Clamping claw type manipulator device with closing cover

A closed cover and claw-type technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of inaccurate grasping, falling and falling of parts in the barrel, and achieve accurate grasping and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

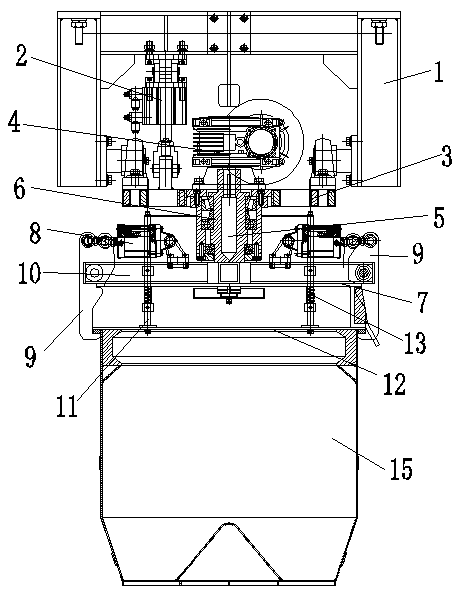

[0011] Combine below figure 1 Specific description embodiment:

[0012] like figure 1 As shown, the claw-type manipulator device with a closed cover, the claw-type manipulator device with a closed cover includes a frame 1, the frame 1 is provided with a master cylinder 2, and the output end of the master cylinder 2 is connected to a Plate 3, the upper part of the connecting plate 3 is connected with an electric hoisting device 4, and the output end of the electrical hoisting device 4 passes through the connecting plate 3 to hang an anti-fall bar 5; the lower part of the connecting plate 3 The work piece 7 is connected to the column 6, the work piece 7 and the column 6 are hollow, and the work piece 7 and the column 6 are connected at the joint; the upper part of the work piece 7 is provided with a claw cylinder 8, and the output end of the claw cylinder 8 There are claws 9 connected, and the claws 9 are hingedly arranged at the end of the work piece 7. The hinge point is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com