the boom assembly 003, and an end effector assembly 005 is installed at the front end of the forearm assembly 004.

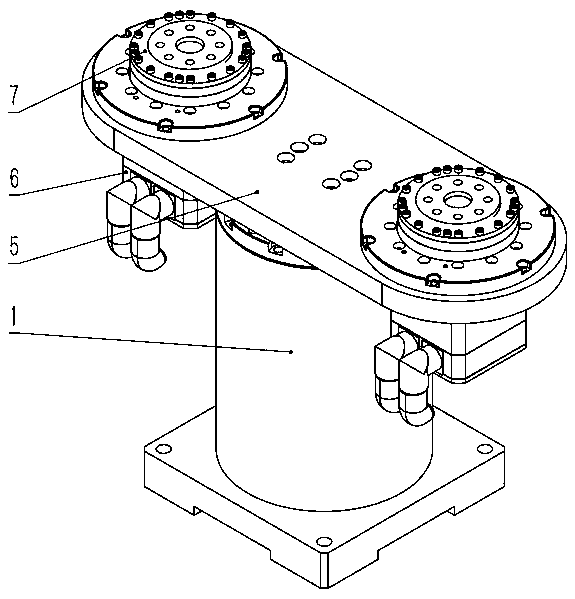

[0028] The base assembly 001 includes a base 1, a first motor 2, a first reducer 3, and a first mounting plate 4; the first motor 2 is connected to the first reducer 3 by screws, and the first reducer 3 is connected to the first reducer 3. The transmission shaft of the first motor 2 is connected by a flat key, the first speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com