Method for manufacturing terahertz waveguide preform by means of 3D printing technology

A 3D printing and preform technology, applied in the field of terahertz waveguide preparation, can solve the problem of single production material, and achieve the effect of low cost, simple structure, and improved design dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The terahertz waveguide prefabricated rod is manufactured by adopting the invention.

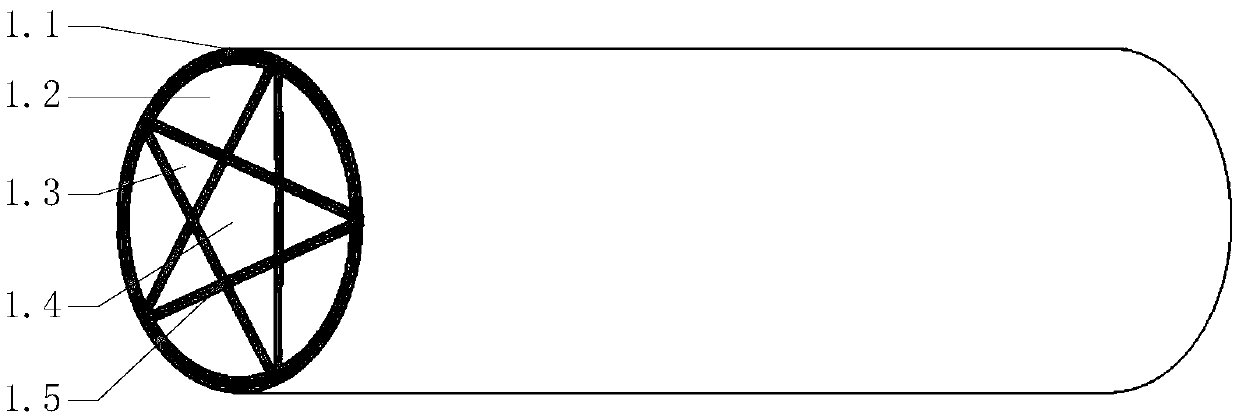

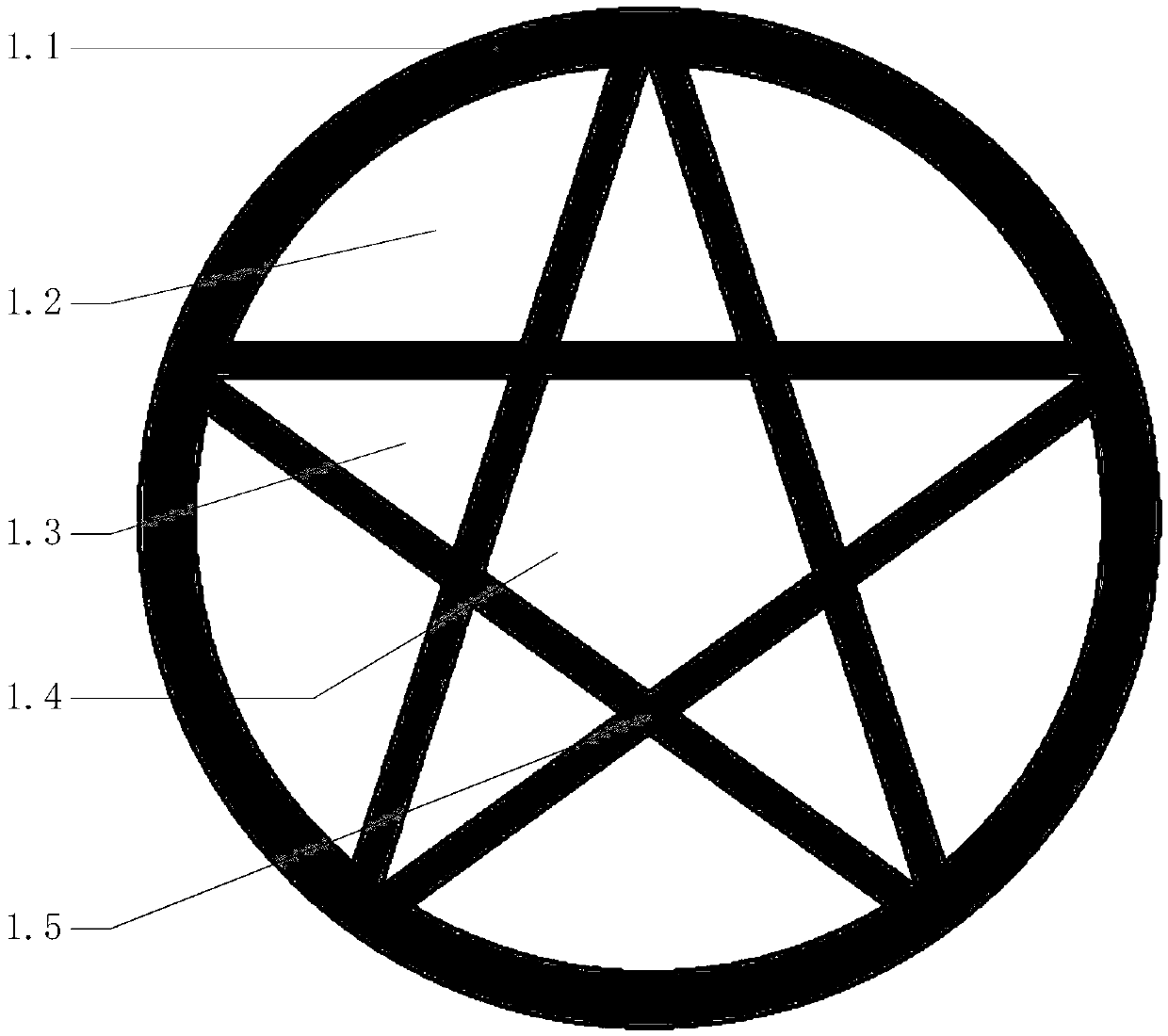

[0019] First, using AutoCAD software, follow the Figure 1.2 The design structure shown shows the cross-section of the terahertz waveguide preform, and its structure includes preform cladding 1.1, preform outer air holes 1.2, preform inner air holes 1.3, preform air core 1.4 and preform Internal regular five-pointed star structure 1.5. Among them, the preform cladding layer 1.1 and the preform internal structure 1.5 are made of cycloolefin copolymer branded as ZEONEX, and the rest is air. Among them, the diameter of the preform is 11 mm, the thickness of the preform cladding 1.1 is 0.5 mm, and the thickness of the supporting structure plate of the internal regular five-pointed star structure 1.5 is 0.3 mm. Then, save it as a lithographic format file. Furthermore, the file in the lithographic printing format was transcoded into a coordinate file of the 3D printer via the transcoding...

Embodiment 2

[0021] The terahertz waveguide prefabricated rod is manufactured by adopting the invention.

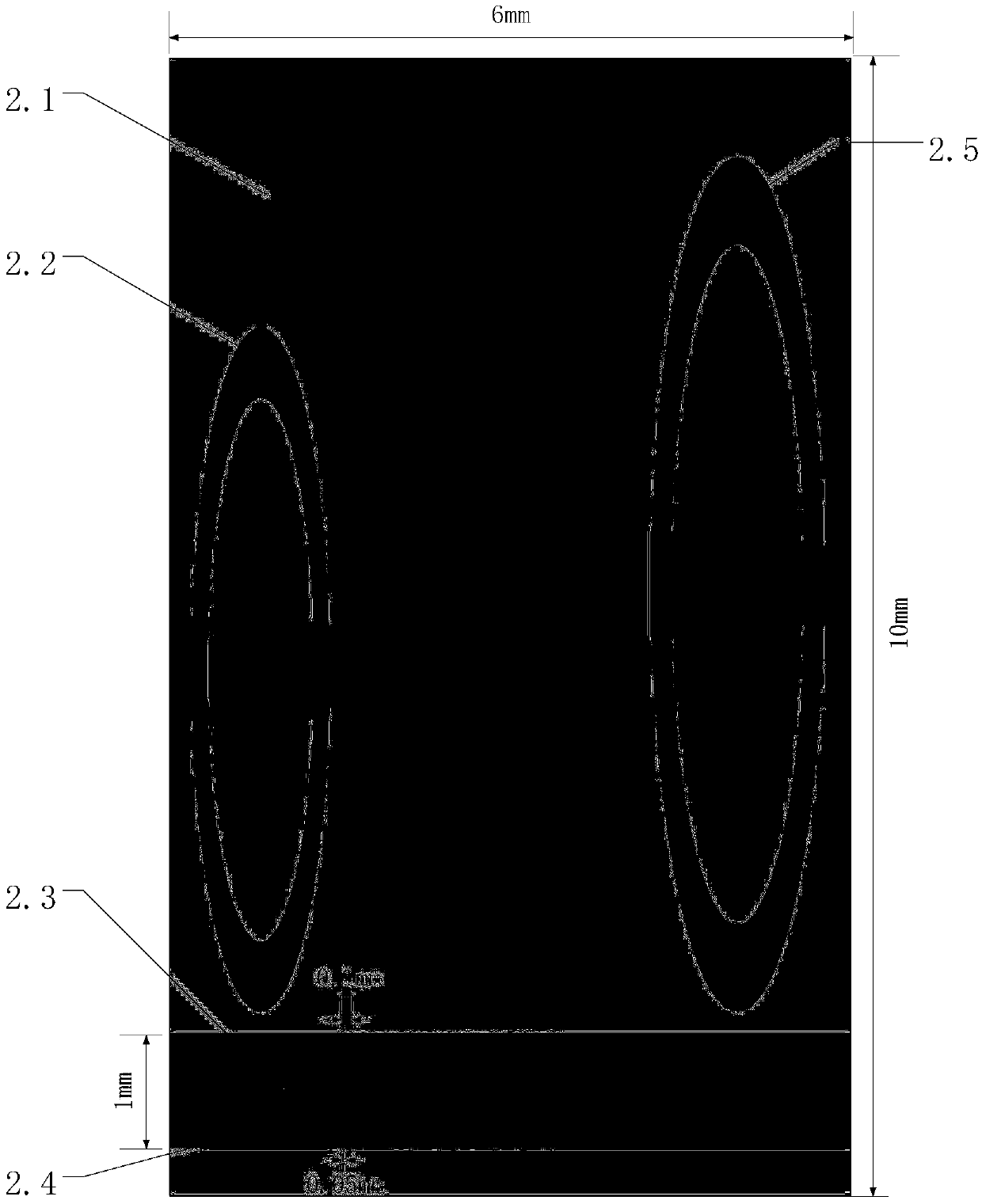

[0022] Using AutoCAD software, according to Figure 2.1 The shown structure shows the side of the terahertz waveguide preform, and its structure includes a substrate 2.1, a first-stage microring resonator 2.2, a straight waveguide 2.3, a grating structure 2.4, and a second-stage microring resonator 2.5. The first-stage microring resonator 2.2, the straight waveguide 2.3, and the second-stage microring resonator 2.5 are made of polycarbonate (PC); the grating structure 2.4 is made of metal tin. Among them, the 2.2 part of the first-stage micro-ring resonator, the major axis of the outer ring ellipse is 6 mm, the major axis of the inner ring ellipse is 4.8 mm, and the inner and outer ring ellipses are concentric; the second-stage micro-ring resonator part 2.5, the major axis of the outer ring ellipse 7.5 mm, the major axis of the inner ellipse is 6 mm, and the inner and outer ellipses ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com