Injection molding process of mobile phone shell

An injection molding process, a technology for mobile phone casings, applied in coatings and other directions, can solve the problems affecting the yield and uneven surface bulges of mobile phone casings, and achieve the effect of improving product yield and ensuring flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

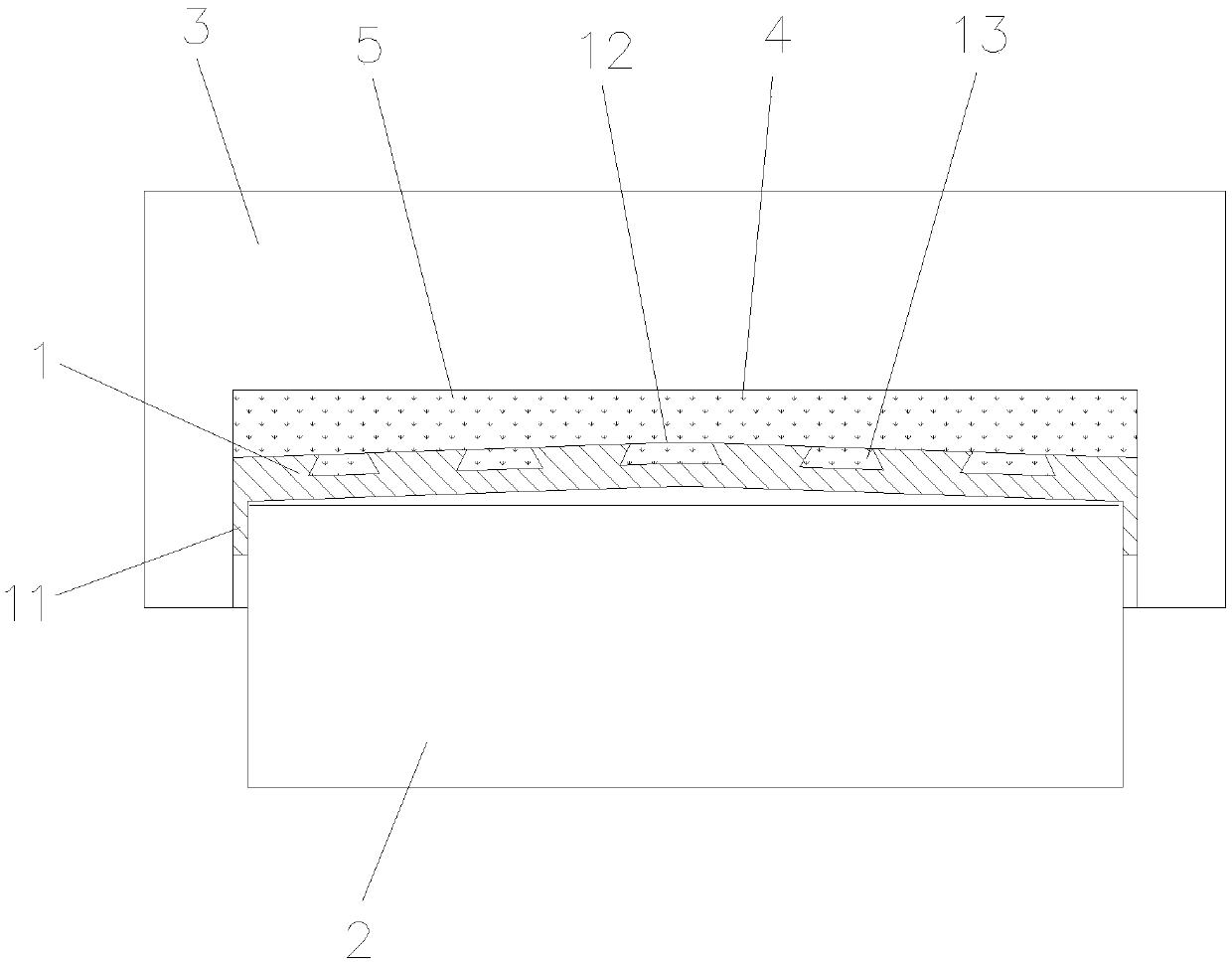

[0021] Such as figure 1 Shown, a kind of injection molding process of mobile phone shell, comprises the following steps:

[0022] (1) Make a metal lining 1 with a downward flanging 11 on the periphery and a metal lining 1 that protrudes from the periphery to the center at a small angle;

[0023] (2) Set it on the punch 2 of the injection molding machine by means of the downward flanging 11 around the metal lining 1, and let the convex part 12 of the metal lining 1 face the die 3 of the injection molding machine;

[0024] (3) After the injection molding machine is closed, the molten plastic 4 is injected into the mold cavity 5 by pressure, and then bonded with the metal lining 1 to form a metal reinforced plastic shell;

[0025] (4) Cool the injection-molded metal-reinforced plastic shell at room temperature. During the cooling process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com